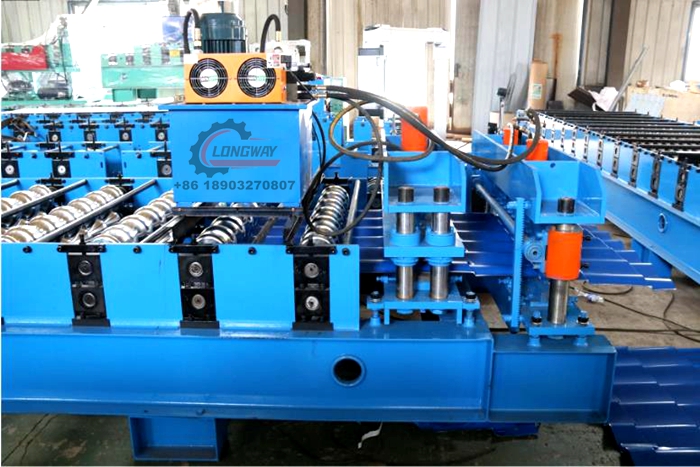

metal roof sheet bending machine manufacturers

The Importance of Metal Roof Sheet Bending Machines A Guide for Manufacturers

In the rapidly evolving construction industry, metal roofs have emerged as a popular choice due to their durability, energy efficiency, and aesthetic appeal. As the demand for metal roofing continues to soar, the need for specialized machinery, particularly metal roof sheet bending machines, has become increasingly significant. This article explores the importance of these machines, their features, and what manufacturers should look for when sourcing them.

Metal roof sheet bending machines are essential for shaping and forming metal sheets into the desired profile for roofing applications. These machines can create various designs, allowing manufacturers to offer diversified products to meet the needs of customers. The versatility of bending machines is critical, as it enables the production of sheets that cater to different architectural styles and environmental requirements.

One of the primary advantages of using a metal roof sheet bending machine is the precision it offers. Modern machines are equipped with advanced technology, including numerical control (CNC) systems, which enhance accuracy and reduce waste. This precision not only results in better quality products but also improves efficiency on the production line, allowing manufacturers to deliver larger quantities of finished goods within shorter timeframes.

Additionally, investing in a high-quality bending machine can lead to significant cost savings in the long run. While the initial investment may be substantial, the durability and efficiency of these machines often outweigh the costs. They require less maintenance and are less prone to breakdowns, which minimizes downtime and maximizes productivity. Furthermore, the ability to produce custom thicknesses and profiles on demand means that manufacturers can respond quickly to market trends and customer needs.

metal roof sheet bending machine manufacturers

When sourcing a metal roof sheet bending machine, manufacturers should consider several key factors to ensure they choose the right equipment for their operations. First, the machine’s capacity, including the maximum bending length and thickness, should align with the manufacturer’s production requirements. This capacity is crucial for handling larger projects or high-volume orders efficiently.

Another vital aspect to examine is the machine’s technology and features. Look for machines equipped with user-friendly interfaces, automated features, and advanced safety systems. Automation can enhance productivity by reducing the need for manual intervention, thus allowing operators to focus on other critical tasks.

Moreover, sourcing from reputable manufacturers is essential. Established companies often provide better customer support, warranty services, and training programs. This support can be invaluable, especially for smaller manufacturers who may not have extensive experience operating complex machinery.

Support for customization is another factor that can set a manufacturer apart from the competition. Finding a bending machine that allows for easy adjustments and customizations will enable manufacturers to respond swiftly to unique client requests and evolving market demands.

In conclusion, metal roof sheet bending machines play a pivotal role in the production of metal roofing materials. Their precision, efficiency, and versatility make them indispensable for modern roofing manufacturers. By carefully evaluating machine capacity, technology features, and the reputation of suppliers, manufacturers can invest in equipment that ensures long-term success and meets the growing demands of the construction industry. As the market for metal roofing continues to expand, the importance of these machines will only increase, reinforcing their role in the future of construction.