Фев . 18, 2025 10:32

Back to list

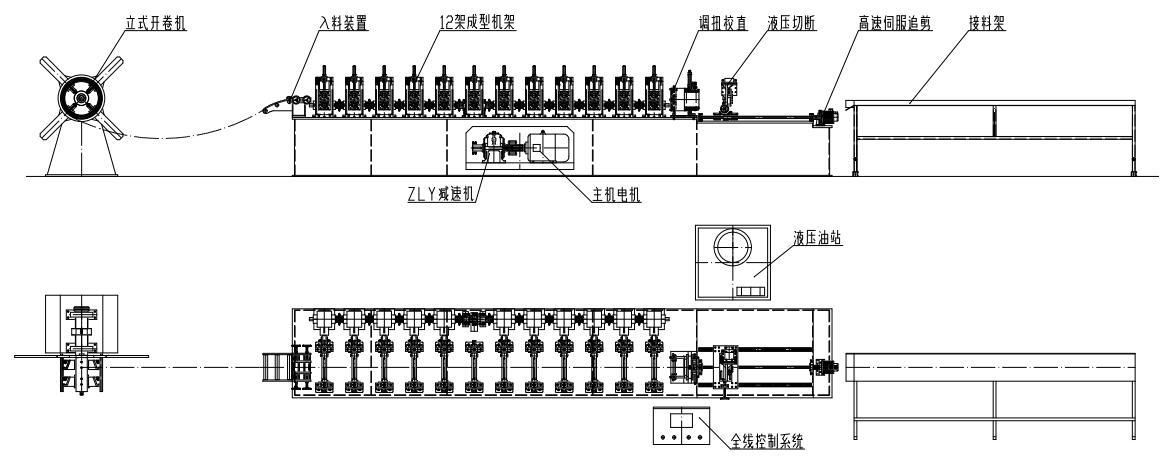

keel roll forming machine for sale

For those considering entering the world of roll forming or upgrading their current machinery, the keel roll forming machine represents an advanced, efficient solution. This particular piece of equipment has garnered attention in recent years due to its ability to produce high-quality metal profiles essential in various construction applications. Understanding the profound impact that a keel roll forming machine can have on production is crucial.

Another fundamental consideration lies in the post-purchase support offered by manufacturers or sellers. Reliable after-sales support ensures that any technical issues are resolved promptly, minimizing downtime and maintaining productivity. This support may include services such as installation guidance, maintenance tips, and access to spare parts—all of which contribute to the machine's long-term operational viability. Trustworthiness plays a pivotal role in establishing confidence in these machines. It is essential for businesses to conduct thorough research and source equipment from reputable manufacturers known for their commitment to quality and compliance with international standards. Engaging with peer reviews, industry forums, and case studies of previous implementations can provide invaluable insights into selecting the right machine. The keel roll forming machine stands as an authoritative tool in modern metalworking applications. Its implementation does not only reflect a commitment to cutting-edge technology but also signifies an investment in efficiency and quality. As industries aim to meet growing construction demands worldwide, the dependability and advanced features of keel roll forming machines will continue to make them indispensable assets in the manufacturing sector. In conclusion, leveraging a keel roll forming machine for metal profile production is an investment in both present productivity and future growth opportunities. The combination of advanced engineering, operational efficiency, and customizable features underscores a forward-thinking approach within the construction and metalworking domains. When businesses align with trusted suppliers and commit to cutting-edge technology, they not only enhance their operational capabilities but also set themselves on a path of sustained innovation and market leadership.

Another fundamental consideration lies in the post-purchase support offered by manufacturers or sellers. Reliable after-sales support ensures that any technical issues are resolved promptly, minimizing downtime and maintaining productivity. This support may include services such as installation guidance, maintenance tips, and access to spare parts—all of which contribute to the machine's long-term operational viability. Trustworthiness plays a pivotal role in establishing confidence in these machines. It is essential for businesses to conduct thorough research and source equipment from reputable manufacturers known for their commitment to quality and compliance with international standards. Engaging with peer reviews, industry forums, and case studies of previous implementations can provide invaluable insights into selecting the right machine. The keel roll forming machine stands as an authoritative tool in modern metalworking applications. Its implementation does not only reflect a commitment to cutting-edge technology but also signifies an investment in efficiency and quality. As industries aim to meet growing construction demands worldwide, the dependability and advanced features of keel roll forming machines will continue to make them indispensable assets in the manufacturing sector. In conclusion, leveraging a keel roll forming machine for metal profile production is an investment in both present productivity and future growth opportunities. The combination of advanced engineering, operational efficiency, and customizable features underscores a forward-thinking approach within the construction and metalworking domains. When businesses align with trusted suppliers and commit to cutting-edge technology, they not only enhance their operational capabilities but also set themselves on a path of sustained innovation and market leadership.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products