faster speed forming machine for parante metalico

Faster Speed Forming Machine for Parante Metalico Revolutionizing Metalwork

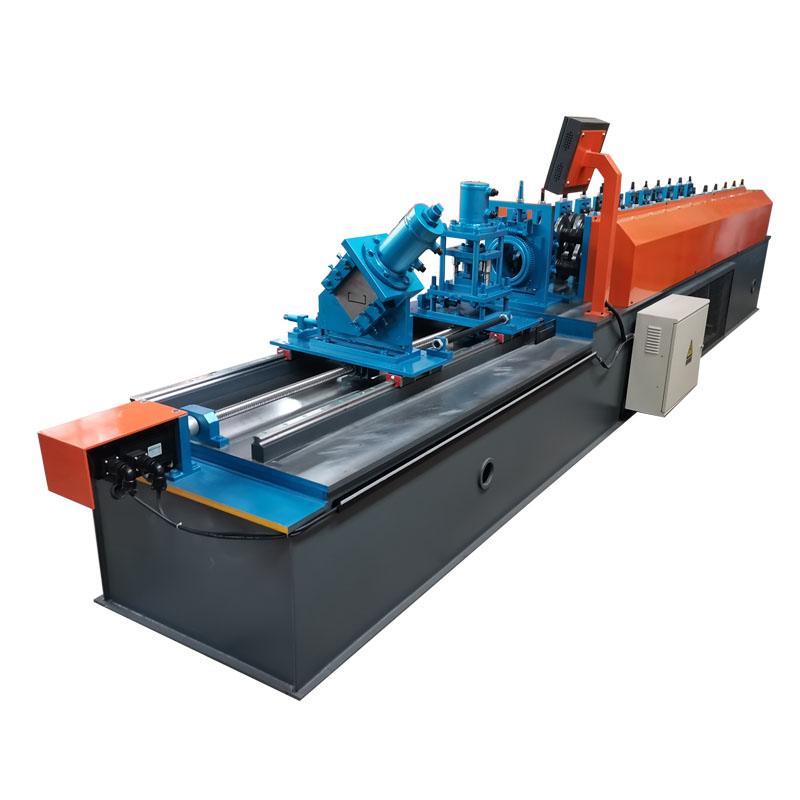

The manufacturing industry has witnessed a significant transformation in recent years, with technological advancements enhancing production processes and efficiency. Among these innovations, the faster speed forming machine for parante metalico (metal brackets) stands out as a game-changer. This state-of-the-art machinery is designed to streamline the creation of metal brackets, meeting the increasing demand for high-quality components in various sectors, including construction, automotive, and electronics.

Understanding Parante Metalico and Its Importance

Parante metalico, or metal brackets, play a crucial role in both structural and functional applications. These components are essential for supporting and connecting different parts of a structure, ensuring stability and durability. Their uses span a wide array of industries, from reinforcing building frames to securing electrical systems. As a result, manufacturers require efficient solutions to produce these components promptly and accurately.

The Evolution of Forming Technology

Traditional metal forming methods, while effective, often involve lengthy processes that can lead to delays in production and increased labor costs. The advent of faster speed forming machines marks a pivotal shift in this paradigm. These machines utilize advanced technologies such as automated feeding systems, precision cutting tools, and high-speed stamping, which allow for rapid production without sacrificing quality.

Key Features of Faster Speed Forming Machines

1. High-Speed Operation With the capability to produce hundreds of units per hour, these machines significantly reduce lead times. This rapid production capability is particularly beneficial for industries that operate on tight schedules and cannot afford downtime.

2. Precision Engineering Advanced computerized controls ensure that each metal bracket is formed to precise specifications. This level of accuracy minimizes waste and enhances product quality, leading to fewer defects and rework.

faster speed forming machine for parante metalico

3. Versatility Faster speed forming machines are designed to handle a variety of materials and sizes. This versatility enables manufacturers to cater to different client needs and adapt quickly to market changes.

4. Energy Efficiency Many modern machines incorporate energy-saving technologies that reduce electricity consumption. This not only lowers operational costs but also aligns with the growing emphasis on sustainability in manufacturing.

5. User-Friendly Interfaces The latest machines come equipped with intuitive interfaces that allow operators to easily control and monitor the production process. This reduces the learning curve for new employees and enhances overall productivity.

Impact on the Metalworking Industry

The introduction of faster speed forming machines has profound implications for the metalworking industry. Manufacturers can now meet increased demand without compromising on quality or efficiency. Moreover, the ability to produce large volumes of parante metalico in less time opens up opportunities for businesses to expand their product offerings and enter new markets.

Furthermore, the technological advancements associated with these machines encourage innovation in design and engineering. With the time saved in production, companies can dedicate more resources to research and development, leading to the creation of new, improved metal components.

Conclusion

In conclusion, the faster speed forming machine for parante metalico represents a significant leap forward in metal manufacturing technology. By combining speed, precision, and versatility, it addresses the pressing needs of industries that rely on metal brackets while setting a new standard for production efficiency. As manufacturers continue to adopt these advanced machines, the landscape of the metalworking industry will undoubtedly evolve, driving growth and innovation for years to come. Embracing such technological advancements is essential for businesses aiming to stay competitive in today’s fast-paced market.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025