Top Manufacturers of Fascia Roll Forming Equipment for Efficient Production

The Evolution and Importance of Fascia Roll Forming Machines in Manufacturing

In today's fast-paced manufacturing environment, the demand for efficient, high-quality production processes has never been more critical. One of the technological advancements that have significantly contributed to the efficiency of manufacturing is the fascia roll forming machine. These machines are designed to create continuous lengths of fascia, a key component in roofing and siding applications, and their importance is evident across various industries.

What is a Fascia Roll Forming Machine?

Fascia roll forming machines are specialized equipment used to fabricate fascia boards from metal sheets or coils. The process involves feeding metal into a series of rollers that shape it into the desired profile. The machines can produce fascia in various materials, including aluminum, steel, and even vinyl, allowing manufacturers to meet diverse customer requirements. The automation of this process not only improves production speed but also ensures uniformity and consistency in the finished products.

The Role of Fascia in Construction

Fascia boards serve both aesthetic and functional purposes in construction. They are the horizontal boards installed at the eaves of a roof, providing a finishing touch to the building’s exterior while serving as a vital part of the roofing system. Fascia helps protect the roof and underlying structures from water damage, pests, and harsh weather conditions. Additionally, they serve as a mounting point for gutter systems, which are crucial for channeling rainwater away from the foundation of the building.

Advancements in Roll Forming Technology

The development of fascia roll forming machines has come a long way over the years. Modern machines are equipped with advanced features such as computer numerical control (CNC) systems, allowing for precise adjustments and automation of production. This technology enables manufacturers to quickly switch between different profiles and run small batches efficiently—an essential capability in today’s market, where customization and adaptability define success.

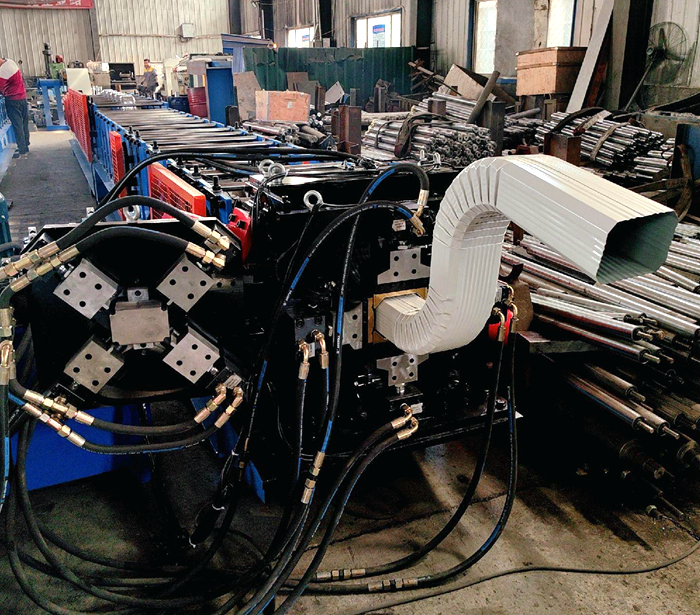

fascia roll forming machine companies

Moreover, manufacturers are increasingly focused on sustainability. Contemporary roll forming machines are designed to minimize waste by optimizing material usage. With features that recycle scrap metal and reduce energy consumption, manufacturers can not only lower their operational costs but also enhance their green credentials, appealing to environmentally conscious consumers.

Choosing the Right Fascia Roll Forming Machine Company

When selecting a fascia roll forming machine company, it is crucial to consider factors such as experience, technology, and customer service. Leading companies often have a proven track record and a portfolio showcasing their capabilities. Furthermore, they invest in research and development to stay ahead of industry trends, ensuring their machines are equipped with the latest technology.

Customer support is also a critical aspect. Reliable manufacturers offer robust support for their machines, including installation, training, and ongoing maintenance services. This support can significantly impact the efficiency of production and the lifespan of the equipment.

The Future of Fascia Roll Forming Machines

As the construction industry evolves, the demand for innovative and efficient production methods will continue to grow. The fascia roll forming machine market is expected to expand in the coming years, driven by the increasing need for sustainable building practices and energy-efficient materials. Companies that invest in the latest technology and offer high-quality machinery will likely lead the way in this competitive landscape.

In conclusion, fascia roll forming machines represent a vital component of modern manufacturing, particularly in the construction sector. Their ability to produce high-quality, custom fascia efficiently is crucial for meeting market demands. As technology continues to advance, these machines will play an even more significant role in shaping the future of building construction and design.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025