Custom Roll Forming Machine for Precision Metal Fabrication and Versatile Applications

The Custom Roll Former Machine Revolutionizing Metal Fabrication

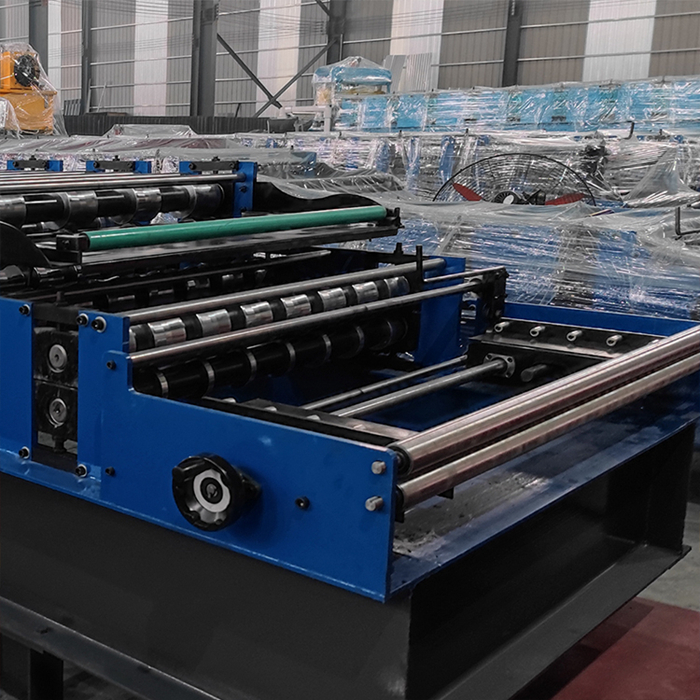

In recent years, the demand for precision-engineered components in various industries has surged, prompting manufacturers to seek innovative solutions that enhance efficiency and productivity. One such solution is the custom roll former machine, a piece of equipment that has transformed the landscape of metal fabrication. This advanced technology not only offers precision and speed but also the flexibility to produce a wide range of profiles tailored to specific applications.

Understanding Roll Forming

Roll forming is a continuous bending operation where long strips of metal, usually coiled steel or aluminum, are transformed into desired profiles by passing through a series of forming rolls. The process involves feeding the raw material through various sets of rollers, each progressively shaping the metal until the final design is achieved. Unlike traditional stamping or machining methods, roll forming is known for its ability to produce long lengths of uniform cross-sections, making it an excellent choice for a variety of industries such as construction, automotive, and HVAC.

The Customization Aspect

What sets the custom roll former machine apart is its ability to be tailored to meet specific production needs. Manufacturers can design bespoke roll forming systems that accommodate unique sizes, shapes, and materials. Customization can involve adjusting the number of passes through the rollers, modifying the roll profiles, or even integrating additional features such as cutting and bending. This level of flexibility allows businesses to respond quickly to changing market demands and customer specifications, ensuring they remain competitive.

Advantages of Custom Roll Former Machines

1. Efficiency and Production Speed Custom roll forming machines are designed for high-speed production, allowing manufacturers to produce large quantities of parts in a relatively short amount of time. The continuous nature of the process means that downtime is minimized, and production can be scaled up or down based on demand.

custom roll former machine

2. Cost-Effectiveness While the initial investment in a custom roll former may be significant, the long-term savings it offers can be substantial. The efficiency of the process, combined with minimal material waste and reduced labor costs, leads to lower overall production expenses. Furthermore, the ability to produce complex shapes without the need for secondary operations minimizes additional costs.

3. High-Quality Output Precision is paramount in metal fabrication, and custom roll former machines excel in producing high-quality parts with tight tolerances. The controlled environment of the roll forming process ensures consistent results, reducing the likelihood of defects and enhancing the overall product quality.

4. Material Versatility These machines can work with a variety of materials, including different grades of steel, aluminum, and even some plastics. This versatility allows manufacturers to expand their product offerings and meet diverse customer needs without investing in multiple pieces of equipment.

5. Sustainability In today’s increasingly eco-conscious business environment, sustainability is a critical consideration. Custom roll forming is inherently resource-efficient, with minimal waste generated during the process. Additionally, the durability of roll-formed products often results in a longer lifespan, reducing the need for replacements and further contributing to sustainability efforts.

Applications of Custom Roll Forming

Custom roll former machines are used across various sectors, producing components like roof panels, wall studs, electrical enclosures, and automotive parts. In the construction industry, the ability to create customized profiles allows builders to design structures that are both functional and aesthetically pleasing. Similarly, in the automotive sector, precise and lightweight components can improve fuel efficiency and vehicle performance.

Conclusion

The custom roll former machine represents a significant advancement in metal fabrication technology, providing businesses with the tools they need to innovate and compete in a dynamic marketplace. By combining efficiency, quality, and customization, these machines not only streamline production processes but also open up new avenues for product development. As industries continue to evolve, the role of custom roll forming will undoubtedly become more critical in meeting the modern demands of manufacturing. Investing in this technology can yield substantial benefits for those looking to stay ahead of the competition and adapt to an ever-changing industrial landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025