corrugated roof sheet making machine company

The Evolution and Impact of Corrugated Roof Sheet Making Machines

In today’s construction and manufacturing industries, efficiency and precision are paramount. One machine that plays a vital role in this context is the corrugated roof sheet making machine. These machines are designed to produce corrugated sheets, which are widely used in commercial, industrial, and residential buildings due to their durability, lightweight nature, and cost-effectiveness.

Understanding Corrugated Roof Sheets

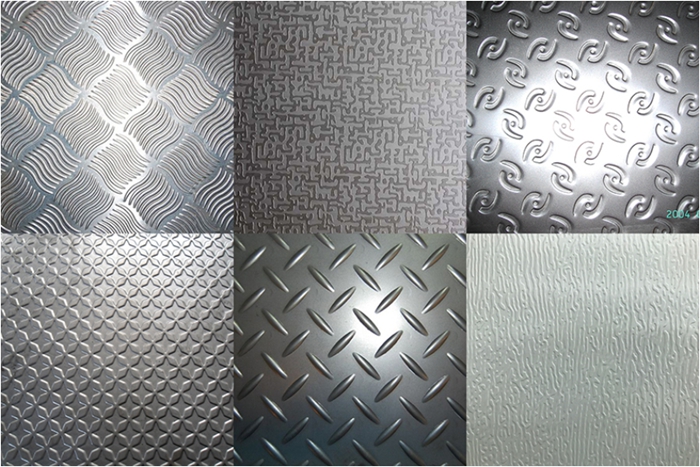

Corrugated roof sheets are panels characterized by their wavy or ridged pattern. This design increases the sheet’s strength while minimizing the amount of material needed, making it an economically favorable option. Their applications range from roofs and walls to sidings and warehouses. Made typically from materials such as galvanized steel, aluminum, or plastic, these sheets offer excellent resistance to adverse weather conditions, making them a popular choice in many regions around the globe.

The Role of Corrugated Roof Sheet Making Machines

The corrugated roof sheet making machine is central to the production of these sheets. The machine uses a combination of rolling, cutting, and folding processes to create the desired corrugated shape. Key components of these machines often include a feeding system, a molding machine, and a cutting device.

1. Feeding System This is where raw materials, such as steel or plastic, are fed into the machine. The quality of the input material significantly influences the final product’s durability and strength.

2. Molding Unit The heart of the machine, the molding unit, shapes the material into corrugated forms. This unit employs rollers that create the characteristic ridges in the sheets. The precision of this process is crucial, as it ensures uniformity in size and shape across all sheets produced.

3. Cutting Device Once the sheets are formed, they must be cut to the desired lengths. Advanced machines feature automated cutting systems that enhance precision and reduce waste.

Advantages of Using Corrugated Roof Sheet Making Machines

corrugated roof sheet making machine company

1. Efficiency Modern machines are designed for high-speed operations, allowing manufacturers to meet growing market demands with minimal downtime. This efficiency translates to reduced labor costs and increased productivity.

2. Quality Control Advanced technology in corrugated roof sheet making machines allows for better quality control. With features like automated adjustment systems, machines can consistently produce sheets that meet specific standards, reducing the need for manual inspection and rework.

3. Customization Many machines are adaptable, enabling manufacturers to produce sheets of various sizes, colors, and materials, catering to diverse customer needs. This flexibility can enhance competitiveness in the market.

4. Sustainability With increasing environmental awareness, manufacturers are looking for sustainable options. Corrugated roof sheet making machines can produce sheets from recycled materials, contributing to a circular economy and minimizing waste.

Market Outlook and Innovations

As urbanization continues to accelerate globally, the demand for corrugated roof sheets is expected to rise. The construction sector is evolving, with an increased focus on sustainable building materials and technologies. Innovations such as automation, artificial intelligence, and machine learning are beginning to influence the design and functionality of corrugated roof sheet making machines.

Futuristic machines may offer enhanced integration with digital platforms for monitoring production lines in real time, predictive maintenance capabilities, and better energy efficiency. Manufacturers investing in such technologies are likely to gain a competitive edge, catering to both traditional and emerging markets.

Conclusion

The corrugated roof sheet making machine has revolutionized the way roofing materials are manufactured. As the industry continues to evolve, businesses that harness the latest technologies and adopt sustainable practices will likely thrive. In this dynamic market, the significance of high-quality, efficient production processes cannot be overstated. By staying at the forefront of innovation, corrugated roof sheet making machine companies will not only meet current demands but also pave the way for future advancements in the construction and manufacturing industries.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025