Top Manufacturers of Angle Roll Forming Machines for Precision Metal Fabrication

The Rise of Angle Roll Forming Machine Manufacturers

In the world of metal fabrication, efficiency and precision are paramount. As industries continue to evolve, the demand for high-quality and reliable equipment has led to a significant rise in the production and innovation of angle roll forming machines. These machines are pivotal in shaping metal into angles, which are essential components in various applications, including construction, automotive, and manufacturing. This article delves into the burgeoning landscape of angle roll forming machine manufacturers, exploring their significance, technological advancements, and the future of this essential equipment.

Understanding Angle Roll Forming Machines

Angle roll forming machines are specialized tools designed to bend and shape metal sheets and profiles into specific angles. These machines work by feeding metal through rollers that apply pressure, enabling precise bends without compromising the integrity of the material. Typically used for producing angles of steel, aluminum, and other metals, they play a crucial role in industries such as structural fabrication, where the demand for robust components is constant.

The Evolution of Manufacturing Techniques

Over the past decade, there has been a noticeable shift in manufacturing techniques. Traditional methods of bending and shaping metal have given way to more sophisticated and efficient processes driven by technological advancements. Modern angle roll forming machines are equipped with advanced features such as digital control systems, hydraulic controls, and CNC technology. These innovations enable higher precision, repeatability, and efficiency in production, significantly reducing waste and improving overall productivity.

Moreover, manufacturers are increasingly focusing on automation and integration with other processes. The advent of Industry 4.0 means that angle roll forming machines can now be connected to IoT devices for real-time monitoring and predictive maintenance. This not only enhances operation efficiency but also minimizes downtime, ensuring that manufacturing plants can run smoothly and effectively.

The Competitive Landscape

The increase in demand for angle roll forming machines has led to the emergence of numerous manufacturers globally. This competitive landscape includes both established companies and new entrants, all striving to capture market share through innovation and quality. Key players in this market often emphasize their engineering capabilities, offering custom solutions tailored to specific industry needs.

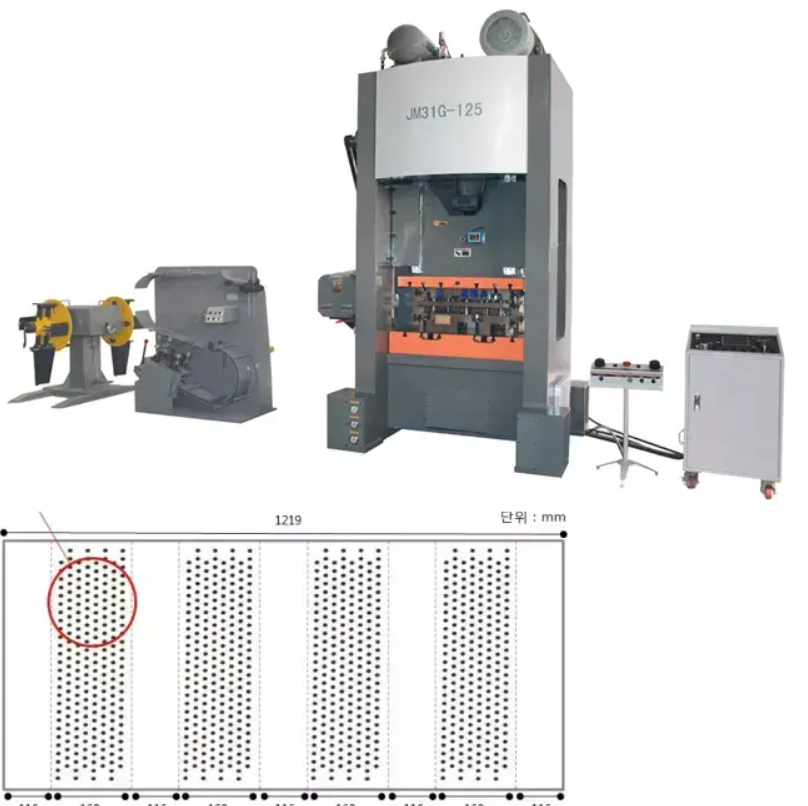

angle roll forming machine manufacturers

Quality and reliability remain critical factors for manufacturers. Customers seek machines that are not only durable and high-performing but also come with excellent after-sales service and support. This has led to the establishment of strong partnerships between manufacturers and customers, fostering an environment of trust and collaboration.

Sustainability and Environmental Considerations

As industries become more aware of their environmental impact, angle roll forming machine manufacturers are also adapting to these changes. More manufacturers are investing in eco-friendly technologies and practices. This includes developing machines that consume less energy and produce minimal waste, aligning with global sustainability goals.

Furthermore, the use of recyclable materials in the manufacturing process is becoming more common. This circular economy approach not only reduces the environmental footprint but also appeals to a growing base of environmentally conscious customers.

The Future of Angle Roll Forming Machines

Looking ahead, the future of angle roll forming machine manufacturers appears promising. As industries continue to innovate and demand for custom metal profiles rises, these manufacturers are well-positioned to meet the changing needs of the market. The integration of artificial intelligence and machine learning in production processes holds significant potential for enhancing efficiency and predicting customer needs more accurately.

Additionally, the ongoing quest for lightweight materials, especially in the automotive and aerospace sectors, will encourage further advancements in angle roll forming technology. Manufacturers that can adapt to the needs of these evolving industries will thrive in the market.

Conclusion

Angle roll forming machines are an integral part of modern manufacturing, and their manufacturers play a crucial role in driving innovation and quality. As technology advances, these manufacturers are poised to adapt and lead the way in producing efficient, reliable, and sustainable solutions. With a keen focus on customer needs, quality, and environmental sustainability, the future of angle roll forming machine manufacturers looks bright, ensuring that they remain at the forefront of metal fabrication for years to come.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025