Aluminum Roof Panel Production Line for Efficient Roll Forming Solutions

Aluminium Roof Panel Roll Forming Machine Revolutionizing the Construction Industry

In recent years, the construction industry has witnessed a significant transformation, primarily driven by advancements in manufacturing technologies. One such innovation making waves is the aluminium roof panel roll forming machine. This essential piece of equipment is transforming how roofing systems are designed, manufactured, and installed, offering distinct advantages over traditional methods.

The aluminium roof panel roll forming machine is designed to produce aluminium roofing panels that are not only lightweight but also durable and aesthetically pleasing. These machines utilize a continuous process that involves feeding a flat strip of aluminium through a series of rollers, which then shape the metal into desired profiles. This method ensures that the final product maintains uniform quality and dimensional accuracy while minimizing waste.

One of the standout features of an aluminium roof panel roll forming machine is its ability to cater to various design specifications. The versatility of these machines allows manufacturers to create panels in different thicknesses, lengths, and configurations, meeting the unique demands of each project. Whether it’s for residential homes, commercial buildings, or industrial facilities, these machines can produce roofing solutions that suit a wide range of architectural styles.

The use of aluminium as a primary material for roofing panels offers numerous benefits. Aluminium is highly resistant to corrosion, making it ideal for a variety of weather conditions. Unlike traditional roofing materials that may decay or require frequent maintenance, aluminium panels retain their integrity and appearance over time. This durability translates to lower long-term costs for both builders and homeowners, as the need for repairs and replacements is significantly diminished.

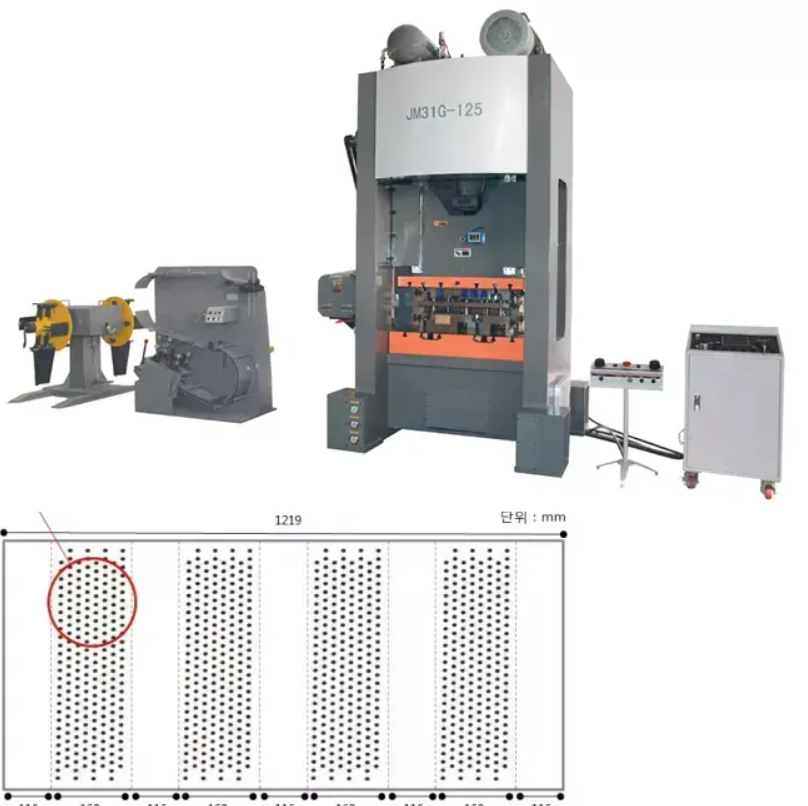

aluminium roof panel roll forming machine

Moreover, aluminium is an environmentally friendly material. It is 100% recyclable, which means that at the end of its life cycle, it can be repurposed without losing its properties. As the construction industry increasingly emphasizes sustainability, the use of recyclable materials like aluminium aligns with global efforts to promote eco-friendly practices. The operational efficiency of the roll forming process also contributes to sustainability, as it minimizes waste and energy consumption compared to traditional manufacturing methods.

Another significant advantage of the aluminium roof panel roll forming machine is its efficiency in production. The automated nature of these machines allows for rapid processing, reducing lead times and enabling manufacturers to meet tight project deadlines. Additionally, the precision engineering involved in the roll forming process ensures that panels are produced to exact specifications, which facilitates seamless installation and enhances the overall quality of construction projects.

Furthermore, manufacturers can easily integrate modern technology into these machines. Features such as computer numerical control (CNC) systems allow for enhanced customization and real-time monitoring of the production process. This technological integration not only boosts productivity but also improves the accuracy and consistency of the final product.

In conclusion, the aluminium roof panel roll forming machine represents a significant advancement in the construction industry. By offering lightweight, durable, and sustainable roofing solutions, these machines facilitate more efficient production methods while meeting the diverse needs of modern architecture. As builders and homeowners increasingly seek innovative materials and processes, the role of aluminium roof panel roll forming machines will undoubtedly continue to grow, paving the way for a more robust and eco-friendly construction sector. With these machines at the forefront, the future of roofing looks brighter and more efficient than ever before.

-

Corrugated Iron Roofing Sheet Making Machine: Fast, Precise & DurableNewsAug.29, 2025

-

Q Tile Metal Roofing Step Tile Forming Machine | Efficient & DurableNewsAug.28, 2025

-

The Role of Hydraulic Systems in Sheet Metal SlittersNewsAug.23, 2025

-

Customization Options in Metal Deck Roll Forming MachinesNewsAug.23, 2025

-

Safety Tips When Using a Gutter Making MachineNewsAug.23, 2025

-

Key Components of a C Purlin Machine ExplainedNewsAug.23, 2025

-

Maintenance Tips for a Steel Angle Roll Forming MachineNewsAug.23, 2025