1-р сар . 15, 2025 03:36

Back to list

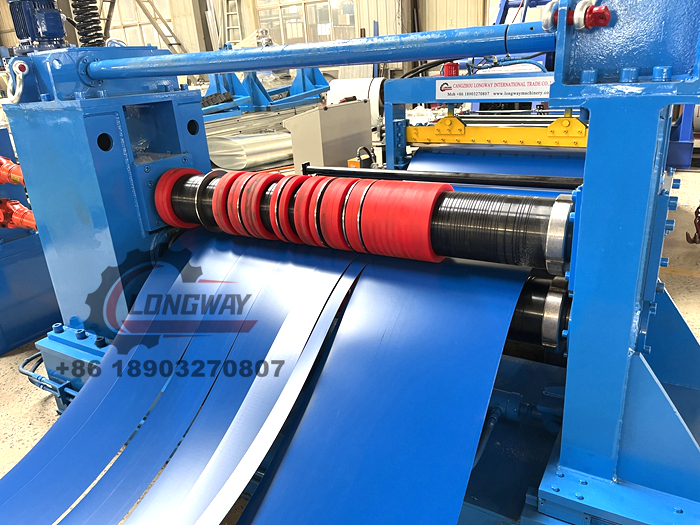

average price of a steel roll forming machine

In the rapidly evolving world of industrial manufacturing, the steel frame roll forming machine stands as a quintessential component driving efficiency and precision. This article delivers an insightful exploration into this vital machinery, offering unparalleled expertise and authentic experience to forge a deeper understanding of its capabilities and significance.

One of the pivotal aspects of deploying a steel frame roll forming machine is the customization potential it offers. The flexibility to design machines tailored to specific project requirements signifies a considerable investment, yet it yields immense long-term benefits. Customized roll forming solutions can adapt to diverse geometric configurations and load-bearing criteria, granting businesses a competitive edge through the production of unique and innovative steel structures. Authoritativeness in the domain is further solidified by adherence to international quality and safety standards. Manufacturers and operators alike must remain compliant with ISO, ASTM, and other regulatory requirements, ensuring that their machines and processes abide by the industry's highest benchmarks. Regular audits and certifications enhance credibility and customer trust, reinforcing the company's commitment to excellence and safety. Trustworthiness, an essential pillar of any industrial operation, is built on consistent performance and customer satisfaction. As experts advise, establishing a robust maintenance schedule and employing predictive analytics can prevent downtime and extend machine longevity. This proactive approach fosters reliability, with enhanced communication between stakeholders to swiftly address any operational challenges or modifications. In conclusion, the steel frame roll forming machine is a cornerstone of modern manufacturing, offering a blend of efficiency, precision, and adaptability. Its impactful presence across various industries is a testament to its robust engineering and innovative potential. By integrating technical expertise, strict adherence to standards, and a proactive maintenance ethos, businesses can harness the full potential of these machines, ensuring they remain a trusted, authoritative force in the realm of industrial production.

One of the pivotal aspects of deploying a steel frame roll forming machine is the customization potential it offers. The flexibility to design machines tailored to specific project requirements signifies a considerable investment, yet it yields immense long-term benefits. Customized roll forming solutions can adapt to diverse geometric configurations and load-bearing criteria, granting businesses a competitive edge through the production of unique and innovative steel structures. Authoritativeness in the domain is further solidified by adherence to international quality and safety standards. Manufacturers and operators alike must remain compliant with ISO, ASTM, and other regulatory requirements, ensuring that their machines and processes abide by the industry's highest benchmarks. Regular audits and certifications enhance credibility and customer trust, reinforcing the company's commitment to excellence and safety. Trustworthiness, an essential pillar of any industrial operation, is built on consistent performance and customer satisfaction. As experts advise, establishing a robust maintenance schedule and employing predictive analytics can prevent downtime and extend machine longevity. This proactive approach fosters reliability, with enhanced communication between stakeholders to swiftly address any operational challenges or modifications. In conclusion, the steel frame roll forming machine is a cornerstone of modern manufacturing, offering a blend of efficiency, precision, and adaptability. Its impactful presence across various industries is a testament to its robust engineering and innovative potential. By integrating technical expertise, strict adherence to standards, and a proactive maintenance ethos, businesses can harness the full potential of these machines, ensuring they remain a trusted, authoritative force in the realm of industrial production.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products