roll forming machine for sheet metal

Roll Forming Machine for Sheet Metal A Comprehensive Overview

In the world of manufacturing and fabrication, the roll forming machine for sheet metal has emerged as an indispensable tool. This process involves the continuous bending of sheet metal into desired cross-sectional shapes, using a series of progressively arranged rolls. With its efficiency, precision, and versatility, roll forming has revolutionized the way metal components are produced across various industries, including construction, automotive, and appliance manufacturing.

Understanding the Roll Forming Process

Roll forming is a cold metal forming process that transforms flat sheet metal into rolled sections or profiles. The process begins with a flat strip of metal being fed through a series of rollers, each designed to bend the metal incrementally. The design of the roll forming machine allows for a continuous operation, with the metal strip being shaped without interruption.

The process typically involves a preliminary setup where the desired profile is designed using software. This can include a wide array of shapes, such as angles, channels, and custom contours. Precision is paramount in this stage, as the accuracy of the initial design will directly affect the final product.

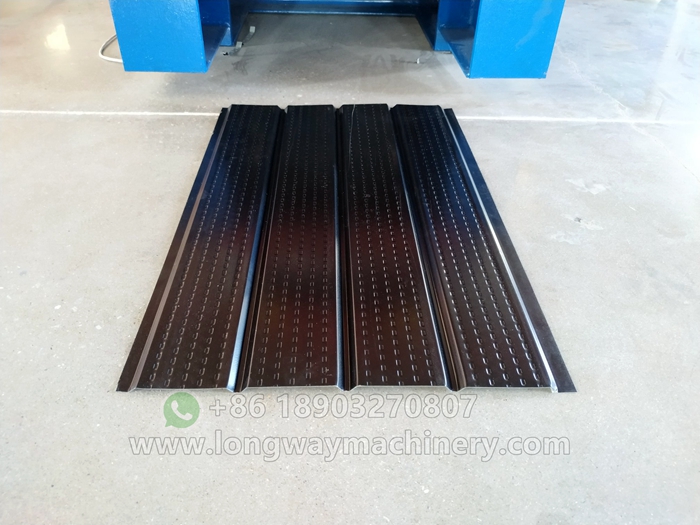

Once the design is ready, the sheet metal is fed into the machine. The rollers, positioned in a specific sequence, gradually bend the metal according to the pre-set design. The final output is a long piece of metal profile that can be cut to size based on the specific requirements of the job.

Advantages of Roll Forming Machines

1. High Efficiency One of the most significant benefits of roll forming machines is their ability to produce large quantities of metal profiles quickly. The continuous nature of the process minimizes downtime and enhances productivity.

2. Material Utilization Roll forming is known for its efficient use of materials. Unlike traditional machining methods that often result in considerable waste, roll forming utilizes the entire sheet, maximizing output while minimizing scrap.

3. Precision and Consistency Roll forming machines are designed to produce high-tolerance parts with consistent dimensions. This is crucial for industries where components must fit together seamlessly.

roll forming machine for sheet metal

4. Versatility Roll forming can produce a diverse range of profiles, from simple shapes to complex designs. This versatility allows manufacturers to meet various application requirements without needing multiple machines.

5. Cost-Effectiveness Although the initial setup cost for a roll forming line may be substantial, the long-term savings in material waste, labor costs, and production time make it a cost-effective solution for many manufacturers.

Applications of Roll Forming Machines

Roll forming machines are used in multiple industries, each benefiting from their unique capabilities. In the construction sector, they are essential for producing roofing sheets, wall panels, and structural components. Automotive industries rely on roll forming for creating parts like door frames, bumpers, and chassis components, where precision and durability are critical.

Additionally, the appliance industry utilizes roll forming for various applications, including the production of brackets, racks, and other structural elements in household and industrial equipment. The ability to design custom profiles enables manufacturers to tailor solutions to specific needs, further solidifying the significance of roll forming machines in modern manufacturing.

Future Trends in Roll Forming

The roll forming industry is continually evolving, with advancements in technology driving innovations. Automation and integration of computer numerical control (CNC) systems are becoming standard, enhancing precision and reducing the labor required for machine operation. Furthermore, the incorporation of smart technology and Industry 4.0 principles is enabling real-time monitoring and predictive maintenance, which helps in minimizing downtime and optimizing production processes.

Moreover, as industries push for more sustainable practices, roll forming machines are being adapted to work with eco-friendly materials, including recycled metals. This aligns with global efforts to reduce the carbon footprint and promote sustainable manufacturing practices.

Conclusion

The roll forming machine for sheet metal is a cornerstone of modern metal fabrication. Its efficiency, precision, and versatility make it a preferred choice across various industries. As technology continues to advance, the roll forming process will likely see further enhancements, solidifying its role in the future of manufacturing. With the potential for customization and broad applications, roll forming machines will remain a crucial asset for manufacturers aiming to meet the demands of an ever-evolving market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025