roll former for volcometal parante factory

The Role of Roll Formers in Volcometal Parante Factory Production

In the ever-evolving landscape of manufacturing, the efficiency and effectiveness of production processes are crucial for the success of any business. At the forefront of innovative manufacturing solutions is the roll former, a piece of machinery that has significantly transformed operations in various industries, including that of the Volcometal Parante Factory. This article sheds light on the importance of roll forming technology in the production processes at Volcometal Parante, illustrating how it enhances productivity, ensures quality, and fosters sustainability.

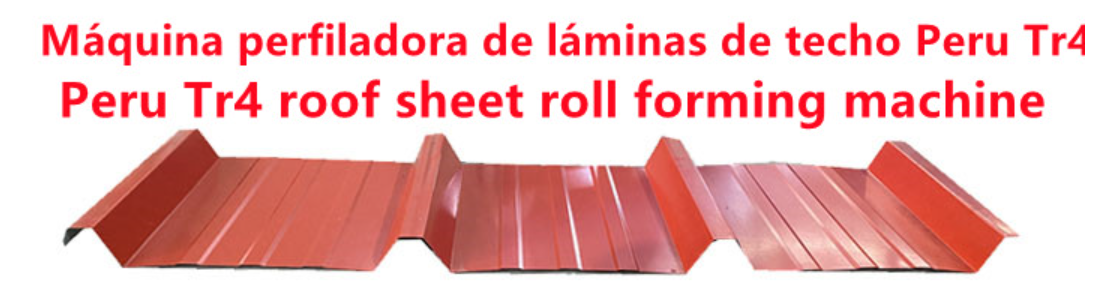

Roll forming is a continuous bending operation in which a long strip of metal, often coiled steel, is passed through consecutively arranged sets of rollers to create a desired cross-section. This method is particularly effective for producing complex shapes and lengths that are often required in the manufacturing of metal components. At Volcometal Parante Factory, the roll former is indispensable for producing components used in construction, automotive, and various other sectors.

One of the primary advantages of utilizing roll forming at Volcometal Parante is the high degree of precision it offers. The machinery is designed to create consistent shapes with minimal tolerance variations. This precision is vital in ensuring that components fit together seamlessly, thus reducing the likelihood of manufacturing defects that could lead to costly reworks or customer dissatisfaction. This is particularly important in industries where safety and structural integrity are paramount.

roll former for volcometal parante factory

Moreover, the roll forming process is notably efficient. Unlike other metal fabrication methods, roll forming can produce long lengths of product in a single pass, significantly speeding up production times. This operational efficiency allows Volcometal Parante to meet tight deadlines and respond swiftly to market demands. As a result, the factory can maintain a competitive edge, delivering high-quality products in a timely manner.

In addition to efficiency and precision, sustainability is becoming increasingly important in manufacturing. The roll forming process generates minimal waste compared to other methods, such as stamping or machining, where excess materials often end up as scrap. At Volcometal Parante, efforts to reduce waste are part of a broader commitment to sustainable manufacturing practices. The factory strives to optimize material usage, recycling scrap to create new products, thereby minimizing its environmental footprint.

Furthermore, the versatility of roll forming allows Volcometal Parante to diversify its product offerings. The machinery can be easily adjusted to produce various shapes and sizes, catering to the specific needs of different industries. This flexibility enables the factory to tap into new markets and respond to changing consumer preferences more effectively.

In conclusion, the integration of roll forming technology at Volcometal Parante Factory exemplifies the transformative power of modern manufacturing techniques. By enhancing precision, improving efficiency, fostering sustainability, and offering versatility in production, roll forming plays a pivotal role in the factory's operations. As the manufacturing landscape continues to evolve, embracing such innovative solutions will be essential for staying competitive and meeting the demands of an increasingly dynamic market. The future looks bright for Volcometal Parante as it continues to harness the power of technology to drive success.

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025

-

The Essential Guide to Floor Deck Roll Forming MachinesNewsMay.16, 2025

-

Slitting Lines and Their BenefitsNewsMay.16, 2025

-

Sheet Metal Slitting Machines and Their OptionsNewsMay.16, 2025

-

Choosing the Best Downpipe Roll Forming MachinesNewsMay.16, 2025

-

5 Inch Gutter Machines: The Key to Efficient Gutter ProductionNewsMay.16, 2025

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025