metal roof rolling machines

The Advantages of Metal Roof Rolling Machines

In recent years, the construction industry has witnessed a significant shift towards the use of metal roofing systems. These systems are not only cost-effective but also durable and aesthetically pleasing. A pivotal piece of equipment that enables the efficient production of metal roofing sheets is the metal roof rolling machine. This piece of machinery plays a vital role in the manufacturing process, allowing for the creation of high-quality roofing materials that meet the demands of modern architectural designs.

What is a Metal Roof Rolling Machine?

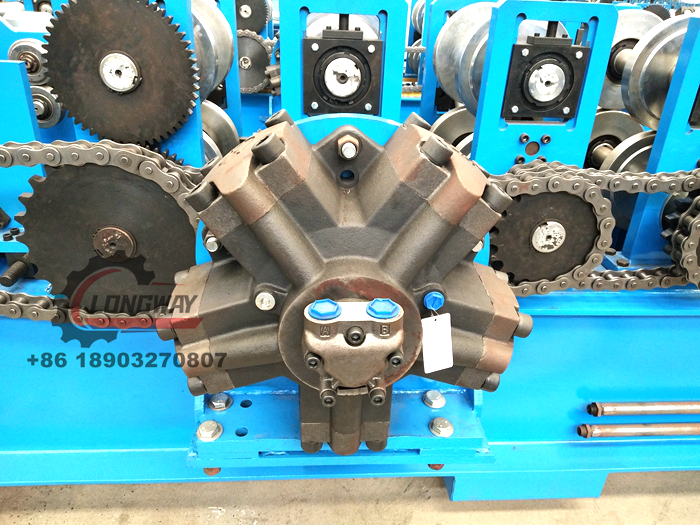

A metal roof rolling machine is a specialized piece of equipment designed to cold-form metal sheets into various profiles used for roofing. These machines can produce a variety of shapes, including standing seam roofs, corrugated sheets, and tile-like profiles. The operation of a metal roof rolling machine typically involves the feeding of flat metal sheets, which are then shaped and cut into the desired lengths and profiles.

Efficiency in Production

One of the primary advantages of employing metal roof rolling machines is the efficiency they bring to the manufacturing process. Unlike traditional metal cutting and shaping methods, rolling machines can produce roofing materials at a faster rate with minimal waste. This efficiency not only enhances productivity but also reduces costs associated with material waste and labor.

Additionally, these machines can operate with a high degree of automation. Modern metal roof rolling machines often come equipped with computerized control systems that allow operators to program different profiles and dimensions. This feature significantly streamlines the production process, enabling manufacturers to switch from one design to another without extensive manual intervention.

High-Quality Outputs

The precision offered by metal roof rolling machines ensures that each roofing panel is made to exact specifications. Consistent quality is crucial in the roofing industry, where discrepancies can lead to significant structural problems. The rollers in these machines are designed to maintain consistent pressure and alignment, resulting in uniform thickness and profiles that are crucial for proper installation.

metal roof rolling machines

Moreover, the ability to adjust the roll forming process allows manufacturers to experiment with different metal types and coatings, further enhancing the durability and aesthetic appeal of the roofing products. As a result, builders have access to a wider range of materials that can cater to specific environmental conditions and architectural styles.

Versatility of Design

Metal roof rolling machines offer unparalleled versatility in design options. With the ability to create various profiles, manufacturers can produce roofing systems that not only serve functional purposes but also complement the overall design of a building. From sleek modern structures to traditional designs, the versatility in the shapes and finishes of metal roofing systems can meet diverse architectural demands.

Additionally, manufacturers can easily adapt the machines to produce customized profiles based on client specifications. This adaptability is particularly important in a competitive construction market, where unique designs can give one builder a distinct edge over another.

Environmental Considerations

In an age where sustainability is a pressing concern, metal roofing systems are often viewed as an eco-friendly option. Metal roofs reflect solar heat, contributing to energy efficiency in buildings. Moreover, roofing systems created with metal roof rolling machines can be made from recycled materials, and the lifespan of metal roofs often outlasts traditional roofing options, reducing the need for frequent replacements.

The minimal waste generated during the manufacturing process, combined with the durability of the final product, positions metal roofing as a sustainable choice that benefits both builders and the environment.

Conclusion

In conclusion, metal roof rolling machines are essential tools in the modern construction industry, offering advantages that include improved efficiency, high-quality outputs, versatility in design, and environmental benefits. As the demand for metal roofing continues to grow, the importance of these machines will only increase. By leveraging advanced technology in the creation of metal roofing systems, manufacturers can ensure they meet the evolving needs and standards of the industry while contributing positively to sustainability efforts.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025