metal deck roll forming machine factories

The Rise of Metal Deck Roll Forming Machine Factories

In recent years, the construction industry has witnessed a significant shift towards the adoption of metal decking solutions. This surge in demand has given rise to a proliferation of metal deck roll forming machine factories. These specialized manufacturing facilities are equipped to produce high-quality metal decking products that meet the diverse needs of the construction sector.

Understanding Metal Decking

Metal decking is a pre-engineered, light-gauge galvanized steel product commonly used in commercial and industrial construction. Its primary function is to act as a structural component in floors and roofs, providing support for concrete slabs in composite floor systems. The lightweight yet robust nature of metal decking makes it an ideal choice for both new construction and renovation projects.

There's a wide variety of metal decking, including roof deck, composite deck, and form deck, each designed for specific applications. As demand for faster, more efficient construction methods grows, the need for high-quality metal decking solutions becomes increasingly important.

The Role of Roll Forming Machines

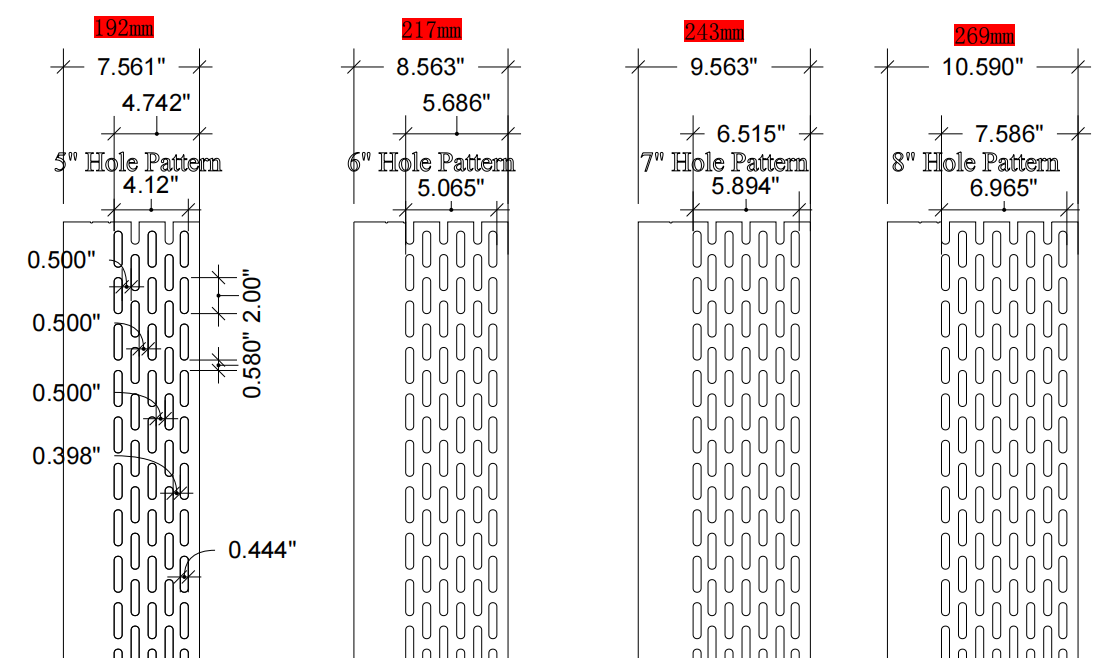

Roll forming is a continuous bending operation in which a long strip of metal is passed through a series of rollers that gradually shape it into the desired profile. Metal deck roll forming machines are designed to create specific decking profiles with precision and efficiency. The machines operate by feeding coils of metal into the system, where they are formed into the required shape through a series of successive rollers.

One of the key benefits of using roll forming technology in metal decking production is the ability to maintain consistency and accuracy across large volumes of product. With advancements in automation and precision engineering, modern roll forming machines can produce decking profiles at a remarkable speed while reducing waste.

Why Factories Specializing in Metal Deck Roll Forming Are Emerging

1. Increased Construction Activity As economies around the world grow, more construction projects are initiated. This growth translates to a higher demand for reliable, cost-effective metal decking solutions. Consequently, the need for factories producing roll forming machines increases.

metal deck roll forming machine factories

2. Technological Advancements Innovations in manufacturing processes have made it more feasible to set up specialized factories. Modern metal deck roll forming machines are equipped with cutting-edge technology that enhances efficiency, reduces production time, and improves product quality.

3. Customization Today's construction projects often demand bespoke solutions tailored to specific requirements. Factories focusing on metal deck roll forming can offer custom profiles and dimensions, catering to the unique needs of clients.

4. Sustainability Metal decking is often preferred for its recyclability and environmentally friendly attributes. As construction practices evolve towards sustainability, the production of metal decking through state-of-the-art roll forming techniques aligns well with eco-friendly initiatives.

Key Considerations for Metal Deck Roll Forming Machine Factories

1. Quality Control Ensuring consistent quality in finished products is crucial. Factories must invest in robust quality control systems to monitor the entire production process, from raw material selection to final inspections.

2. Training and Expertise Skilled personnel are essential to operate and maintain advanced machinery. Factories should prioritize employee training programs to keep workers updated on the latest production techniques and safety practices.

3. Market Trends Continual assessment of market demands and industry trends is vital for staying competitive. Factories should regularly evaluate their product offerings to align with evolving client needs.

4. Client Collaboration Building strong relationships with clients can lead to better understanding of their requirements. Engaging directly with customers allows factories to adapt their production capabilities effectively.

Conclusion

The rise of metal deck roll forming machine factories signifies a positive development in the construction industry. These facilities not only provide essential materials but also drive innovation and efficiency in building practices. As the demand for high-quality metal decking continues to grow, so too will the importance of specialized factories dedicated to this vital aspect of modern construction. With the right investments in technology and workforce development, these factories will be well-positioned to meet the challenges of tomorrow’s construction landscape.