grain silo roll forming machine factories

The Evolution and Significance of Grain Silo Roll Forming Machines

In the realm of modern agriculture and farming infrastructure, grain storage is crucial for maintaining the quality and safety of harvested products. As the global demand for food rises, the efficiency of grain storage systems must keep pace. One of the most innovative solutions in this context is the roll forming machine, specifically designed for the construction of grain silos. This article explores the technology behind grain silo roll forming machines, their manufacturing process, and their significance in the agricultural industry.

Understanding Roll Forming Technology

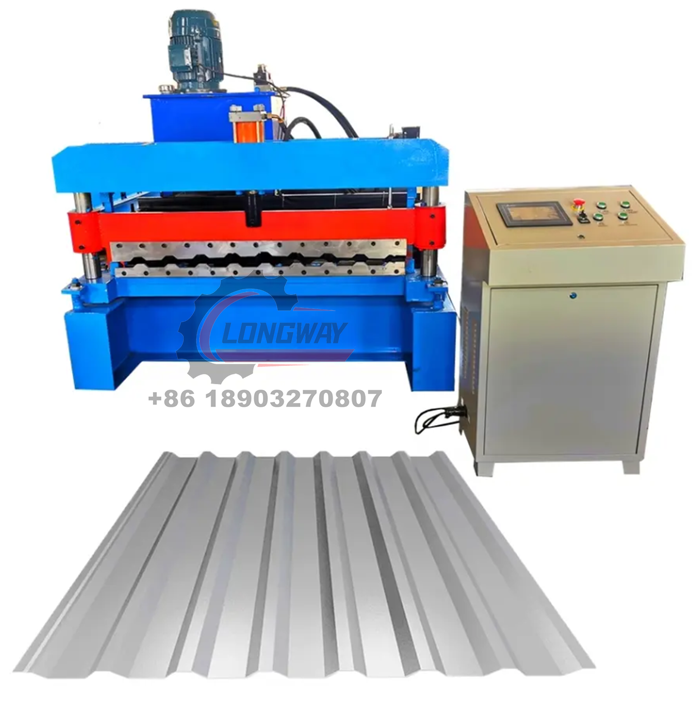

Roll forming is a continuous manufacturing process that involves feeding a strip of metal into a series of rollers. These rollers gradually shape the metal into a predetermined profile. This technique is not only efficient but also allows for the mass production of components with high consistency and precision. Grain silo roll forming machines have been specially designed to produce the corrugated sheets used in the construction of silos, which are essential for storing grain, seeds, and other agricultural products.

The Manufacturing Process

The manufacturing of grain silos typically starts with the selection of high-quality steel, which is known for its durability and resistance to environmental factors. Once the raw material is selected, it is fed into the roll forming machine. The machine consists of a series of rollers, each performing a specific part of the shaping process. As the steel passes through the rollers, it is gradually formed into corrugated panels, which have several advantages, including increased strength and efficient stacking ability.

Once the panels are formed, they can be cut to the desired lengths and then transported to the construction site. This process not only speeds up silo production but also minimizes material wastage, making it a cost-effective solution for farmers and agricultural businesses.

Advantages of Using Roll Formed Silos

1. Durability and Longevity Roll formed silos are constructed with high-quality steel, ensuring that they can withstand harsh weather conditions, such as rain, snow, and high winds. This resilience translates into a longer lifespan and reduced maintenance costs.

grain silo roll forming machine factories

2. Customization The roll forming process allows for significant customization of the silo dimensions and design. Depending on specific storage needs, manufacturers can produce silos of varying heights and diameters without extensive retooling.

3. Cost Efficiency The mass production capabilities of roll forming not only reduce labor costs but also lower material costs due to minimized scrap. This efficiency propagates throughout the agricultural supply chain, making it a more viable solution for farmers.

4. Quick Installation With pre-formed, standardized panels, the erection of the silos can be accomplished swiftly. This rapid installation is essential for farmers who need to protect their grains promptly, especially during harvest season.

5. Environmental Considerations Many modern roll forming machines are designed to adhere to sustainable practices. This can include recycling scrap metal and utilizing energy-efficient production methods, which align with the growing trend of eco-friendly farming.

Market Trends and Future Outlook

As the agriculture sector continues to evolve, the demand for robust storage solutions is expected to grow. The rise in population and subsequent food demand will further drive the need for effective grain storage solutions. Grain silo roll forming machine factories are thus likely to see a surge in demand as farmers and agricultural businesses seek to enhance their storage capabilities.

Moreover, technological advancements in roll forming techniques, such as automation and digital manufacturing, are poised to revolutionize the grain storage industry. These innovations promise to increase production efficiency and improve product quality, making roll forming machines more attractive investments for businesses involved in agricultural storage solutions.

Conclusion

Grain silo roll forming machines represent a significant advancement in agricultural technology, contributing to the effective and efficient storage of grains. The advantages they offer in terms of durability, customization, and cost-effectiveness are crucial for modern farmers facing increasing demands. As the agricultural landscape evolves, it is clear that these machines will play a vital role in ensuring that the world’s food supply is stored safely and sustainably. The future of grain storage undoubtedly looks promising with the continued development and implementation of roll forming technology.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025