galvanized sheet roll forming machine

The Importance of Galvanized Sheet Roll Forming Machines in Modern Manufacturing

In today's fast-paced manufacturing landscape, the demand for durable, high-quality materials is ever-increasing. One of the standout solutions for producing such materials is the galvanized sheet roll forming machine. This advanced technology plays a crucial role in shaping and reinforcing metal sheets for a variety of applications, from construction to automotive industries.

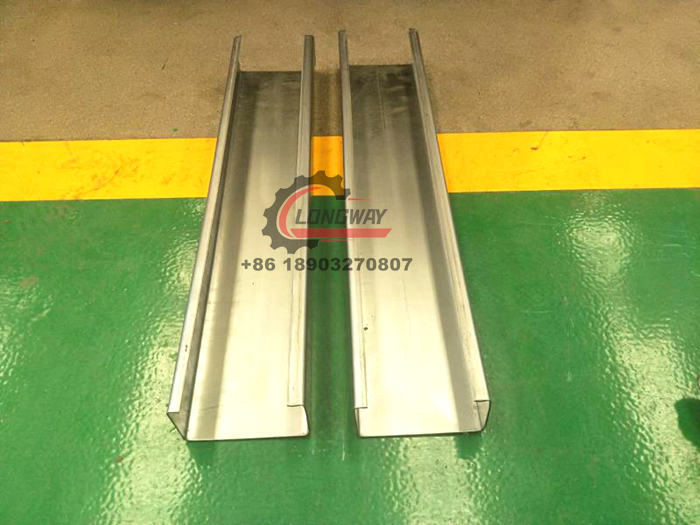

At its core, a galvanized sheet roll forming machine is designed to continuously form metal sheets into desired profiles. The process begins with a flat galvanized steel coil, which is fed into the machine. Through a series of rollers, the steel is gradually shaped and formed into specified profiles, including roofing sheets, wall panels, and other structural components. The galvanization process involves coating the steel with a layer of zinc, providing excellent corrosion resistance. This feature is particularly beneficial for applications exposed to harsh environmental conditions.

One of the significant advantages of using galvanized sheet roll forming machines is efficiency. Traditional methods of metal fabrication can be time-consuming and labor-intensive. However, these machines can produce complex shapes with high precision and at a much faster rate. This efficiency not only reduces production time but also lowers labor costs, making it an economically viable option for manufacturers.

galvanized sheet roll forming machine

Moreover, the versatility of galvanized sheet roll forming machines cannot be overstated. They can be tailored to create various profiles and thicknesses, accommodating the specific needs of different projects. Whether it’s panels for agricultural buildings or roofing for residential homes, these machines can easily adapt to meet diverse requirements.

Sustainability is another driving force behind the use of galvanized sheet roll forming machines. By using galvanized steel, manufacturers contribute to environmental conservation efforts. The longevity and durability of galvanized materials mean less frequent replacements, thus reducing waste. Additionally, steel, being recyclable, presents an opportunity for continuous reuse and repurposing, aligning with modern sustainability practices.

In summary, galvanized sheet roll forming machines are indispensable in the contemporary manufacturing scene. They combine efficiency, versatility, and sustainability, making them a preferred choice for producing high-quality metal components. As industries continue to evolve, the role of these machines in meeting the demands for durable, cost-effective materials will only grow, underscoring their relevance in the future of manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025