High-Quality Downspout Pipe Roll Forming Machine Manufacturer

The Evolution and Importance of Downspout Pipe Roll Forming Machines in Modern Manufacturing

In the landscape of modern manufacturing, the significance of specialized machinery cannot be overstated. One such innovation that has gained prominence is the downspout pipe roll forming machine. This advanced equipment plays a critical role in the production of downspouts—essential components for effective rainwater management in both residential and commercial buildings.

A downspout is a vertical pipe that directs rainwater from roof gutters down to the ground or drainage system. The need for efficient water drainage systems has led to an increased demand for high-quality downspouts, making the roll forming process essential in the production line. The roll forming technique utilizes continuous bending of metal sheets to shape them into desired profiles, offering a range of benefits including precision, speed, and cost-effectiveness.

One of the key advantages of using a downspout pipe roll forming machine is the efficiency of the manufacturing process. These machines are designed to operate continuously, allowing for high-volume production with minimal downtime. Unlike traditional manufacturing methods that may require numerous hands-on procedures, roll forming streamlines the process, reducing labor costs and increasing productivity. This efficiency is crucial in meeting the rising consumer demand for downspouts and other metal profiles.

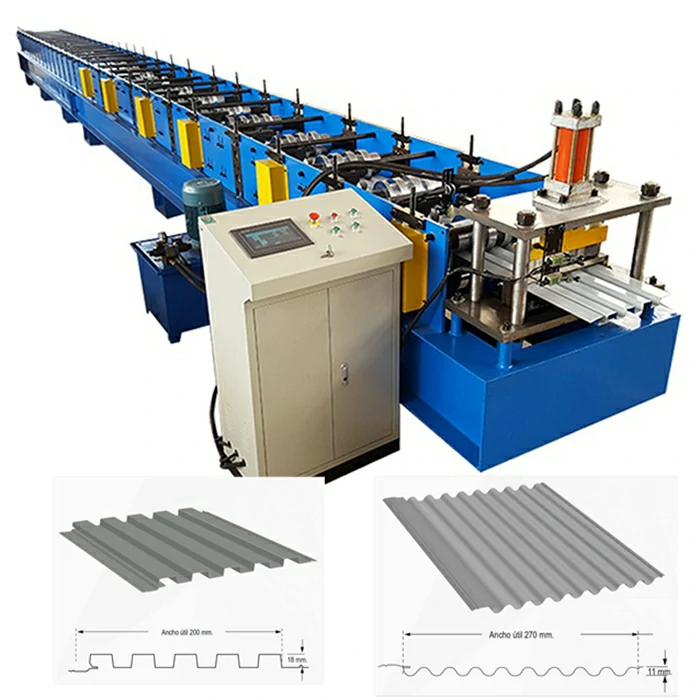

downspout pipe roll forming machine factory

Moreover, the versatility of roll forming machines is noteworthy. They can produce various downspout shapes and sizes according to specific requirements, which is valuable for contractors who work on diverse projects. Manufacturers can easily adjust settings to create custom profiles, making these machines indispensable in both large-scale industrial applications and smaller, bespoke projects. This adaptability not only enhances creativity in design but also optimizes resources, allowing firms to cater to a broader market.

Quality control is another significant factor in the production of downspout pipes. Roll forming machines ensure uniformity and consistency in the final product, which is essential for maintaining the structural integrity of downspouts. The durability of the downspout is vital, given its exposure to various weather conditions. Machines equipped with advanced technologies can monitor the forming process, detect any anomalies, and ensure that each downspout meets industry standards.

Investment in downspout pipe roll forming machines is not merely about enhancing production capabilities; it is also about sustainability. Modern machines are engineered to minimize waste, utilizing advanced cutting techniques and material handling systems. As sustainability becomes increasingly important in manufacturing, the adoption of energy-efficient and eco-friendly practices through the use of roll forming technology aligns perfectly with industry trends.

In conclusion, the downspout pipe roll forming machine represents a crucial evolution in modern manufacturing. Its efficiency, versatility, and contribution to quality control make it an essential tool for manufacturers looking to meet the demands of a competitive market. As the construction industry continues to grow, the importance of reliable drainage systems will only increase, solidifying the role of roll forming machines in the future. Embracing this technology will not only ensure the production of high-quality downspouts but also promote sustainability and innovation in the manufacturing sector.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025