Top Decoiler Manufacturers for Efficient Metal Processing Solutions

Decoiler Manufacturers An Essential Component in Metal Processing

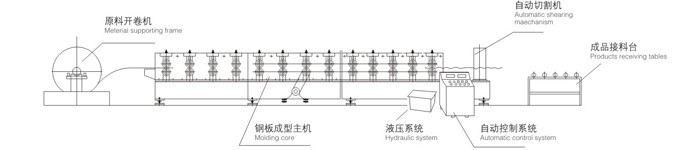

In the world of metal processing, the role of decoiler manufacturers cannot be understated. Decoilers are vital machinery used primarily in the handling and processing of rolled metal sheets and coils. Their function is to unwind metal coils, allowing for easier feeding into machining processes such as cutting, shaping, or bending. As industries increasingly rely on high-efficiency manufacturing systems, the demand for high-quality decoilers continues to rise.

Understanding Decoilers

Decoilers come in a variety of designs, each tailored to specific needs and applications. Typically, a decoiler consists of a rotating spindle that holds the coil, a mechanism for controlling the unwinding speed, and adjustable arms for guiding the metal sheet. There are manual, semi-automatic, and fully automatic decoilers, with automation features becoming increasingly common in modern manufacturing settings.

The choice of decoiler can significantly impact production efficiency. A well-designed decoiler minimizes the risks of coil damage, reduces downtime, and ensures a smooth flow of material feeding into subsequent processing stages. Therefore, businesses must carefully consider their decoiler manufacturers to ensure they select a reliable supplier that meets their specific operational demands.

Key Features of High-Quality Decoiler Manufacturers

1. Customization Options A reputable decoiler manufacturer will understand that not all businesses have the same needs. They should offer customizable solutions, like adjustable coil width, varying capacities to accommodate different coil sizes, and additional features that enhance performance.

2. Robust Construction The durability and longevity of decoiler equipment are crucial. A high-quality decoiler should be constructed from durable materials that can withstand the stress of continuous operation. This not only ensures a longer lifespan but also minimizes maintenance costs in the long run.

decoiler manufacturers

3. Innovative Technology The best decoiler manufacturers incorporate cutting-edge technology to enhance their products. This includes features such as automatic tension control, speed adjustments based on the thickness of the material, and integration with existing automated production lines for seamless operation.

4. Expert Support and Service An excellent decoiler manufacturer doesn’t just sell machinery; they provide comprehensive support and service. This includes installation services, training for operators, and ongoing maintenance support to ensure that the decoiler functions optimally throughout its lifecycle.

Market Trends in Decoilers

The global market for decoiler systems is growing, driven by advancements in the metalworking sector and the increasing need for efficiency in production lines. Industries such as automotive, aerospace, and manufacturing are all witnessing a shift toward automated processes, leading to heightened demand for sophisticated decoiler solutions.

Additionally, eco-friendly practices are on the rise, and decoiler manufacturers are responding by designing machines that prioritize energy efficiency and waste reduction. These innovations not only align with sustainable practices but also appeal to businesses aiming to improve their environmental footprint.

Conclusion

Decoiler manufacturers play a crucial role in the efficiency and effectiveness of metal processing operations. By selecting the right decoiler, businesses can enhance their production processes, reduce waste, and achieve better overall performance. As the market evolves, manufacturers that prioritize innovation, customization, and customer support are likely to lead in this dynamic industry. As businesses continue to seek competitive advantages, partnering with a reliable decoiler manufacturer will prove essential in meeting their operational goals.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025