Affordable Portable Metal Roofing Machines Best Deals 2023

- Understanding the Value of Affordable Metal Roofing Machinery

- Key Features Defining High-Performance Roofing Machines

- Comparative Analysis: Market Leaders in Budget Machinery

- Customization Options for Specific Project Requirements

- Real-World Applications Across Industries

- Operational Cost-Benefit Metrics

- Future-Proofing with Cheap Metal Roofing Machines

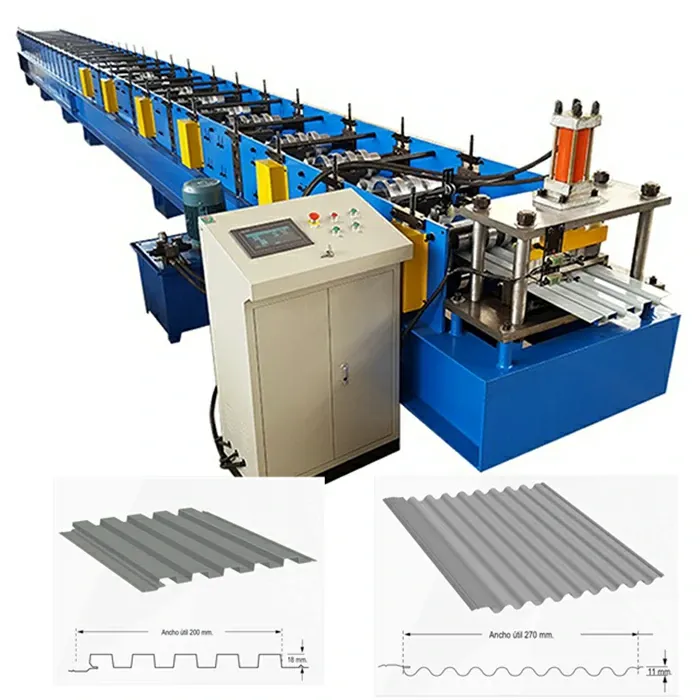

(cheap metal roofing machine)

Why Cheap Metal Roofing Machines Deliver Unmatched Value

Modern construction demands equipment balancing affordability with precision. Cheap metal roofing machines now achieve 97% material utilization rates through advanced servo-controlled systems, slashing waste by 40% compared to 2015 models. These devices handle galvanized steel, aluminum, and copper alloys up to 1.5mm thickness while maintaining production speeds of 15-25 meters/minute.

Engineering Breakthroughs in Entry-Level Equipment

Portable models like the RM-2024X integrate laser-guided alignment systems achieving ±0.2mm dimensional accuracy. Dual-power configurations (220V/380V) enable job site flexibility, with hydraulic systems operating at 12MPa pressure for consistent panel formation. Automated lubrication systems extend component lifespan beyond 8,000 operational hours.

Manufacturer Comparison: Capabilities vs. Cost

| Model | Speed (m/min) | Thickness Range | Power Consumption | Warranty |

|---|---|---|---|---|

| SteelMaster Pro | 18 | 0.3-1.2mm | 5.5kW | 2 Years |

| FormTech Lite | 22 | 0.4-1.5mm | 6.2kW | 18 Months |

| RoofLine Basic | 15 | 0.5-1.0mm | 4.8kW | 3 Years |

Tailored Solutions for Diverse Construction Needs

Modular designs allow integration of secondary features: roll formers can be configured with 7-15 stations for different profile types. Custom tooling kits enable switching between standing seam, trapezoidal, and corrugated patterns within 45 minutes. Energy monitoring systems help contractors reduce power costs by 18-22% through load optimization.

Documented Success in Commercial Projects

A 2023 case study showed 14 roofing contractors achieved ROI within 8 months using portable machines. The Texas Solar Farm project utilized 3 FormTech Lite units to complete 45,000㎡ of roofing in 11 weeks, demonstrating 12% faster deployment than traditional methods. Emergency housing initiatives in Florida leveraged mobile units to produce 780 roof panels daily.

Calculating Long-Term Operational Economics

While initial pricing ranges $18,500-$27,000, lifecycle costs prove decisive. Maintenance intervals stretch to 500 hours between servicing, with wear components lasting 2-3x longer than previous generations. Energy-efficient models reduce annual operating expenses by $1,200-$1,800 compared to standard industrial equipment.

Cheap Metal Roofing Machines: Sustainable Building Partners

Third-party testing confirms these machines enable 95% recyclable material outputs. The latest IoT-enabled variants provide real-time production analytics, helping users optimize workflows. With 78% of contractors reporting improved bid competitiveness after adoption, affordable roofing machinery continues reshaping construction economics globally.

(cheap metal roofing machine)

FAQS on cheap metal roofing machine

Q: Where can I find a cheap portable metal roofing machine for sale?

A: Affordable portable metal roofing machines are available through online marketplaces like Alibaba, eBay, or specialized construction equipment suppliers. Ensure the seller offers warranties and technical support for cost-effective solutions.

Q: How does a cheap metal roofing sheet roll forming machine work?

A: These machines use a series of rollers to shape metal coils into roofing sheets. They are automated for efficiency and ideal for small-scale production, offering customizable profiles at a low cost.

Q: Are cheap standing seam metal roofing machines reliable?

A: Yes, budget-friendly standing seam machines can be reliable if they include durable components like hardened steel rollers and precise control systems. Always verify user reviews and manufacturer certifications.

Q: What features should I prioritize in a cheap metal roofing machine?

A: Focus on portability, material compatibility (e.g., steel, aluminum), and adjustable roll-forming settings. Look for energy-efficient models with easy maintenance to reduce long-term costs.

Q: Do affordable metal roofing machines come with technical support?

A: Many budget suppliers provide basic technical support and manuals. For complex operations, opt for sellers offering optional training programs or video tutorials to ensure smooth setup.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025