Affordable prices for high-quality corrugated roof sheet manufacturing machinery from leading factories

Understanding the Price of Corrugated Roof Sheet Machines from Factories

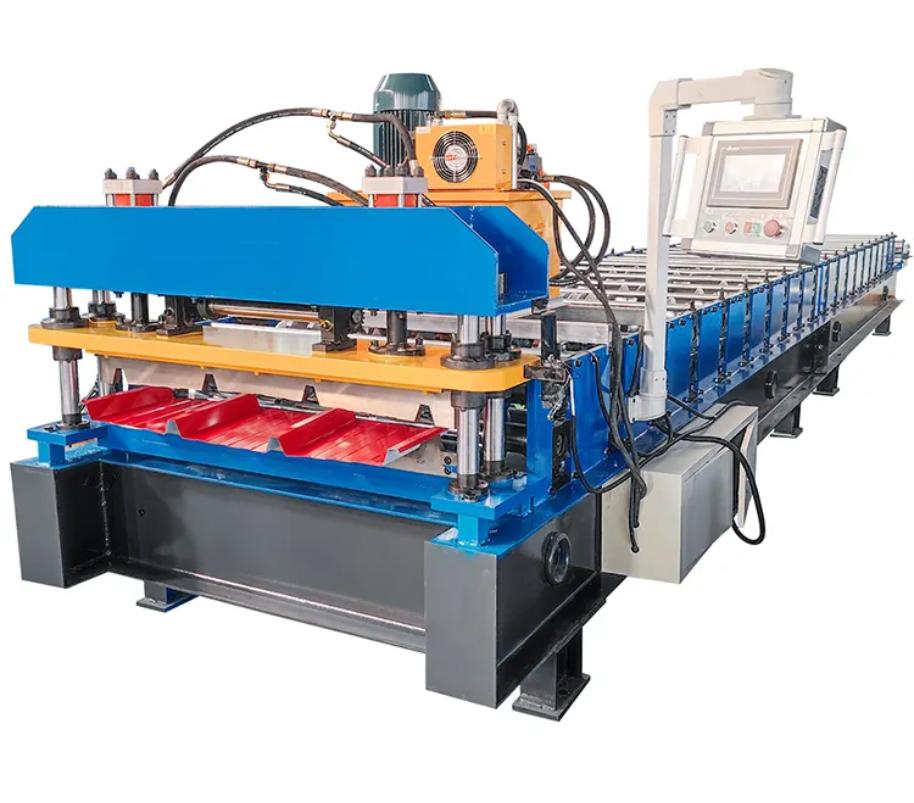

In recent years, the construction industry has seen significant growth, leading to an increased demand for efficient and cost-effective roofing solutions. One such solution is the corrugated roof sheet, known for its durability, lightweight design, and ease of installation. To meet this demand, many manufacturers have developed specialized machines that produce corrugated roof sheets. However, potential buyers often find themselves asking what is the price of a corrugated roof sheet machine from a factory, and what factors influence this cost?

Factors Influencing the Price

1. Machine Specifications The price of corrugated roof sheet machines can vary greatly depending on the machine's specifications. Machines that are capable of producing sheets with various profiles and sizes, or those that come with advanced technology for automatic cutting and stacking, often come at a premium price. Standard machines may cost less but could limit production capabilities.

2. Material Used The quality of materials used in the construction of the machine also impacts its price. High-quality components provide better durability and efficiency, thereby justifying a higher initial investment. Manufacturers that use low-grade materials may offer a cheaper option, but the long-term costs associated with repairs and maintenance can outweigh these savings.

3. Production Capacity The output capacity of a machine—measured in sheets produced per hour—also plays a significant role in determining its price. Higher-capacity machinery designed for large-scale production will typically carry a higher price tag compared to smaller, manual machines. For businesses looking to maximize output, investing in a high-capacity machine can be a smarter choice in the long run.

4. Automation Level The level of automation included in the machine can affect cost significantly. Fully automated systems, which include features such as automatic loading, feeding, and stacking, typically require a larger upfront investment but can save on labor costs and increase efficiency in the production process. Conversely, semi-automated or manual machines can be more affordable but may lead to higher labor costs and lower productivity.

corrugated roof sheet machine price factory

5. Brand Reputation and After-Sales Support The reputation of the manufacturer also influences pricing. Established brands with a track record of reliability and customer support may charge more for their machines. However, the advantages of warranty, support services, and availability of spare parts often justify the premium price for many buyers.

6. Customization Options Some factories offer tailored solutions that cater to specific production needs. Customized machines, designed according to unique specifications, can be more expensive due to the bespoke nature of their construction. Buyers should weigh the benefits of customization against the additional costs involved.

Market Price Overview

As of late 2023, the price of a basic corrugated roof sheet making machine can range from approximately $10,000 to $50,000 or more, depending on the factors mentioned above. For high-end machines with advanced features and larger production capacities, prices can soar above $100,000. It is essential for potential buyers to conduct thorough market research and compare options from various manufacturers to ensure they are making an informed decision.

Conclusion

In conclusion, the price of a corrugated roof sheet machine from a factory is influenced by multiple factors, including machine specifications, materials, production capacity, automation level, brand reputation, and customization options. While lower-priced machines may seem appealing, buyers should consider the long-term benefits of investing in a higher-quality machine that offers better durability, efficiency, and support. Understanding these dynamics will empower businesses to choose the right machine that aligns with their production goals and budget, ultimately contributing to their success in the competitive construction market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025