1월 . 22, 2025 03:17

Back to list

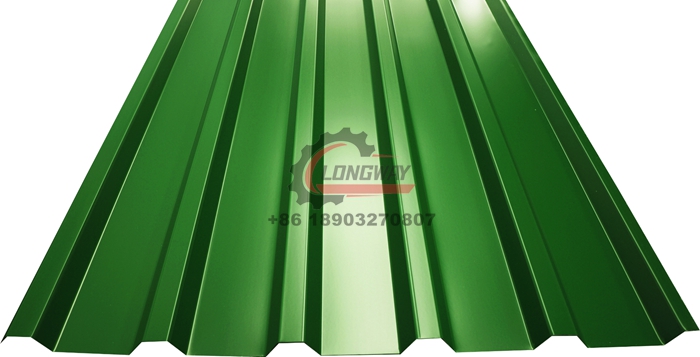

corrugated metal roofing machine

In the realm of construction and architecture, advancements in technology often lead the way toward more efficient, reliable, and sustainable practices. One such innovation is the steel roofing machine, a pivotal tool that has revolutionized the roofing industry. With an increasing focus on durability and cost-efficiency, understanding the role of these machines is crucial for professionals and homeowners alike.

Trustworthiness is an indispensable aspect that governs the purchasing decisions of customers when it comes to steel roofing machines. As with any investment in capital equipment, reliability and lifespan are critical considerations. Leading brands in the industry have built their reputations on producing robust machines that withstand high usage rates and harsh environmental conditions. Reliable customer support, comprehensive warranties, and accessible future-proof upgrades further solidify trust with users, ensuring that investments remain secure over the machinery’s operational lifetime. Moreover, sustainability is increasingly becoming a focal point within the context of steel roofing machines. The machines themselves are often crafted with recyclable materials, aligning with growing environmental consciousness. Furthermore, by optimizing material usage and reducing waste through precise cutting and forming processes, these machines contribute positively to sustainability goals. As steel remains one of the most recycled materials globally, fabricating roofing panels efficiently aligns with sustainability initiatives across various sectors. From a practical perspective, the cost-effectiveness of using steel roofing machines is a salient point for businesses and consumers. Steel, being both durable and relatively low in cost compared to other metals, provides an affordable option for high-quality roofing. When manufactured with precision and efficiency, steel roofs offer long-term resilience against weather extremities, minimal maintenance needs, and energy efficiency, providing excellent value over their lifespan. In conclusion, the integration of steel roofing machines into the construction industry marks a significant leap towards more efficient and sustainable building practices. These machines not only streamline production and installation but also enhance the quality and lifespan of roofing structures. By focusing on experience, expertise, authoritativeness, and trustworthiness, this narrative aims to provide comprehensive insights into the transformative power and enduring value of steel roofing machines in modern construction. As the industry continues to evolve, the adoption and refinement of such technologies will undoubtedly pave the way for future innovations and advancements.

Trustworthiness is an indispensable aspect that governs the purchasing decisions of customers when it comes to steel roofing machines. As with any investment in capital equipment, reliability and lifespan are critical considerations. Leading brands in the industry have built their reputations on producing robust machines that withstand high usage rates and harsh environmental conditions. Reliable customer support, comprehensive warranties, and accessible future-proof upgrades further solidify trust with users, ensuring that investments remain secure over the machinery’s operational lifetime. Moreover, sustainability is increasingly becoming a focal point within the context of steel roofing machines. The machines themselves are often crafted with recyclable materials, aligning with growing environmental consciousness. Furthermore, by optimizing material usage and reducing waste through precise cutting and forming processes, these machines contribute positively to sustainability goals. As steel remains one of the most recycled materials globally, fabricating roofing panels efficiently aligns with sustainability initiatives across various sectors. From a practical perspective, the cost-effectiveness of using steel roofing machines is a salient point for businesses and consumers. Steel, being both durable and relatively low in cost compared to other metals, provides an affordable option for high-quality roofing. When manufactured with precision and efficiency, steel roofs offer long-term resilience against weather extremities, minimal maintenance needs, and energy efficiency, providing excellent value over their lifespan. In conclusion, the integration of steel roofing machines into the construction industry marks a significant leap towards more efficient and sustainable building practices. These machines not only streamline production and installation but also enhance the quality and lifespan of roofing structures. By focusing on experience, expertise, authoritativeness, and trustworthiness, this narrative aims to provide comprehensive insights into the transformative power and enduring value of steel roofing machines in modern construction. As the industry continues to evolve, the adoption and refinement of such technologies will undoubtedly pave the way for future innovations and advancements.

Next:

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products