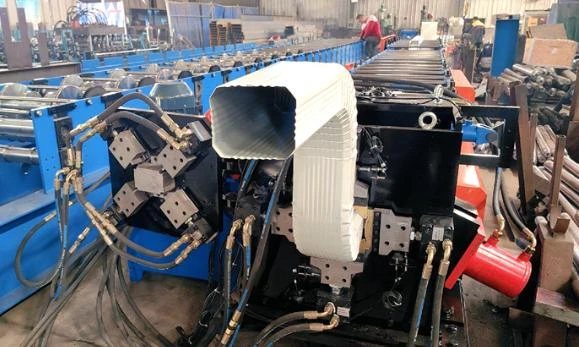

rolling shutter making machine

Understanding Rolling Shutter Making Machines A Comprehensive Overview

In the rapidly evolving world of technology and manufacturing, the need for precision and efficiency is more critical than ever. One area where this demand is particularly pronounced is in the production of rolling shutters. These devices, widely used for security, privacy, and aesthetic purposes, require a sophisticated manufacturing process to ensure quality and reliability. This is where rolling shutter making machines come into play, serving as the backbone of this industry.

What Is a Rolling Shutter?

Before delving into the machinery involved in their production, it’s essential to understand what rolling shutters are. Rolling shutters are composed of horizontal slats that can be rolled up or down, typically used in both residential and commercial settings. They provide enhanced security by creating a physical barrier against intruders while also serving to control light levels and airflow. Their versatility has made them a popular choice for storefronts, garages, and windows.

The Importance of Rolling Shutter Making Machines

The production of rolling shutters demands high levels of automation and precision. Rolling shutter making machines are essential for streamlining the manufacturing process, ensuring that each shutter meets strict quality standards. These machines are designed to perform various tasks, including cutting, slitting, and forming metal strips into slats, as well as assembling components to create the final product.

Components of a Rolling Shutter Making Machine

A typical rolling shutter making machine comprises several key components

1. Decoiler This unit feeds the raw material, usually a metal coil, into the machine. Decoilers can handle various widths and weights of coils, providing flexibility in production.

2. Roll Forming Machine Once the metal coil is fed into the machine, it passes through a series of rollers in the roll forming machine. These rollers gradually shape the material into the desired profile for the shutter slats, ensuring uniformity in design.

3. Cutting Unit After the slats are formed, they are cut to the required length. Precise cutting is essential, as uneven slats can compromise the aesthetics and functionality of the final product.

4. Assembly Line This section of the machine assembles the cut slats, as well as other components such as guides, bottom bars, and locks. Automated assembly minimizes labor costs and increases production speed.

rolling shutter making machine

5. Control System Modern rolling shutter making machines are equipped with advanced control systems that allow operators to manage the production process efficiently. These systems provide real-time data on machine performance, ensuring quick adjustments can be made to maintain quality.

Advantages of Using Rolling Shutter Making Machines

The integration of rolling shutter making machines into manufacturing processes offers several advantages

- Increased Production Speed Automation significantly enhances the speed of production. Machines can operate continuously and with minimal downtime, resulting in higher output.

- Consistency in Quality With machines handling the intricate tasks of cutting and forming, manufacturers can ensure a consistent quality across every product. This is particularly important for businesses that require uniformity in their offerings.

- Cost-Efficiency While the initial investment in machinery may be substantial, the long-term savings in labor and reduced material waste can significantly improve a company’s bottom line.

- Customization Options Many modern machines come with programmable features that allow manufacturers to produce custom designs and sizes according to client specifications, thus expanding their market reach.

The Future of Rolling Shutter Manufacturing

As technology continues to advance, the rolling shutter manufacturing sector is poised for further innovations. Developments in smart manufacturing and Industry 4.0 principles are likely to influence the design and functionality of rolling shutter making machines. Future machines may incorporate IoT capabilities, allowing for better monitoring and control over production processes. Additionally, advancements in materials science may lead to the availability of lighter yet stronger materials, further enhancing the performance of rolling shutters.

Conclusion

Rolling shutter making machines play a vital role in the efficiency and quality of rolling shutter production. As the industry continues to evolve, the machines will likewise adapt, incorporating new technologies that enhance their functionality and ease of use. For manufacturers in this sector, investing in advanced rolling shutter making machines not only improves productivity but also positions them to meet the demands of an ever-changing marketplace. Whether for security, aesthetics, or energy efficiency, the role of these machines is indispensable in today’s manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025