Exploring the Latest Innovations in Transformer Architectures for Natural Language Processing

The Evolution and Applications of Rollformers in Modern Manufacturing

Rollformers have revolutionized the manufacturing landscape by providing efficient solutions for creating metal products with precision and speed. This innovative technology has evolved over the years, offering a range of advantages that cater to various industries including construction, automotive, and appliance manufacturing. Understanding the role of rollformers in modern production processes is crucial for companies aiming to enhance their efficiency and product quality.

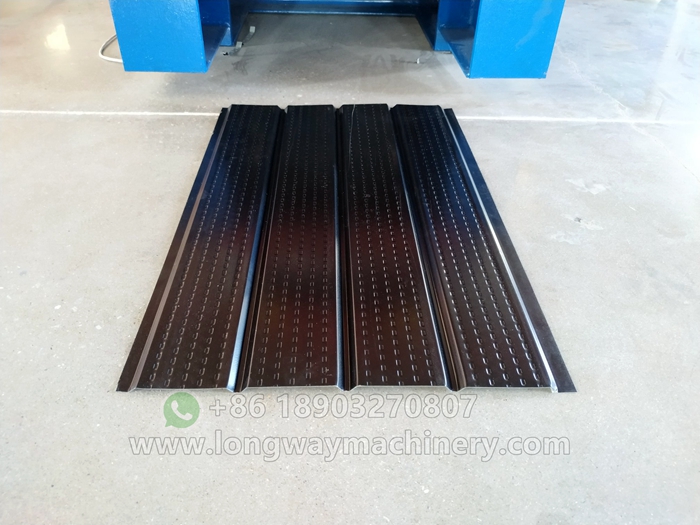

At its core, a rollformer is a machine that shapes metal sheets into desired profiles through a series of contoured rollers. The process begins with a flat sheet of metal, which is fed through the collection of rollers, each designed to progressively shape the material. This continuous process allows for the production of long lengths of metal profiles without any seams, which is ideal for structural applications. The flexibility of rollformers makes them suitable for a wide array of product designs, from simple brackets to complex roofing panels.

One of the most significant advantages of using rollformers is their efficiency. Traditional metal forming methods often involve secondary processes such as cutting and assembling components, which can be time-consuming and labor-intensive. In contrast, rollforming is a continuous operation that minimizes waste and reduces the need for additional processing. This efficiency not only lowers production costs but also shortens lead times, giving companies a competitive edge in fast-paced markets.

Another notable feature of rollformers is their ability to produce high volumes of products with consistent quality. The automation of the rollforming process ensures that each piece meets strict tolerances, reducing the risk of defects. Many rollformers are equipped with advanced technology such as computer numerical control (CNC) systems that allow for precise adjustments and monitoring throughout the manufacturing process. This level of control is particularly beneficial in industries where quality standards are paramount.

rollformers

Applications of rollformers are vast and varied. In the construction industry, rollformed products are used for roofing, framing, and structural support systems. They provide lightweight yet durable solutions that can withstand challenging environmental conditions. The automotive industry also benefits significantly from rollforming, utilizing it to create components such as chassis and structural beams that enhance vehicle safety and performance.

Moreover, the appliance manufacturing industry employs rollforged parts in products ranging from refrigerators to washing machines. These components, often requiring intricate shapes and designs, highlight the versatility of rollforming technology. As consumer demands for higher quality and customized products increase, rollformers continue to adapt, offering customized solutions tailored to specific needs.

The evolution of technology has also influenced the rollforming process. Innovations such as integrated automation, real-time monitoring, and advanced software have enhanced the capabilities of modern rollformers. With the rise of Industry 4.0, manufacturers are increasingly leveraging data analytics to optimize production lines, predict maintenance needs, and improve overall efficiency. As such, rollformers are becoming not just machines but integral components of smart manufacturing systems.

In conclusion, rollformers have become an essential tool in modern manufacturing, offering efficient, high-quality, and versatile solutions for various industries. Their ability to streamline production processes while maintaining product integrity makes them invaluable to manufacturers aiming to meet the fast-evolving demands of the market. As technology continues to advance, the future of rollforming looks promising, paving the way for even more innovative applications and improved manufacturing practices. By embracing these developments, industries can ensure they remain competitive in an ever-changing global landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025