purlin roll forming machine companies

An Overview of Purlin Roll Forming Machine Companies

In the modern construction industry, the demand for high-quality steel components has surged, leading to the emergence of specialized machinery catering to this need. Among these, purlin roll forming machines have gained significant attention for their ability to produce purlins – essential structural components used in the framing of buildings. This article delves into the world of purlin roll forming machine companies, exploring their significance, the technology involved, and the factors to consider when choosing a provider.

Understanding Purlin Roll Forming Machines

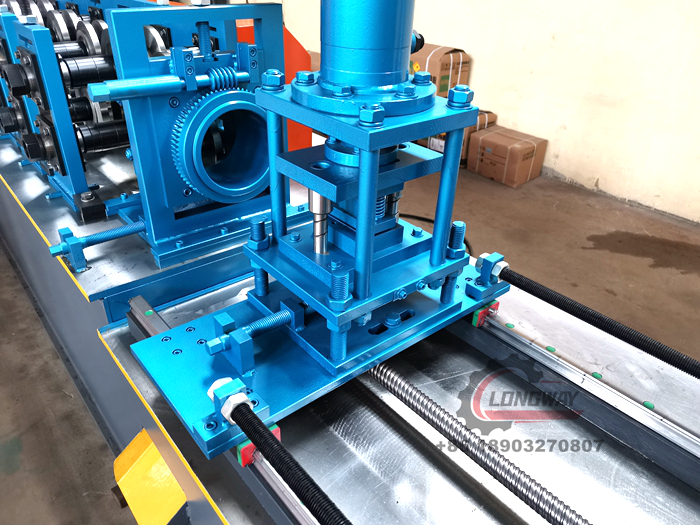

Purlin roll forming machines are designed to produce purlins from steel sheets by continuously bending and shaping them into desired profiles. These machines utilize advanced technology to ensure precision and efficiency in production, allowing for the manufacturing of C and Z-shaped purlins that serve various construction purposes, such as roof support and wall bracing. The process typically involves feeding raw steel sheets into the machine, which then rolls and forms the sheets into the desired shapes with specified dimensions.

The Role of Purlin Roll Forming Machine Companies

Several companies specialize in the production and sale of purlin roll forming machines. These firms are crucial in providing the construction industry with the tools needed to build robust and durable structures. Leading manufacturers invest in research and development to enhance machine performance, efficiency, and versatility. They offer a range of products that cater to different market needs, including customized machines that can handle various materials and specifications.

Key Features to Consider

When selecting a purlin roll forming machine company, several factors should be considered to ensure you make the right choice

purlin roll forming machine companies

1. Quality and Reliability Look for companies known for their high-quality machinery. Reliable machines are essential for minimizing downtime and maximizing production efficiency.

2. Technology and Innovation Leading companies often leverage advanced technology, such as automation and computer numerical control (CNC), in their machines. These innovations enhance precision and ease of operation.

3. Customization Options A good manufacturer should be able to offer customized solutions tailored to specific production needs. This flexibility is vital for businesses with unique requirements.

4. After-Sales Support Consider the level of after-sales service provided by the manufacturer. Support in terms of maintenance, repairs, and parts availability can significantly impact operational efficiency.

5. Reputation and Reviews Research the company's reputation in the industry by reading customer reviews and testimonials. A solid track record is often indicative of a reliable partner.

Conclusion

As the construction landscape evolves, the importance of efficient and precise manufacturing processes becomes paramount. Purlin roll forming machine companies stand at the forefront of this evolution, providing essential tools that enhance productivity and quality in construction projects. By considering factors such as quality, technology, customization, support, and reputation, businesses can make informed decisions when selecting a purlin roll forming machine provider. Ultimately, the right choice leads to improved operational efficiency, timing, and cost-effectiveness in building projects, contributing to the overall success of the construction industry.

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025

-

Revolutionizing Door Frame Production: The Power of Modern MachinesNewsMay.09, 2025

-

Revolutionary Machines for Roller Shutter and Garage DoorsNewsMay.09, 2025

-

Everything You Need to Know About Gutter Roll Forming MachinesNewsMay.09, 2025

-

Efficiency in Coil Handling with Hydraulic Decoiler MachinesNewsMay.09, 2025

-

Downspout Roll Forming Machines and Their ValueNewsMay.09, 2025

-

Revolutionizing the Door Frame Industry: Key Insights on Roll Forming MachinesNewsApr.18, 2025