3월 . 04, 2025 00:59

Back to list

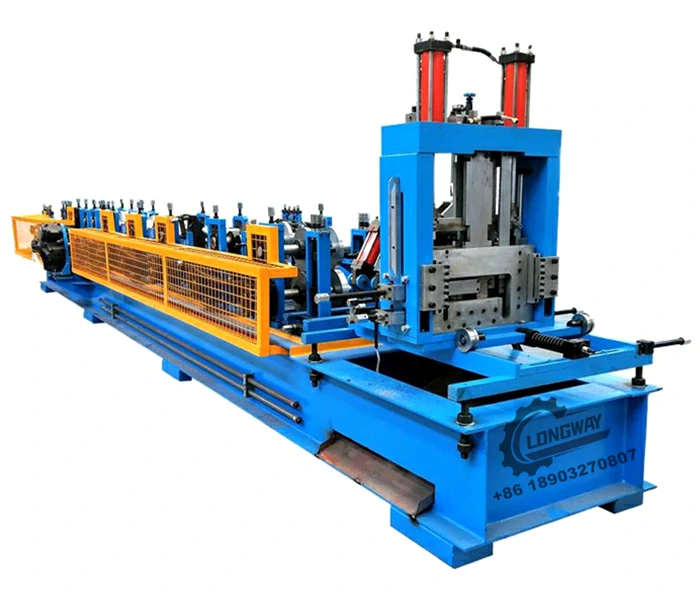

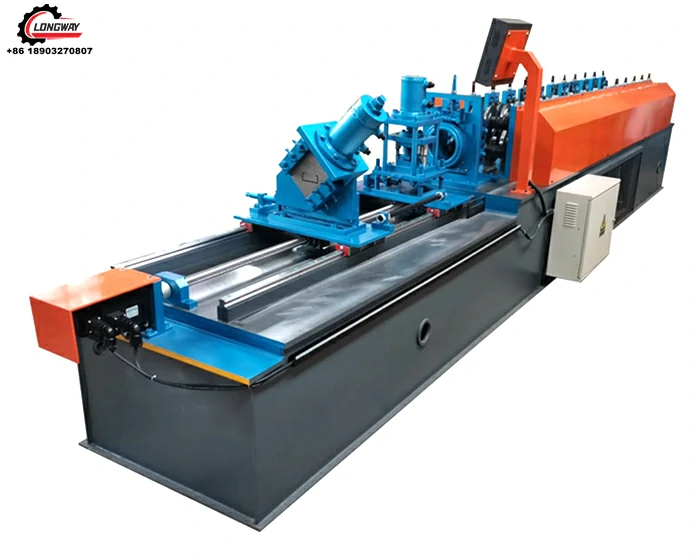

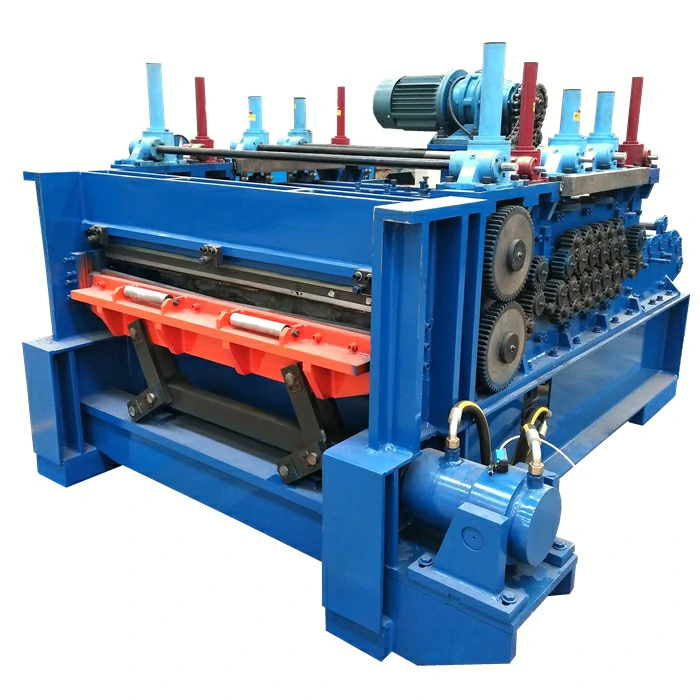

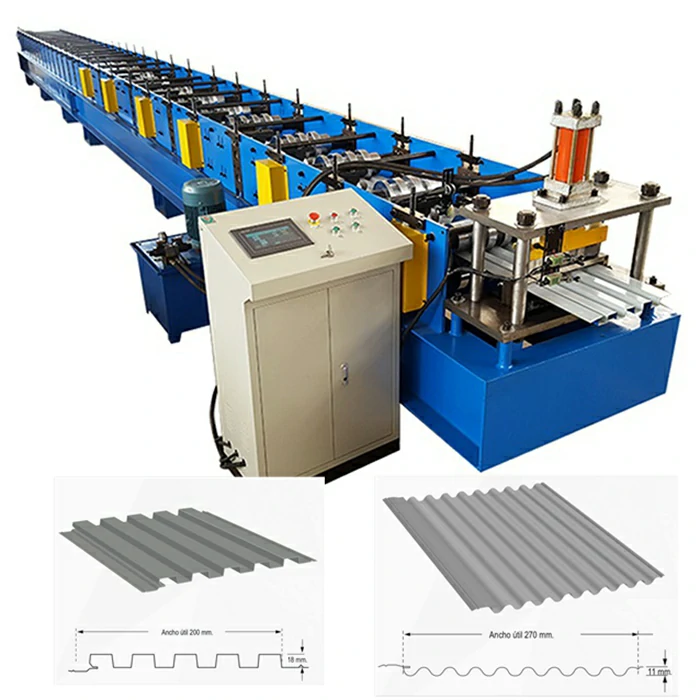

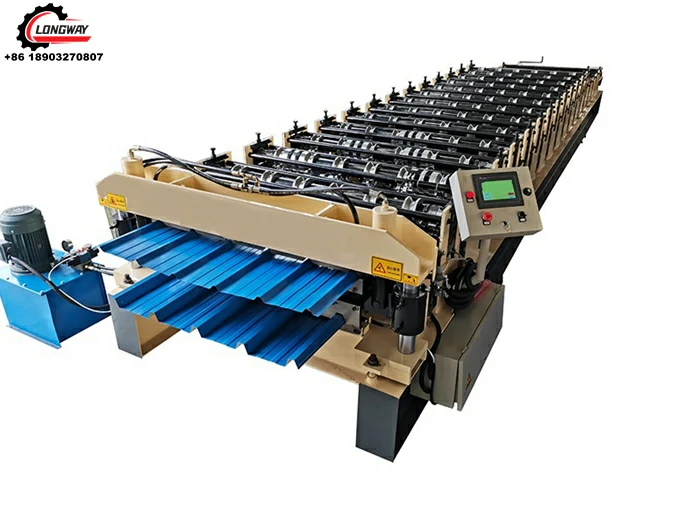

profile roll forming machine supplier

Choosing the right profile roll forming machine supplier can significantly impact your manufacturing capabilities and operational efficiency. This is a decision that involves a deep understanding of roll forming technology as well as the industry-specific requirements for precision and reliability.

Authoritativeness in the field of roll forming machine suppliers can be gauged through industry recognition, certifications, and partnerships. Suppliers who engage with recognized standardizing bodies and maintain industry certifications demonstrate a level of compliance and quality assurance that reassures customers of their reliability. Moreover, partnerships with leading manufacturers and industry associations further cement their authoritative position. An authoritative supplier is one whose machines become benchmarks in the industry, lauded for their robustness and technological prowess. Trustworthiness is the final pillar and arguably the most crucial aspect. A trustworthy supplier provides transparency in their operations, from pricing to post-purchase support. When purchasing such sophisticated machinery, clear and open communication is key to forming a partnership rather than a mere transactional relationship. Look for suppliers who offer comprehensive after-sales support, warranties, and a transparent service structure. This confidence can often be evidenced through client testimonials and case studies. A supplier committed to maintaining long-term relationships will prioritize the success and satisfaction of their clients, ensuring that their machines deliver as promised. A holistic approach is necessary when evaluating profile roll forming machine suppliers, considering not only the machinery's specifications but also the supplier's overall credibility and capability. It is critical to invest in a supplier that embodies experience, expertise, authoritativeness, and trustworthiness, ensuring that the machinery contributes positively to production efficiencies and quality outcomes. These four pillars not only safeguard your investment but also advance your competitive edge in the market through enhanced manufacturing capabilities.

Authoritativeness in the field of roll forming machine suppliers can be gauged through industry recognition, certifications, and partnerships. Suppliers who engage with recognized standardizing bodies and maintain industry certifications demonstrate a level of compliance and quality assurance that reassures customers of their reliability. Moreover, partnerships with leading manufacturers and industry associations further cement their authoritative position. An authoritative supplier is one whose machines become benchmarks in the industry, lauded for their robustness and technological prowess. Trustworthiness is the final pillar and arguably the most crucial aspect. A trustworthy supplier provides transparency in their operations, from pricing to post-purchase support. When purchasing such sophisticated machinery, clear and open communication is key to forming a partnership rather than a mere transactional relationship. Look for suppliers who offer comprehensive after-sales support, warranties, and a transparent service structure. This confidence can often be evidenced through client testimonials and case studies. A supplier committed to maintaining long-term relationships will prioritize the success and satisfaction of their clients, ensuring that their machines deliver as promised. A holistic approach is necessary when evaluating profile roll forming machine suppliers, considering not only the machinery's specifications but also the supplier's overall credibility and capability. It is critical to invest in a supplier that embodies experience, expertise, authoritativeness, and trustworthiness, ensuring that the machinery contributes positively to production efficiencies and quality outcomes. These four pillars not only safeguard your investment but also advance your competitive edge in the market through enhanced manufacturing capabilities.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products