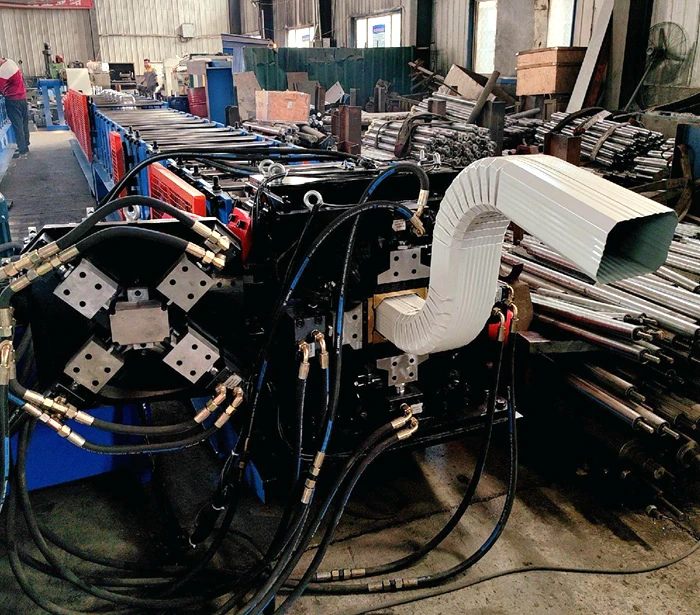

gutter forming machine

The Gutter Forming Machine Revolutionizing Construction and Home Improvement

In the realm of modern construction and home improvement, efficiency and precision are paramount. Among the plethora of machinery designed to streamline these processes, the gutter forming machine stands out as a revolutionary tool that significantly enhances the quality and efficiency of gutter installation. This article explores the workings of the gutter forming machine, its benefits, and its impact on the construction industry.

What is a Gutter Forming Machine?

A gutter forming machine is specialized equipment used to manufacture seamless gutters from metal sheets, typically aluminum, steel, or copper. This machine automates the process of cutting, bending, and shaping the metal into the desired gutter profile, enabling seamless installation that minimizes leaks and reduces maintenance in the long run.

How Does It Work?

The operation of a typical gutter forming machine is remarkably straightforward yet highly efficient

1. Material Feeding Metal coils are loaded onto the machine. These coils are the raw material from which gutters are formed.

2. Roll Forming The machine uses a series of rollers to shape the metal into a predefined profile. As the metal is fed through, it passes through different stations where rollers gradually bend it into the desired shape of a gutter.

3. Cutting Once the gutter is shaped, it is cut to the specified lengths. Some advanced machines even allow for customized lengths on demand, eliminating waste and improving efficiency.

4. Seaming In some cases, the machine can also create seams that enhance the strength of the gutter system.

5. Finish and Quality Control The finished gutters are typically inspected for quality and precision before being sent out for installation.

Benefits of Using a Gutter Forming Machine

gutter forming machine

The adoption of a gutter forming machine offers numerous advantages

1. Efficiency The automation of gutter production significantly reduces the time required for installation compared to traditional methods. What used to take hours can now be completed in minutes, allowing contractors to take on more projects in less time.

2. Precision Gutter forming machines are engineered to deliver consistent, high-quality results. The precision with which they operate ensures that each gutter fits perfectly, reducing the potential for leaks and other issues associated with poorly aligned gutters.

3. Cost-Effectiveness While the initial investment in a gutter forming machine may be substantial, the savings generated over time are considerable. Reduced labor costs, minimized material waste, and fewer callbacks due to installation errors contribute to overall cost efficiency.

4. Customization These machines can be adjusted to create various styles and sizes of gutters, allowing contractors to meet the specific needs of their clients without ordering pre-made products. This customization capability is a significant advantage in a market where client preferences can vary widely.

5. Durability and Quality Seamless gutters produced by forming machines are typically stronger and more durable than traditional sections of gutters that are joined together. This minimizes the risk of leaks and prolongs the life of the gutter system, providing great value to homeowners.

Impact on the Construction Industry

The introduction and widespread use of gutter forming machines have had a transformative effect on the construction industry. By improving the efficiency and accuracy of gutter installations, contractors can deliver higher-quality work in less time, thus enhancing customer satisfaction. The ability to customize gutter installations also enables contractors to differentiate their services in a competitive market.

Moreover, as awareness grows regarding the environmental impact of construction practices, the reduced material waste that comes with precision manufacturing becomes increasingly appealing. Gutter forming machines contribute to sustainable building practices by minimizing off-cuts and excess materials.

Conclusion

In summary, the gutter forming machine represents a significant advancement in construction technology, offering a multitude of benefits that enhance efficiency, precision, and cost-effectiveness. As the industry continues to evolve, tools like the gutter forming machine will play a crucial role in shaping the future of construction and home improvement, delivering high-quality results that meet the demands of modern consumers. With the ability to produce customized and seamless gutters quickly and accurately, these machines not only make life easier for contractors but also provide homeowners with durable and reliable solutions for their guttering needs.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025