2월 . 17, 2025 12:13

Back to list

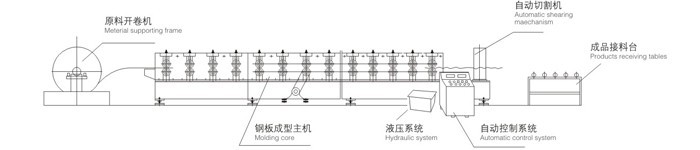

double deck roofing sheet roll forming machine

The world of construction and manufacturing has witnessed a significant evolution with the development of advanced machinery such as the double deck roofing sheet roll forming machine. This revolutionary equipment is a testament to the continuous technological advancement in the roll forming industry, providing efficient solutions for producing high-quality roofing materials.

The quality and durability of roofing materials produced by double deck roll forming machines are unparalleled. Using high-tensile steel, these machines produce sheets that withstand severe weather conditions and maintain structural integrity over long periods. This guarantees that end consumers receive only the most reliable products, fostering brand loyalty and repeat business for manufacturers. In terms of sustainability, double deck roll forming machines are a green innovation in the sector. They minimize noise pollution, consume less power compared to traditional machinery, and produce less scrap. This translates to a smaller carbon footprint, which is essential at a time when industries are being encouraged to adopt greener manufacturing practices. Experts in the roll forming industry understand the importance of investing in machinery that offers flexibility, efficiency, and reliability. The double deck roofing sheet roll forming machine is a wise investment for any manufacturer wanting to stay competitive in an increasingly demanding marketplace. As the machine supports a variety of metal thicknesses and coatings, businesses can expand their product offerings without needing additional machines, thereby maximizing their investment. As for trustworthiness, manufacturers of these machines focus on providing premium customer service, which includes thorough training, regular maintenance schedules, and robust after-sales support. This ensures that any technical issues are swiftly addressed, minimizing disruption to production lines, and further securing the reliability of using double deck roll forming machines. In conclusion, double deck roofing sheet roll forming machines are not just a technical marvel; they represent a strategic investment for manufacturers dedicated to excellence in quality and efficiency. With their ability to produce diverse profiles quickly and cost-effectively, they empower companies to meet customer needs while staying ahead of industry trends. Those adopting these machines are not only enhancing their operational capabilities but are also reinforcing their commitment to innovation and environmental responsibility.

The quality and durability of roofing materials produced by double deck roll forming machines are unparalleled. Using high-tensile steel, these machines produce sheets that withstand severe weather conditions and maintain structural integrity over long periods. This guarantees that end consumers receive only the most reliable products, fostering brand loyalty and repeat business for manufacturers. In terms of sustainability, double deck roll forming machines are a green innovation in the sector. They minimize noise pollution, consume less power compared to traditional machinery, and produce less scrap. This translates to a smaller carbon footprint, which is essential at a time when industries are being encouraged to adopt greener manufacturing practices. Experts in the roll forming industry understand the importance of investing in machinery that offers flexibility, efficiency, and reliability. The double deck roofing sheet roll forming machine is a wise investment for any manufacturer wanting to stay competitive in an increasingly demanding marketplace. As the machine supports a variety of metal thicknesses and coatings, businesses can expand their product offerings without needing additional machines, thereby maximizing their investment. As for trustworthiness, manufacturers of these machines focus on providing premium customer service, which includes thorough training, regular maintenance schedules, and robust after-sales support. This ensures that any technical issues are swiftly addressed, minimizing disruption to production lines, and further securing the reliability of using double deck roll forming machines. In conclusion, double deck roofing sheet roll forming machines are not just a technical marvel; they represent a strategic investment for manufacturers dedicated to excellence in quality and efficiency. With their ability to produce diverse profiles quickly and cost-effectively, they empower companies to meet customer needs while staying ahead of industry trends. Those adopting these machines are not only enhancing their operational capabilities but are also reinforcing their commitment to innovation and environmental responsibility.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products