High-Quality Corrugated Roof Sheet Roll Forming Machine Manufacturers

Corrugated Roof Sheet Roll Forming Machine Manufacturers An Overview

In recent years, the demand for durable and efficient roofing solutions has significantly increased across various sectors, prompting a surge in the manufacturing of corrugated roof sheet roll forming machines. These machines are essential in producing high-quality corrugated sheets, which are widely employed in residential, commercial, and industrial construction projects due to their robustness and versatility.

What are Corrugated Roof Sheet Roll Forming Machines?

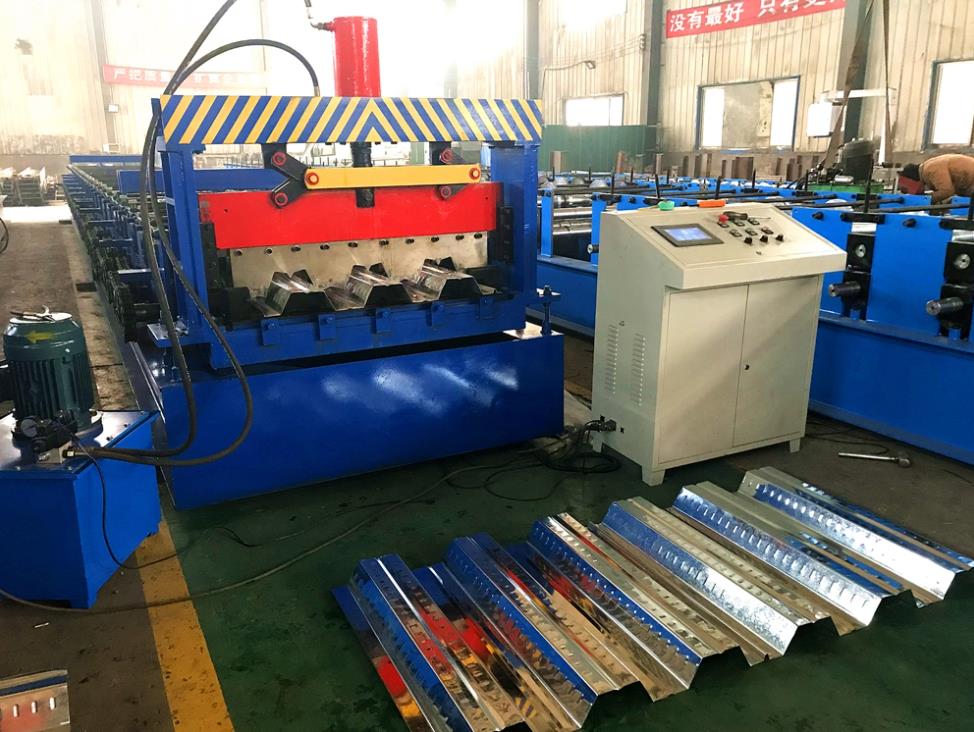

Corrugated roof sheet roll forming machines are specialized equipment designed to fabricate corrugated sheets from metal, such as galvanized steel or aluminum. The roll forming process involves feeding a flat metal coil through a series of rollers that gradually shape it into the desired corrugated profile. This not only enhances the aesthetic appeal of roofs but also adds strength and durability, making them ideal for various weather conditions.

Key Features and Benefits

Manufacturers of these machines are consistently innovating to offer features that enhance productivity and efficiency. Some key attributes of modern corrugated roof sheet roll forming machines include

1. High Production Speed Advanced machinery can produce large quantities of corrugated sheets in a short time frame, catering to high-demand construction projects.

2. Customizable Designs Many manufacturers provide customizable options, allowing clients to choose specific designs, thicknesses, and materials for their corrugated sheets.

3. Energy Efficiency Modern machines are designed to reduce energy consumption while maximizing output, making them eco-friendly choices for manufacturers.

corrugated roof sheet roll forming machine manufacturers

Choosing a Manufacturer

When selecting a corrugated roof sheet roll forming machine manufacturer, several factors should be considered

- Experience and Expertise Look for manufacturers with a solid history in the industry. Experience often translates to better design and engineering capabilities.

- Quality Assurance Ensure that the manufacturer adheres to international quality standards, utilizing reliable materials and processes.

- Customer Support and Service A reputable manufacturer will offer comprehensive after-sales support, including maintenance services, spare parts availability, and technical assistance.

- Client Testimonials Research feedback from previous clients to gauge the manufacturer's reliability and the performance of their machinery.

Future Trends

As the construction industry continues to evolve, the demand for innovative and efficient roofing solutions will rise. Manufacturers are increasingly integrating technology into their machinery, such as automation and IoT capabilities, to enhance operational efficiency and data monitoring.

In conclusion, corrugated roof sheet roll forming machines play a crucial role in modern construction. With various manufacturers stepping up to meet the growing demand, it is essential for buyers to conduct thorough research and choose a manufacturer that aligns with their quality and operational requirements. By investing in high-quality roll forming machines, construction businesses can ensure they produce durable and reliable roofing solutions to meet the needs of a dynamic market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025