china cold roll forming machine

The Importance of Cold Roll Forming Machines in China’s Manufacturing Industry

In recent years, China has solidified its position as a global manufacturing powerhouse, and at the heart of this industrial growth are advanced technologies such as cold roll forming machines. These machines play a crucial role in the fabrication of high-quality metal products used in various industries, including construction, automotive, and appliance manufacturing. As the demand for precision-engineered components continues to rise, understanding the significance of cold roll forming machines is essential for anyone involved in manufacturing or looking to invest in this sector.

Understanding Cold Roll Forming

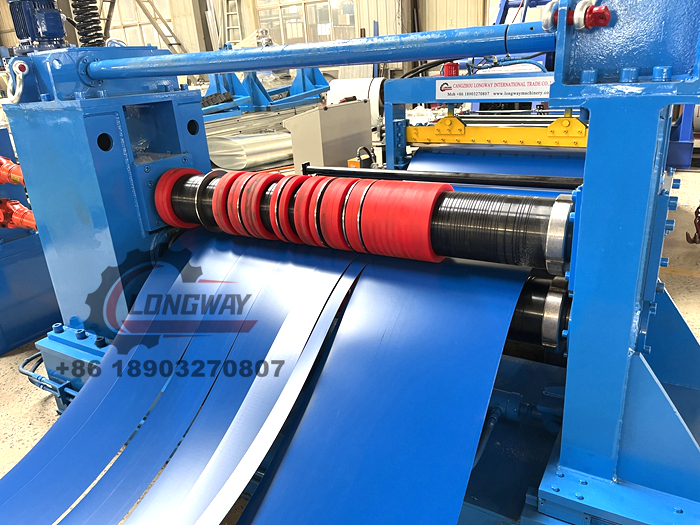

Cold roll forming is a process that involves the continuous bending of metal sheets or strips into desired shapes at room temperature. This method utilizes multiple rollers to gradually shape the metal into the final product without requiring additional heating. The primary advantage of cold roll forming is its ability to produce complex profiles with tight tolerances, which ensures that the finished products meet strict quality requirements.

Cold roll forming machines are capable of processing a variety of materials, including steel, aluminum, and other alloys. They can produce a wide range of products, from simple components such as brackets and channels to customized profiles for specific applications. Additionally, cold roll forming is known for its efficiency, as it minimizes waste and reduces production time compared to traditional manufacturing methods.

The Role of Cold Roll Forming Machines in China

As one of the largest producers of metalworking machinery, China has seen a substantial increase in the adoption of cold roll forming technology. The country's extensive industrial base has led to a higher demand for machine tools that can produce high-quality metal components at competitive prices. Cold roll forming machines have become essential to this ecosystem, enabling manufacturers to create a vast array of products cost-effectively.

1. Efficiency and Cost-Effectiveness Cold roll forming machines are designed for high throughput, allowing manufacturers to produce large volumes of products quickly. The process is energy-efficient and typically results in lower operational costs due to less material waste and fewer production steps required compared to other metal forming techniques.

china cold roll forming machine

2. Customization and Versatility The ability to easily customize the design of the tooling makes cold roll forming an attractive option for manufacturers that require specific shapes and sizes. This flexibility is particularly beneficial in sectors where unique components are necessary, such as in the construction of buildings and infrastructure.

3. Quality and Precision Cold roll forming machines produce components with excellent dimensional accuracy and surface finishes. This high level of precision is crucial in industries such as automotive manufacturing, where even minor discrepancies can lead to significant issues in assembly and operation.

4. Sustainability As the world increasingly focuses on sustainable manufacturing practices, cold roll forming machines offer an environmentally friendly alternative due to their minimal waste generation and energy-efficient operations. This aligns with global trends toward sustainable urban development and the reduction of carbon footprints.

Future Prospects

Looking ahead, the market for cold roll forming machines in China is expected to grow significantly as manufacturers seek to enhance production capabilities and meet the ever-increasing demand for high-quality metal products. Emerging technologies, such as automation and Industry 4.0, will further transform the cold roll forming process, making it more efficient and integrated into smart manufacturing systems.

Moreover, as China continues to expand its export capabilities, the global market for cold roll forming machines will likely witness stronger competition and innovation. Manufacturers that leverage these advances will be well-positioned to capitalize on the opportunities presented by both domestic and international markets.

Conclusion

Cold roll forming machines are a vital component of China’s manufacturing landscape. Their efficiency, precision, and adaptability not only drive productivity but also ensure that manufacturers can meet the growing demands of various sectors. As the industry evolves, investing in advanced cold roll forming technology will be key for companies aiming to stay competitive in an increasingly complex global supply chain.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025