Affordable Standing Seam Roof Panel Production Equipment Solutions for Your Needs

Affordable Standing Seam Forming Machines Revolutionizing the Roofing Industry

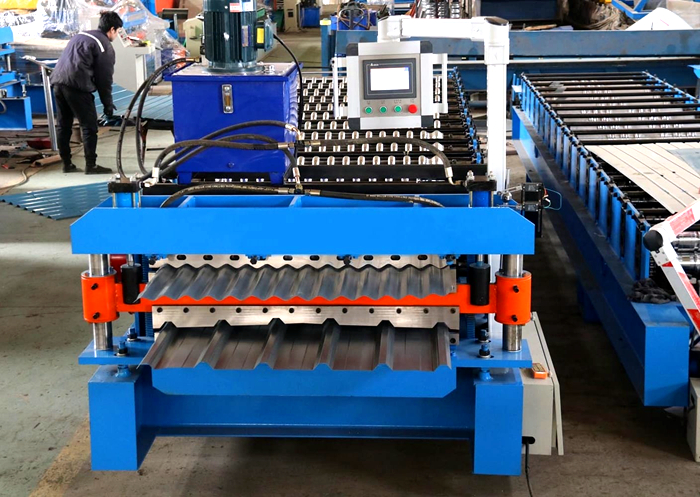

In the competitive landscape of modern construction, efficiency and cost-effectiveness are paramount. One of the critical components in roofing solutions is the standing seam metal roof, known for its durability, weather resistance, and aesthetics. However, to meet the growing demand for such roofs, manufacturers require advanced machinery. Enter the cheap standing seam forming machine, an innovation that promises to optimize production without sacrificing quality.

A standing seam roof is recognized for its raised seams, which are vertically oriented and interlock, making it less susceptible to water infiltration. This style has gained popularity in both residential and commercial buildings, primarily due to its longevity and minimal maintenance requirements. As the market for standing seam roofs expands, the need for efficient manufacturing processes becomes increasingly critical. This is where the standing seam forming machine comes into play.

Traditionally, investing in state-of-the-art metal forming machinery could strain budgets, particularly for smaller businesses. However, the introduction of affordable standing seam forming machines has democratized access to this technology. Manufacturers can now produce high-quality metal roofing panels at a fraction of the initial investment previously required. These machines combine advanced forming technology with cost-effective solutions, allowing businesses of varied sizes to enter or expand in the roofing market.

The technology behind these machines is both innovative and user-friendly. Most cheap standing seam forming machines are designed with simplicity in mind, enabling operators to easily set up and switch between different panel profiles. This flexibility is crucial for manufacturers catering to diverse client needs. Moreover, advancements in automation have made it possible to reduce manual labor significantly, thus enhancing productivity and minimizing human error.

cheap standing seam forming machine

One of the standout features of these machines is their production speed. A modern standing seam forming machine can produce panels rapidly, allowing for high-volume production without compromising on quality. Manufacturers can respond to market demands more quickly, reducing lead times and increasing customer satisfaction. Furthermore, these machines are designed for easy transport and setup, making them ideal for on-site production, which can simplify logistics and reduce costs.

Cost savings extend beyond the initial investment in the machinery itself. With the capability to produce standing seam panels in-house, businesses can drastically cut down on material costs and transportation expenses. This vertical integration allows manufacturers to offer competitive pricing to their clients, thereby increasing their market share.

Moreover, the reliability and longevity of standing seam roofs contribute to their growing popularity among consumers. As these roofing solutions become more prevalent, the demand for affordable and efficient manufacturing options will continue to rise. The development of cost-effective standing seam forming machines is a crucial step in meeting this demand, paving the way for sustainable growth within the industry.

In conclusion, cheap standing seam forming machines are set to transform the roofing manufacturing landscape. By offering advanced technology at a lower price point, these machines empower businesses to operate more efficiently and competitively. As the world moves towards innovative building solutions, the adoption of affordable standing seam forming machines will play a pivotal role in shaping the future of roofing production. Companies can look forward to greater productivity, reduced costs, and the ability to meet the rising demand for quality metal roofing solutions. Embracing this technology is not just an investment in machinery; it's an investment in the future of construction.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025