auto c purlin forming machine factory

The Importance of Automatic C Purlin Forming Machines in Modern Construction

In recent years, the construction industry has witnessed a significant transformation with the advent of advanced machinery designed to streamline operations and enhance efficiency. One such crucial innovation is the automatic C purlin forming machine. This equipment plays a vital role in the formation of C-shaped purlins, which are essential components in various structural applications, especially in the erection of steel buildings, warehouses, and industrial facilities.

Understanding C Purlins

C purlins are structural members used to support roof and wall panels in construction. Their shape provides excellent stability and strength, making them ideal for load-bearing applications. These purlins are essential in the construction of frameworks for commercial buildings, agricultural structures, and even residential projects. Traditional methods of manufacturing C purlins often involve labor-intensive techniques, which can lead to inconsistencies in quality and dimensions. This is where automated machinery comes into play.

The Role of Automatic C Purlin Forming Machines

Automatic C purlin forming machines revolutionize the process of producing these vital structural components by integrating advanced technology and automation. These machines are designed to efficiently process metal sheets, transforming them into precision-engineered C purlins with minimal human intervention. The benefits of using such machines are manifold

1. Efficiency and Speed Automatic C purlin forming machines operate at high speeds, dramatically reducing the time required for production. This efficiency allows manufacturers to meet tight project deadlines and increase overall output.

2. Precision Engineering With computer-controlled systems, these machines ensure high levels of accuracy in the dimensions and shapes of the purlins produced. This precise engineering minimizes waste and reduces the need for extensive on-site adjustments.

3. Cost-Effectiveness Although the initial investment in an automatic C purlin forming machine may be significant, the long-term savings are substantial. Reduced labor costs, minimized material waste, and increased production capabilities lead to lower overall operational costs.

4. Versatility Modern machines come equipped with customizable features that allow manufacturers to produce various profiles and sizes of C purlins. This versatility caters to different project requirements and client preferences, enhancing market competitiveness.

auto c purlin forming machine factory

5. Improved Safety Automation reduces the extent of manual labor required in the production process. As a result, there is a lower risk of workplace accidents, contributing to a safer working environment.

The Manufacturing Process

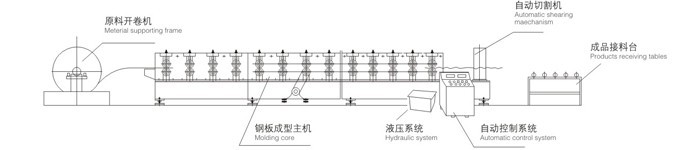

The operation of an automatic C purlin forming machine generally involves several key stages

1. Material Feeding Steel coils are fed into the machine, where they are unwound and straightened.

2. Roll Forming The straightened metal sheets pass through a series of rollers that shape them into a C profile as they move through the machine.

3. Cutting Once the desired length is achieved, an integrated cutting system precisely trims the purlins to specified lengths.

4. Punching and Notching Additional features such as holes for fastening and notches for connections can be incorporated during the forming process, enhancing the functionality of the purlins.

5. Finished Product The completed C purlins are then stacked for easy handling and transport to the construction site.

Conclusion

In an era where efficiency, precision, and sustainability are paramount in the construction industry, the automatic C purlin forming machine represents a significant advancement. By automating the production of C purlins, manufacturers not only enhance their operational capabilities but also contribute to the overall quality and reliability of construction projects. As the demand for robust and cost-effective building solutions continues to grow, investing in automatic C purlin forming machinery is becoming increasingly essential for forward-thinking construction businesses.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025