Aluminum Sheet Embossing Equipment for Precision Design and Custom Finishing Solutions

The Benefits and Applications of Aluminium Embossing Machines

Aluminium embossing machines play a crucial role in the manufacturing and design industries, enabling the creation of intricate patterns and textures on aluminium sheets. These machines utilize advanced technology to apply decorative and functional designs, making aluminium products not only more aesthetically appealing but also enhancing their physical properties.

One of the primary benefits of using aluminium embossing machines is precision. Modern machines are equipped with computer-controlled systems that allow for high levels of accuracy in the embossing process. This precision ensures that the final product meets the exact specifications required by various industries, including automotive, packaging, and construction. With the ability to produce detailed patterns, manufacturers can create custom designs that cater to specific market needs, giving them a competitive edge.

Another significant advantage of aluminium embossing is its ability to improve the surface properties of aluminium sheets. The embossing process increases the surface area, which can enhance adhesion for paints and coatings, thereby extending the life of the product. Additionally, embossed aluminium surfaces can provide better slip resistance, making them ideal for use in flooring and other applications where safety is paramount.

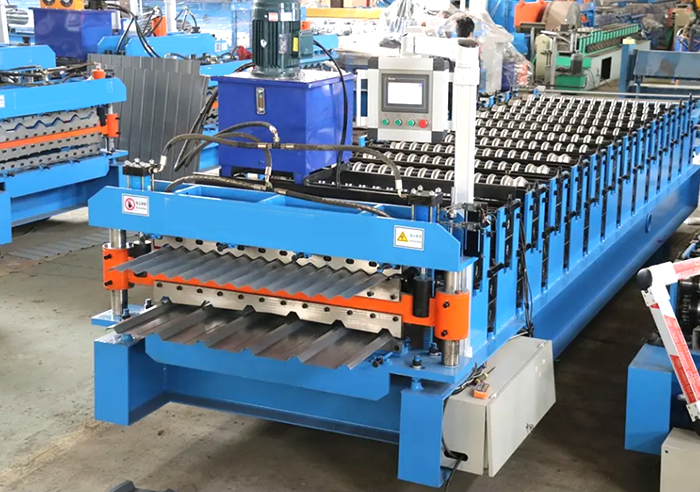

aluminium embossing machine

Aluminium embossing is widely used in various applications. In the construction industry, embossed aluminium panels are often used for decorative façades, providing visual interest while also offering weather resistance. In the automotive sector, embossed aluminium is employed for both aesthetic purposes and functional components, such as heat shields and decorative trim. Furthermore, in the packaging industry, embossed aluminium foil is commonly used for food packaging, providing both protection and an attractive appearance that can enhance brand image.

Sustainability is another important factor driving the use of aluminium embossing machines. Aluminium is 100% recyclable, and embossed products typically require less material due to their enhanced strength and durability. This eco-friendly aspect aligns well with the growing emphasis on sustainable manufacturing practices across various industries.

Moreover, advancements in technology have led to the development of faster and more efficient embossing machines. Today’s machines can quickly produce large volumes of embossed aluminium products, which significantly reduces lead times and operational costs. This efficiency, combined with the ability to create custom designs, allows manufacturers to respond more rapidly to market demands.

In conclusion, aluminium embossing machines offer a multitude of benefits, including precision, enhanced surface properties, and a wide range of applications. Their role in promoting sustainability and efficiency further underscores their importance in modern manufacturing. As technology continues to evolve, the capabilities of these machines will likely expand, paving the way for even more innovative uses of embossed aluminium in the future.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025