Roof Panel Roll Forming Machine for Sale from Leading Manufacturers and Suppliers Worldwide

The Evolution and Benefits of Roof Panel Roll Forming Machines

In the contemporary construction landscape, the demand for efficient and quality roofing solutions has surged. As a result, roof panel roll forming machines have emerged as a pivotal innovation in the manufacturing of roofing materials. These machines are specifically designed to transform flat metal sheets into various profiles of roof panels, catering to the diverse needs of the construction industry.

Understanding Roof Panel Roll Forming Machines

Roof panel roll forming machines are robust industrial machines that utilize a series of rollers to shape metal sheets into desired profiles. The process begins with a flat coil of metal, usually made from materials such as galvanized steel or aluminum. As the coil passes through the series of rollers, it is gradually formed into the specified shape. The precision in this process ensures that the panels are uniform and meet the required specifications, which is crucial for projects demanding high-quality roofing materials.

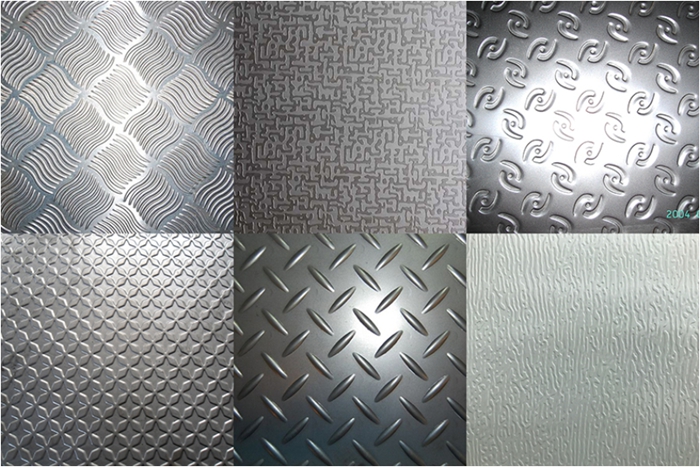

These machines can be customized to produce various profiles, including corrugated sheets, standing seam panels, and tile shapes, among others. The versatility of roof panel roll forming machines allows manufacturers to cater to different architectural styles and customer preferences, ultimately broadening their market reach.

The Advantages of Roof Panel Roll Forming Machines

The use of roof panel roll forming machines offers several significant benefits that contribute to their growing popularity among manufacturers

1. Efficiency and Speed One of the most notable advantages of these machines is their ability to produce roofing panels quickly. With automated systems, manufacturers can produce large volumes of panels in a fraction of the time it would take to create them manually. This efficiency not only saves labor costs but also enables quicker project completion.

roof panel roll forming machine for sale factories

2. Reduced Waste Traditional roofing manufacturing methods often generate substantial material waste. However, roll forming technology minimizes waste by optimizing the use of raw materials. The precise cutting mechanisms and automated setups ensure that each piece is made to exact specifications, leaving minimal leftover material.

3. High-Quality Output The precision engineering involved in roll forming leads to high-quality products that meet stringent industry standards. Each panel produced exhibits uniform thickness, strength, and a clean finish, ensuring durability and aesthetic appeal.

4. Customization Options Many modern roof panel roll forming machines offer customizable features. Manufacturers can adjust parameters such as width, shape, and profile type to meet specific project requirements. This adaptability allows businesses to respond swiftly to market demands and client preferences.

5. Cost-Effectiveness Though the initial investment in a roof panel roll forming machine may seem high, the long-term savings are significant. With reduced labor costs, minimal waste, and enhanced production capabilities, manufacturers can achieve a healthy return on investment over time.

6. Eco-Friendly Production With the construction industry increasingly leaning towards sustainable practices, roof panel roll forming machines fit the bill. By utilizing recyclable materials and reducing waste, these machines support eco-friendly manufacturing processes.

The Market for Roof Panel Roll Forming Machines

As the global construction market continues to expand, so does the demand for roof panel roll forming machines. Factories specializing in these machines are sprouting up, offering a variety of models that cater to both large-scale industrial requirements and smaller enterprises. With advancements in technology, the emphasis is now on machines that are user-friendly, energy-efficient, and capable of producing high-value outputs.

In conclusion, roof panel roll forming machines represent a significant advancement in roofing material production. Their efficiency, reduced waste, and ability to produce high-quality customized products make them indispensable in the construction industry. As the market for these machines grows, manufacturers are poised to keep up with demand while adhering to sustainability practices, ensuring that they remain at the forefront of the architectural landscape. The future of roofing solutions looks bright, driven by innovation and efficiency in manufacturing processes.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025