Top Rollforming Companies Leading the Industry with Innovative Solutions and Products

The Role and Impact of Rollforming Companies in Modern Manufacturing

Rollforming companies play a crucial role in the manufacturing sector, specializing in the production of continuous lengths of metal products. Utilizing a process known as roll forming, these companies take flat sheets of metal and, through a series of sequentially arranged rollers, convert them into various shapes and profiles necessary for diverse applications. This article explores the significance, processes, and innovations associated with rollforming companies in contemporary manufacturing.

Understanding the Rollforming Process

At the heart of rollforming is a process that allows for the efficient transformation of raw materials into finished products. The process begins with the feeding of flat sheet metal through a series of rollers, each designed to progressively shape the material. As the metal passes through each roller station, it is gradually bent and formed into the desired profile. This method offers several advantages over traditional metal forming techniques, including reduced material waste, enhanced efficiency, and the ability to produce complex shapes.

Rollforming is particularly suited for high-volume production runs, where consistency and precision are paramount. The process can accommodate various materials including steel, aluminum, and even plastics, making it versatile for different industries. Once shaped, the metal can be further processed, including cutting, welding, and finishing, to meet specific customer requirements.

Applications Across Industries

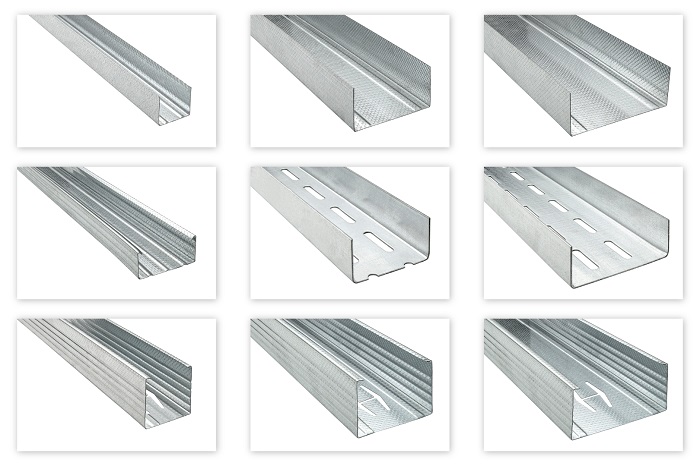

Rollforming companies cater to a broad spectrum of industries, each with unique requirements for metal components. The construction sector is one of the largest consumers of rollformed products. Companies produce metal roofing, wall panels, and framing systems that form the backbone of modern structures. These components are not only strong and durable but also lightweight, contributing to energy efficiency and cost-effectiveness in construction.

In the automotive industry, rollformed parts are used in vehicle chassis, roof frames, and reinforcements, where strength and precision are critical for safety and performance. Additionally, rollformed components are integral to the fabrication of HVAC systems, wherein ductwork and ventilation panels are manufactured to exact specifications.

rollformers companies

With the rise of renewable energy, rollforming companies have also entered the solar energy market, producing frames for solar panels. These components need to withstand environmental stresses while offering longevity and stability, showcasing the adaptability of rollforming technology to evolving industry needs.

Innovations and Advancements

As technology advances, rollforming companies are continuously innovating to enhance their processes and products. Automation plays a significant role in this evolution, with advanced machinery and robotics streamlining production. Automated systems reduce human error, increase production speeds, and enable real-time quality control, ensuring that the final products meet stringent industry standards.

Moreover, the integration of computer-aided design (CAD) and computer numerical control (CNC) systems into the rollforming process allows for greater customization. Clients can now specify advanced designs, and the rollforming equipment can quickly adjust to produce varied shapes and sizes without needing extensive retooling.

Sustainability is another critical consideration as rollforming companies seek to adopt more environmentally friendly practices. Metal recycling is an integral aspect of many rollforming operations, as companies strive to minimize waste and reduce their carbon footprint. By using recycled materials in production, these companies contribute to a circular economy and reduce reliance on virgin materials.

Conclusion

Rollforming companies are essential contributors to the modern manufacturing landscape, providing innovative solutions that meet the demands of various industries. Their ability to efficiently produce high-quality metal components has a significant impact on construction, automotive, and renewable energy sectors, among others. As advancements in technology continue to push the boundaries of what is possible in manufacturing, rollforming companies are well-positioned to adapt and thrive, ensuring they remain at the forefront of industry innovation. The combination of precision engineering, automation, and sustainability will likely define the future of rollforming, making it a critical player in the global manufacturing arena.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025