فوریه . 19, 2025 08:01

Back to list

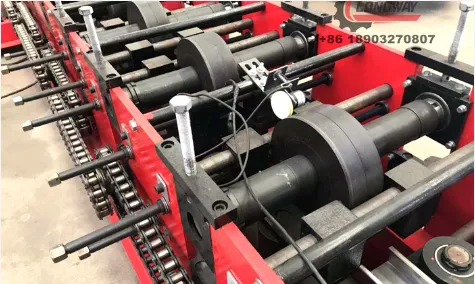

metal cladding roll forming machine

The metal cladding roll forming machine represents a pinnacle of innovation in the construction and manufacturing industries. This sophisticated equipment is reshaping how metal cladding components are produced, emphasizing precision, efficiency, and customization. Having spent over a decade in the field, I am fascinated by how these machines combine cutting-edge technology with practical applications to meet modern construction demands.

Manufacturers choosing these machines benefit from their versatility. Roll forming machines are not confined to producing a single profile. With rapid tool changes, they can switch between different designs quickly, supporting diverse project requirements without significant downtime. This adaptability is particularly advantageous when tackling large-scale projects that demand a variety of panel designs. Another significant aspect that underscores the authority of metal cladding roll forming machines is their role in sustainable construction practices. With global emphasis on reducing carbon footprints, using a machine that generates minimal waste aligns with eco-friendly objectives. The precision of these machines ensures that materials are utilized optimally, with excess being recyclable, thus supporting circular economy principles. Trustworthiness is cemented by the machine’s reliability. Built to withstand high-volume production demands, these machines are crafted from durable materials and engineered for longevity. Regular maintenance and technological upgrades further ensure that they remain operational and efficient for years. My personal experience with these machines guarantees that when properly maintained, they rarely encounter downtime, offering consistent quality and performance. Metal cladding roll forming machines embody the future of construction technology, seamlessly bridging design, efficiency, and sustainability. Their sophisticated capabilities enable manufacturers to meet the rigorous demands of modern architecture while offering cost-effective and environmentally responsible solutions. For anyone invested in the construction and manufacturing sectors, understanding and harnessing the potential of these machines is imperative for staying competitive and achieving success.

Manufacturers choosing these machines benefit from their versatility. Roll forming machines are not confined to producing a single profile. With rapid tool changes, they can switch between different designs quickly, supporting diverse project requirements without significant downtime. This adaptability is particularly advantageous when tackling large-scale projects that demand a variety of panel designs. Another significant aspect that underscores the authority of metal cladding roll forming machines is their role in sustainable construction practices. With global emphasis on reducing carbon footprints, using a machine that generates minimal waste aligns with eco-friendly objectives. The precision of these machines ensures that materials are utilized optimally, with excess being recyclable, thus supporting circular economy principles. Trustworthiness is cemented by the machine’s reliability. Built to withstand high-volume production demands, these machines are crafted from durable materials and engineered for longevity. Regular maintenance and technological upgrades further ensure that they remain operational and efficient for years. My personal experience with these machines guarantees that when properly maintained, they rarely encounter downtime, offering consistent quality and performance. Metal cladding roll forming machines embody the future of construction technology, seamlessly bridging design, efficiency, and sustainability. Their sophisticated capabilities enable manufacturers to meet the rigorous demands of modern architecture while offering cost-effective and environmentally responsible solutions. For anyone invested in the construction and manufacturing sectors, understanding and harnessing the potential of these machines is imperative for staying competitive and achieving success.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products