Innovative Roof Truss Press Machine Solutions for Efficient Construction Industry Applications

The Importance of Roof Truss Press Machines in Modern Construction

In the ever-evolving world of construction and architecture, the efficiency and quality of structural components play a significant role in the success of any project. One critical component in many building frameworks is the roof truss. Roof trusses provide support and stability to roofs, and their design and construction require precision engineering and manufacturing processes. This is where roof truss press machines come into play, facilitating the production of high-quality trusses in a timely and cost-effective manner.

A roof truss press machine is a specialized piece of equipment used to manufacture roof trusses from various materials, such as wood and metal. These machines streamline the truss fabrication process, enabling manufacturers to produce custom trusses that meet specific design requirements. The use of advanced technology in these machines ensures that trusses are not only built to specification but also that they conform to relevant building codes and standards.

How Roof Truss Press Machines Work

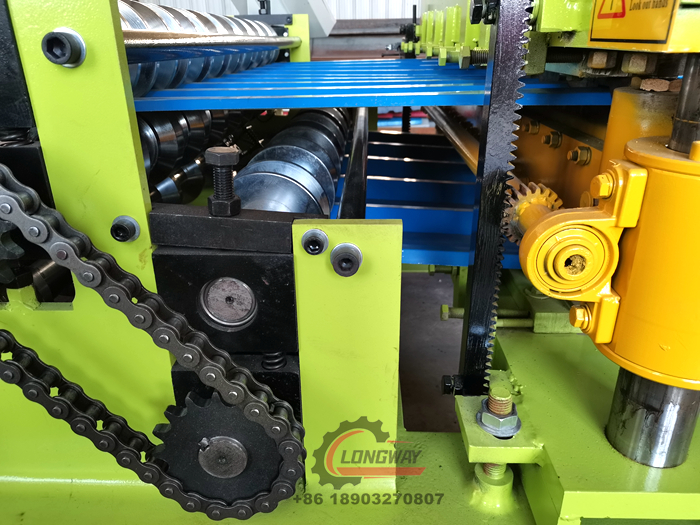

Roof truss press machines operate by utilizing hydraulic or mechanical pressing systems to assemble truss components. The process typically begins with the collection of raw materials, which are then cut and shaped into the necessary parts of the truss.

Once the components are prepared, they are placed in the machine, where the pressing mechanism precisely positions and secures them together. The use of computer-aided design (CAD) software further enhances the accuracy of the assembly by allowing manufacturers to create detailed plans and patterns for the trusses.

This automation not only increases the speed of production but also reduces the risk of human error. As a result, roof truss press machines contribute to improved overall quality in truss manufacturing, leading to more durable and reliable structures in the long run.

Benefits of Using Roof Truss Press Machines

roof truss press machine company

The adoption of roof truss press machines offers several advantages for construction companies and manufacturers. Firstly, these machines significantly enhance productivity. Instead of relying on manual labor, which can be slow and prone to errors, automated press machines can produce large quantities of trusses in a fraction of the time.

Secondly, the precision with which trusses are manufactured using these machines reduces waste. Accurate measurements and consistent quality mean that fewer materials are discarded due to defects or mistakes, saving both time and resources.

Moreover, the use of roof truss press machines leads to cost savings for construction companies. By decreasing labor costs and minimizing material waste, these machines allow companies to bid more competitively on projects. In a sector where margins can be tight, the ability to produce cost-effective solutions is vital for success.

The Future of Roof Truss Manufacturing

As technology continues to advance, the roof truss press machine industry is poised for further innovation. Developments in automation, artificial intelligence, and materials science hold the promise of even more efficient production processes. For example, the integration of robotics and machine learning could optimize manufacturing workflows, further reducing the time and costs involved in truss production.

Sustainability is also becoming increasingly important in construction. Future roof truss press machines may utilize eco-friendly materials and manufacturing methods, aligning with the industry’s push towards greener practices.

Conclusion

In conclusion, roof truss press machines are indispensable tools in the modern construction landscape. They not only improve the quality and efficiency of roof truss production but also contribute to significant cost savings and sustainability in building practices. As the construction industry continues to evolve, these machines will undoubtedly play a pivotal role in shaping the future of architectural design and structural integrity. Investing in advanced roof truss press technology is not just a step towards operational efficiency; it's a strategic move towards leading the market in a competitive industry.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025