c z purlin roll forming machine manufacturers

The Importance of C Z Purlin Roll Forming Machines in Construction and Manufacturing

In the realm of construction and manufacturing, the efficiency and accuracy of the components used are critical to project success. One such component is the purlin, which plays a key role in providing structural support for various types of buildings, from warehouses to agricultural structures. The demand for high-quality, durable purlins has led to the emergence of specialized machinery, with C Z purlin roll forming machines at the forefront of this evolution.

C Z purlins are widely used due to their strength-to-weight ratio and versatility. They are available in various shapes, with the “C” and “Z” shapes being the most commonly utilized. These profiles provide excellent support for roofing and wall systems, making them a staple in the steel structure industry. The roll forming process transforms flat metal sheets into these complex shapes with minimal waste, thus becoming an essential part of the manufacturing workflow.

The operation of a C Z purlin roll forming machine involves feeding metal coils through a series of rolls that gradually shape them into the desired profile. This machine can be adjusted to produce different sizes and thicknesses of purlins, providing manufacturers with the flexibility to meet varying project specifications. Given the advantages of speed and precision in the roll forming process, businesses can enhance their production efficiency and reduce lead times, which is crucial in today’s fast-paced construction environment.

One of the key advantages of using C Z purlin roll forming machines is the ability to produce custom orders. Manufacturers can create purlins tailored to specific requirements, ensuring compatibility with various building designs. This customization capability allows for innovative architectural trends to be accommodated, further driving demand for these machines.

c z purlin roll forming machine manufacturers

Moreover, manufacturers of C Z purlin roll forming machines are increasingly incorporating advanced technology into their designs. Automation, computerized controls, and energy-efficient systems are becoming standard, enabling better monitoring of the production process. These technological advancements not only enhance the precision of the purlin profiles but also improve overall safety and reduce labor costs.

In addition to technological advancements, there is a growing emphasis on sustainable practices in the manufacturing sector. C Z purlin roll forming machines contribute to sustainability by minimizing material waste and allowing for the reuse of offcuts. Manufacturers are also increasingly using recyclable materials, aligning with global efforts to reduce the environmental impact of construction activities.

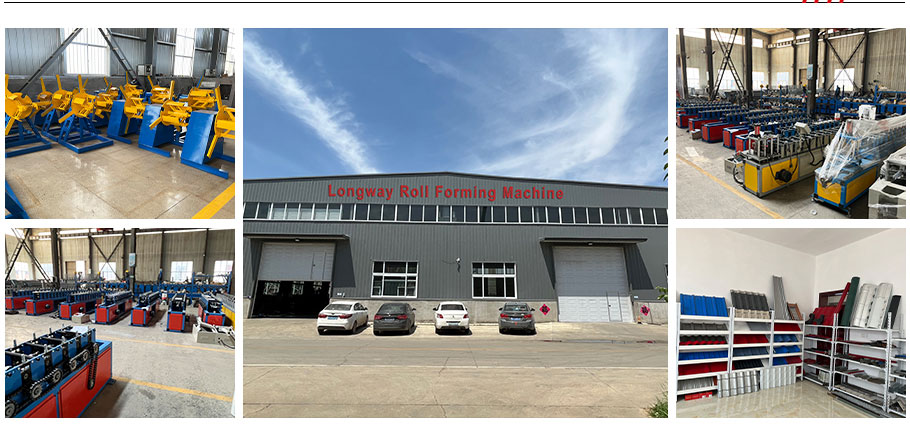

When choosing a C Z purlin roll forming machine manufacturer, it is essential to consider factors such as the technology employed, the machine’s flexibility, production capacity, and after-sales support. Established manufacturers often provide comprehensive training and service packages, ensuring that clients can operate the machines efficiently and maintain them over time.

In conclusion, C Z purlin roll forming machines play a vital role in modern construction and manufacturing practices. Their ability to produce high-quality, customized purlins efficiently aligns with the evolving demands of the industry. As technology continues to progress, these machines will undoubtedly play an integral part in shaping the future of structural engineering and construction methodologies.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025