cheap metalcon montante roll forming machine

The Cost-Effectiveness of Cheap Metal Con Montante Roll Forming Machines

In an era where efficiency and cost-effectiveness dominate manufacturing processes, the development and use of roll forming technology have become increasingly vital. Among the various machines designed for forming metal components, the cheap metal con montante roll forming machine stands out not only for its affordability but also for its efficiency, versatility, and ease of use. Understanding its features and the benefits it brings to industry can help businesses make informed decisions regarding production strategies.

Understanding Roll Forming Technology

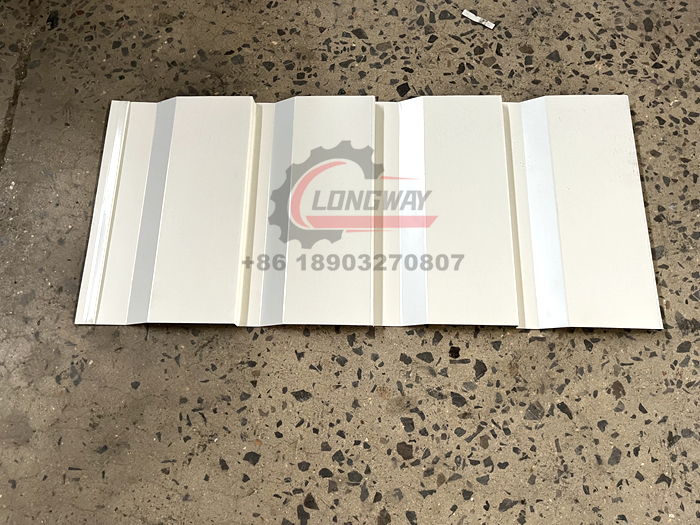

Roll forming is a continuous bending operation in which a long strip of metal is passed through successive pairs of rolls to create the desired cross-section profile. This process is particularly suitable for producing lightweight yet strong profiles used in various applications. The cheap metal con montante roll forming machine is designed specifically for forming vertical metal components, commonly referred to as montantes in construction, which serve as critical structural elements in framing systems for walls, roofs, and commercial buildings.

Key Features of Cheap Metal Con Montante Roll Forming Machines

1. Affordability As indicated by its name, the cheap metal con montante roll forming machine is budget-friendly, making it an ideal choice for small to medium-sized enterprises (SMEs) looking to enhance their production capabilities without incurring heavy investments.

2. High Efficiency These machines can produce large quantities of metal profiles at a high speed. The continuous flow of production minimizes cycle times, thus maximizing output and reducing labor costs.

3. Versatility The cheap metal con montante roll forming machine can accommodate a variety of metals, including galvanized steel, stainless steel, and aluminum. This versatility allows businesses to cater to different client needs and adapt to market demands swiftly.

4. Precision and Quality With advanced design and engineering, these machines offer high precision in the forming process, resulting in consistent quality across all produced components. High-quality profiles minimize waste and reduce the need for secondary processes.

cheap metalcon montante roll forming machine

5. Ease of Operation Modern roll forming machines come equipped with user-friendly controls and systems, requiring minimal training for operators. This feature reduces the learning curve, allowing production to start quickly and efficiently.

Applications in the Construction Industry

The cheap metal con montante roll forming machine is particularly popular in the construction sector. Montantes are essential in the creation of lightweight steel frames, which are increasingly used in modern building projects due to their strength and ease of installation. These frames not only provide structural support but also contribute to energy efficiency when combined with appropriate insulating materials.

Additionally, roll-formed montantes are used in a variety of applications, from residential buildings to commercial structures. Their lightweight properties allow for faster construction times and reduced labor costs, making them an attractive choice for contractors looking to optimize project timelines and budgets.

Long-term Operational Benefits

Investing in a cheap metal con montante roll forming machine can yield significant long-term benefits. By streamlining the manufacturing process, businesses can reduce lead times and enhance their responsiveness to market changes. Moreover, the ability to produce high-quality components consistently helps to establish a strong reputation in the industry, attracting more clients and projects.

Additionally, with the continuous advancements in roll forming technology, newer models are often designed with energy-efficient features. This not only contributes to sustainability but also helps to decrease operational costs in the long run.

Conclusion

The cheap metal con montante roll forming machine exemplifies the intersection of affordability and efficiency in metalworking. With its unique features and advantages tailored for the construction industry, it emerges as a beneficial investment for businesses aiming to enhance their operational capabilities. As the demand for lightweight and durable construction solutions continues to grow, adopting such technology could very well position businesses at the forefront of innovation in the marketplace. Understanding and leveraging the potential of these machines can be a game-changer for manufacturers, bringing about significant improvements in productivity, cost management, and overall business success.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025