channel roll forming machine factory

Channel Roll Forming Machine Factory An Overview

In recent years, the construction and manufacturing industries have witnessed a significant transformation, primarily driven by technological advancements. One crucial piece of equipment that has revolutionized metal fabrication is the channel roll forming machine. This specialized machinery allows manufacturers to produce high-quality channel sections efficiently and accurately. In this article, we will delve into the significance of channel roll forming machines, the production processes involved, and the role of factories in delivering these essential machines.

Understanding Channel Roll Forming Machines

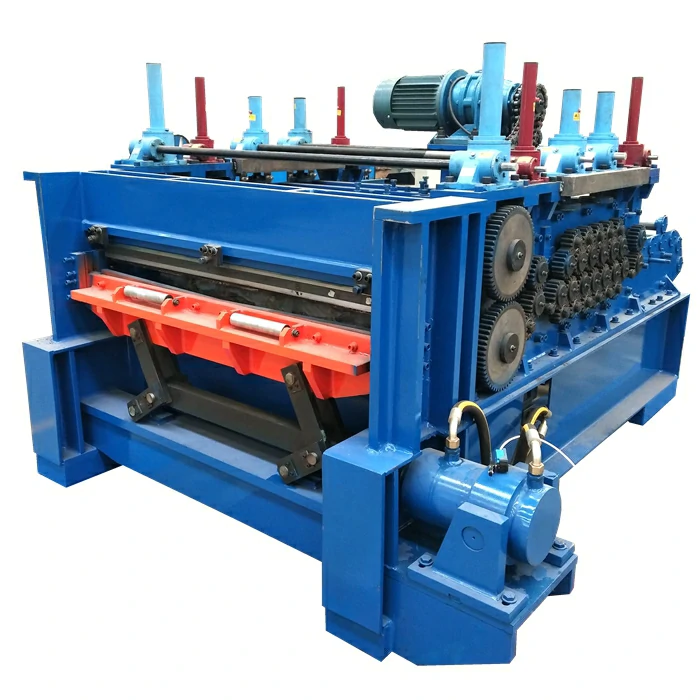

Channel roll forming machines are specialized pieces of equipment designed to transform flat metal strips into U-shaped channel sections. These sections are widely used in a variety of applications, from building structures to furniture production. The roll forming process involves feeding a continuous strip of metal through a series of rollers configured to gradually shape the metal into the desired channel form. The precision and consistency achievable through this process make it an essential tool for manufacturers.

Beyond shaping, channel roll forming machines can also be equipped with additional features such as punching, cutting, and bending capabilities. These integrated functions allow manufacturers to streamline their production processes, reducing both time and labor costs while increasing efficiency.

The Production Process

The production process of channel roll forming machines involves several key steps, from design and engineering to manufacturing and quality control

.1. Design and Engineering The process begins with an understanding of the specific requirements of the end product. Engineers will design the roll forming machine to accommodate various channel sizes and specifications, ensuring that it meets industry standards.

channel roll forming machine factory

2. Manufacturing Once the design is finalized, the manufacturing of the machine components begins. High-quality raw materials such as steel are used to ensure durability and reliability. Advanced CNC machining technologies are often utilized to fabricate precision parts for the machine.

3. Assembly After the individual components are manufactured, they are assembled into a complete channel roll forming machine. During this phase, careful attention is given to ensure that all components fit perfectly and function as intended.

4. Quality Control Before the machines are shipped to customers, rigorous quality control tests are conducted. This includes checking the dimensional accuracy of the channel sections produced, inspecting the machine's performance, and ensuring that it meets safety standards.

The Role of Factories

Channel roll forming machine factories play a critical role in the supply chain of manufacturing equipment. These factories not only produce machines but also provide essential support to their clients. They offer technical assistance, training, and maintenance services to ensure that customers can achieve optimal performance from their machines.

Additionally, many factories are embracing Industry 4.0 practices, incorporating automation and data analytics into their operations. This shift allows for greater efficiency in production processes and enhances the ability to respond swiftly to market demands. By utilizing cutting-edge technologies such as IoT devices and machine learning, factories can monitor machine performance in real-time, predict maintenance needs, and optimize production schedules.

Conclusion

The channel roll forming machine has become an indispensable tool in the metal fabrication industry. With their ability to produce high-quality channel sections efficiently, these machines are essential for various applications across multiple sectors. As factories continue to innovate and improve their manufacturing processes, the availability and capabilities of channel roll forming machines will likely expand, further enhancing productivity in the modern manufacturing landscape. As the demand for robust and reliable construction materials grows, so will the significance of channel roll forming machines in meeting industry needs.