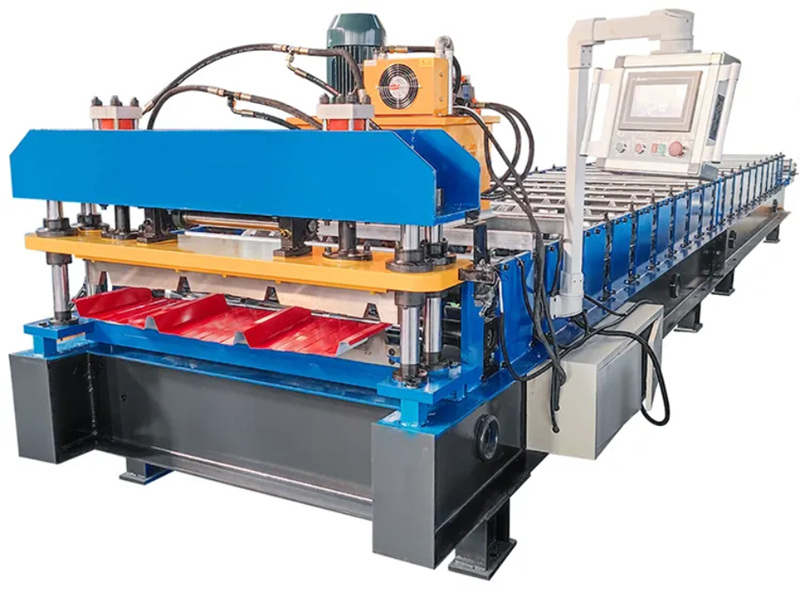

aluminium roll forming machine china

Aluminium Roll Forming Machines in China A Comprehensive Overview

The demand for aluminium roll forming machines has seen a significant increase in recent years, driven by the rapid growth of industries such as construction, automotive, and aerospace

. China, as a global manufacturing powerhouse, has emerged as a leading producer and supplier of these advanced machines, which are instrumental in transforming aluminium into various shapes and forms for numerous applications.Aluminium roll forming machines are designed to shape continuous strips of aluminium into desired profiles with precision and efficiency. The process involves passing an aluminium coil through a series of rollers, each designed to progressively bend the material into a specific shape. This method is highly efficient, allowing for high-volume production with minimal waste, which is particularly beneficial in a world increasingly focused on sustainability and resource efficiency.

One of the primary reasons for the growing popularity of aluminium roll forming machines in China is the vast array of industries they serve. In the construction sector, these machines are used to produce components such as roofing sheets, wall panels, and window frames that require durability and corrosion resistance. The automotive industry benefits from aluminium roll forming for manufacturing lightweight components that enhance fuel efficiency while maintaining safety standards. Additionally, the aerospace sector utilizes these machines to produce parts that are both lightweight and strong, essential for modern aircraft designs.

aluminium roll forming machine china

China's strength in this field is bolstered by its vast industrial infrastructure and skilled workforce. Chinese manufacturers have adopted advanced technologies and modern production techniques, allowing them to produce high-quality aluminium roll forming machines that cater to both domestic and international markets. Many factories utilize state-of-the-art computer numerical control (CNC) systems to ensure accuracy and consistency in production. Moreover, the implementation of automation in the manufacturing process has reduced labor costs and improved overall efficiency.

Chinese aluminium roll forming machines are known for their versatility, capable of accommodating a wide range of specifications and designs. Customers can select from various configurations, including adjustable roll spacing and the ability to handle different thicknesses of aluminium. This flexibility is crucial for manufacturers looking to create custom products tailored to specific market demands.

Another significant advantage of sourcing aluminium roll forming machines from China is cost-effectiveness. Competitive pricing, coupled with a range of financing options, makes it feasible for companies to invest in advanced equipment without straining their budgets. Additionally, Chinese manufacturers often provide comprehensive after-sales services, including installation, training, and maintenance, to ensure optimal machine performance and customer satisfaction.

In conclusion, the aluminium roll forming machine industry in China is experiencing rapid growth, fueled by the increasing demand for efficient and versatile manufacturing solutions across multiple sectors. With advanced technology, a skilled workforce, and competitive pricing, Chinese manufacturers are well-positioned to meet the global demand for high-quality aluminium products. As industries continue to evolve, the role of aluminium roll forming machines will undoubtedly expand, further solidifying China’s position as a leader in this essential manufacturing domain.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025