step tile roll forming machine factory

Step Tile Roll Forming Machine Factory Pioneering Innovative Solutions

In the world of modern construction and manufacturing, the demand for efficient and versatile production methods has never been higher. Among the array of innovative solutions, the step tile roll forming machine stands out as a critical player in the roofing and architectural industry. This article explores the fundamentals of step tile roll forming machines, their significance in manufacturing, and the advancements that factories are implementing to meet the evolving demands of the market.

Understanding Step Tile Roll Forming Machines

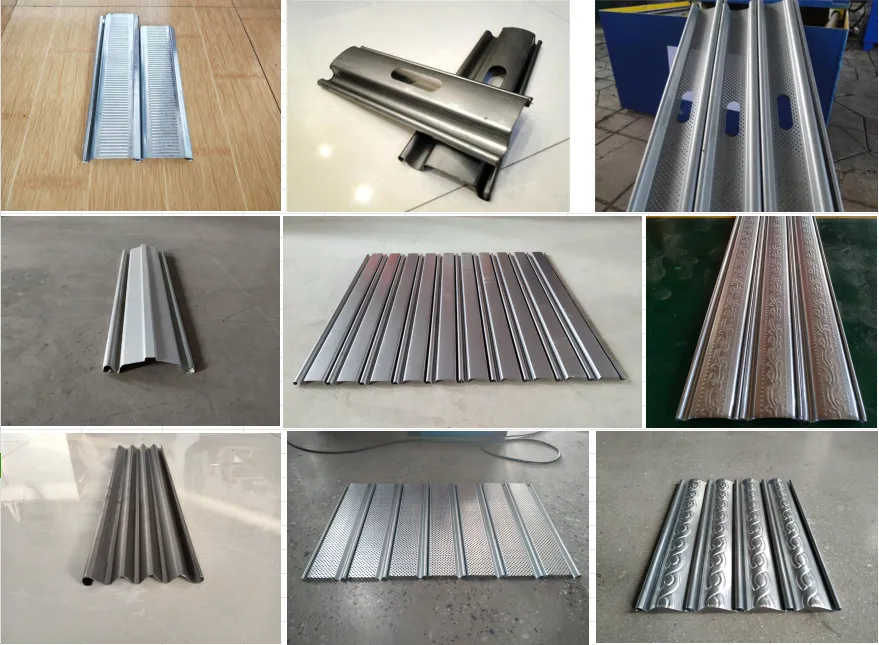

A step tile roll forming machine is an advanced piece of equipment designed to create step tiles that are commonly used in residential and commercial roofing. These machines employ a continuous process that involves feeding metal sheets through a series of rollers, which progressively shape the material into distinct tile profiles. The result is not only aesthetically pleasing but also highly functional, providing durability and protection against adverse weather conditions.

One of the primary advantages of using a step tile roll forming machine is its ability to produce tiles in large quantities with minimal labor. This efficiency is further enhanced by the machine’s precision engineering, which ensures that each tile meets strict quality and dimensional standards. The output can be customized to fit various architectural designs, making it a favored choice among builders and architects alike.

Significance in the Manufacturing Sector

The step tile roll forming machine plays a pivotal role in the manufacturing sector. With the global shift towards sustainable building practices, manufacturers are increasingly looking for methods that reduce waste and energy consumption. The roll forming process minimizes excess material wastage by utilizing a continuous strip of metal, thus aligning with green manufacturing principles.

Moreover, the machines are capable of working with a variety of materials, including galvanized steel, aluminum, and copper, allowing for versatile applications across different projects. This adaptability means that manufacturers can cater to a broader range of customer specifications, thereby enhancing their market competitiveness.

step tile roll forming machine factory

Technological Advancements and Innovations

As technology continues to advance, step tile roll forming machines are also evolving. Modern factories are investing in automated systems that utilize smart technology to enhance production efficiency. Features such as computer numerical control (CNC) systems allow for precise configurations and reduce the likelihood of human error. This level of automation not only speeds up production but also ensures consistent quality in the finished product.

In addition, advancements in materials science have led to the development of stronger and more lightweight materials. This shift provides manufacturers with innovative options that can enhance the durability and lifespan of the tiles produced. Furthermore, coatings that offer resistance to corrosion and fading are also being integrated, improving the overall performance of the roofing solutions.

The Future of Step Tile Roll Forming Machines

Looking ahead, the step tile roll forming machine industry is poised for growth. As urbanization and infrastructure development continue to expand globally, the demand for high-quality roofing solutions will only increase. Factories are expected to further embrace technological advancements, including artificial intelligence and machine learning, to optimize their operations and lead times.

Additionally, as the focus on sustainability grows, manufacturers will be tasked with innovating environmentally friendly production methods. This may include the use of recyclable materials or processes that are less energy-intensive, thereby reducing the overall carbon footprint of production.

Conclusion

In conclusion, the step tile roll forming machine factory embodies the intersection of tradition and innovation. With a strong emphasis on efficiency, quality, and sustainability, these factories are not just manufacturing tiles; they are contributing to the advancement of the construction industry. As technology continues to evolve and customer needs shift, the role of step tile roll forming machines will undoubtedly remain integral in shaping the landscape of modern architecture. The future is bright for manufacturers willing to adapt and innovate in this dynamic market.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025