jan . 17, 2025 04:56

Back to list

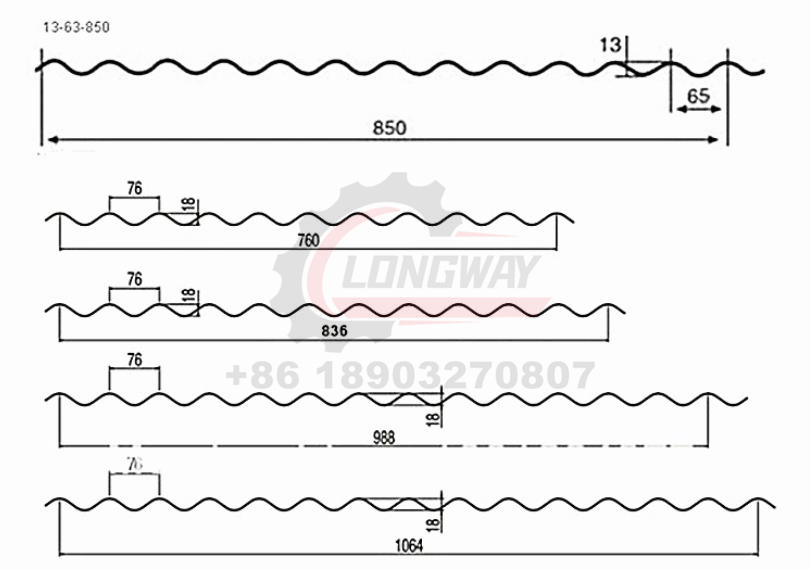

Maquina para panel micro acanalado/ondulado 762/1020

Navigating the world of roof sheet machines requires a blend of experience, expertise, authoritativeness, and trustworthiness to make an informed purchasing decision. A critical aspect of this process is understanding the pricing of these machines—a factor that influences both budget allocations and investment strategies.

The brand of the machine is also a determinant of price. Established brands with a proven track record of reliability and innovation often charge a premium for their products. While opting for a reputable brand may increase initial expenditure, the benefits of quality assurance, superior after-sales service, and warranty options often outweigh the initial cost. Location plays a significant role in pricing variances. Import duties, shipping fees, and local market demand can affect final pricing for international buyers. It becomes essential to consider these additional costs and ensure that they fit within your budgetary framework. An expert evaluation of machine performance specifications is indispensable when contemplating a purchase. Key performance metrics, such as machine speed, sheet thickness capacity, and energy consumption, should be considered alongside price. Buyers should seek machines that offer optimal performance metrics aligned with their production needs, thereby ensuring efficient use of resources and maximizing productivity. Authoritative reviews and testimonials provide credible insights into machine functionality and customer satisfaction. Engaging with industry forums and customer feedback can provide a deeper understanding of cost-to-performance ratios and highlight any potential issues that might arise post-purchase. Establishing a dialogue with current users or industry veterans can also enhance trust in the buying process, backing up the purchase with real-world data and unbiased opinions. In conclusion, while price remains a significant factor in selecting a roof sheet machine, it is essential to balance this with an evaluation of machine type, material quality, brand reputation, and localized costs. By leveraging expert insights and authoritative resources, buyers can make a trustworthy and informed decision, yielding long-term benefits and advanced operational capabilities for their businesses.

The brand of the machine is also a determinant of price. Established brands with a proven track record of reliability and innovation often charge a premium for their products. While opting for a reputable brand may increase initial expenditure, the benefits of quality assurance, superior after-sales service, and warranty options often outweigh the initial cost. Location plays a significant role in pricing variances. Import duties, shipping fees, and local market demand can affect final pricing for international buyers. It becomes essential to consider these additional costs and ensure that they fit within your budgetary framework. An expert evaluation of machine performance specifications is indispensable when contemplating a purchase. Key performance metrics, such as machine speed, sheet thickness capacity, and energy consumption, should be considered alongside price. Buyers should seek machines that offer optimal performance metrics aligned with their production needs, thereby ensuring efficient use of resources and maximizing productivity. Authoritative reviews and testimonials provide credible insights into machine functionality and customer satisfaction. Engaging with industry forums and customer feedback can provide a deeper understanding of cost-to-performance ratios and highlight any potential issues that might arise post-purchase. Establishing a dialogue with current users or industry veterans can also enhance trust in the buying process, backing up the purchase with real-world data and unbiased opinions. In conclusion, while price remains a significant factor in selecting a roof sheet machine, it is essential to balance this with an evaluation of machine type, material quality, brand reputation, and localized costs. By leveraging expert insights and authoritative resources, buyers can make a trustworthy and informed decision, yielding long-term benefits and advanced operational capabilities for their businesses.

Latest news

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025

Related Products