Roofing Sheet Production Equipment Manufacturer for Efficient and High-Quality Results

Roofing Sheet Machine Factory Transforming Sheets into Durable Roofing Solutions

In today's rapidly evolving construction industry, the need for high-quality roofing solutions is paramount. As buildings evolve to embrace both aesthetic appeal and structural integrity, roofing materials play a crucial role in ensuring long-lasting protection against the elements. This is where roofing sheet machine factories come into play. These factories specialize in the production of roofing sheets, transforming raw materials into durable, functional, and aesthetically pleasing products.

The Role of Roofing Sheet Machine Factories

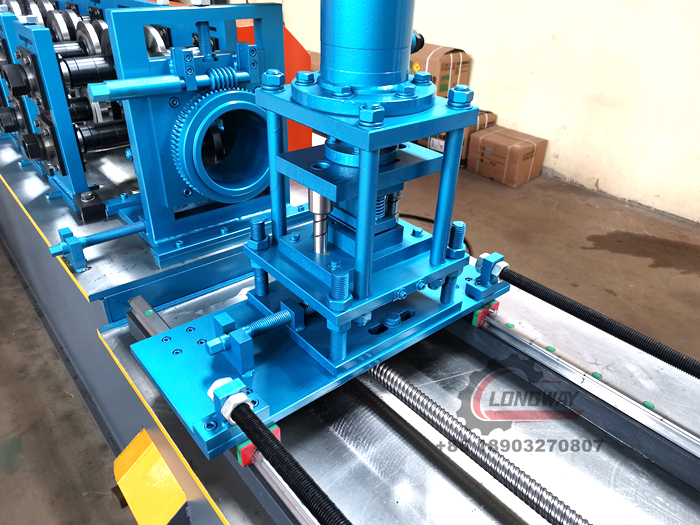

Roofing sheet machine factories are equipped with advanced machinery that allows them to manufacture a variety of roofing sheets tailored to different needs. The process begins with the selection of raw materials, typically galvanized steel, aluminum, or PVC. These materials are then fed into specialized machines that cut, shape, and curl them into the desired roofing profiles. The precision of these machines ensures that each sheet meets industry standards, providing builders and homeowners with reliable roofing solutions.

One of the primary advantages of roofing sheet machines is their ability to produce customized profiles. Different climates and architectural styles require different types of roofing. For instance, a steep-sloped roof may need corrugated sheets for better drainage, while a flat roof might require standing seam sheets for a sleek finish. Roofing sheet machine factories can adjust their manufacturing processes to meet these varying demands, making them a vital resource in the construction industry.

Innovation and Technology in Production

Technological advancement has transformed manufacturing processes across all industries, and roofing sheet production is no exception. Modern roofing sheet machine factories utilize computer numerical control (CNC) technology, ensuring high precision and efficiency in producing roofing sheets. This technology allows for quick adjustments to be made on the fly, which significantly reduces downtime and waste.

Moreover, the introduction of automated systems has streamlined production lines, enhancing productivity. Automated systems not only speed up the manufacturing process but also improve safety by minimizing human involvement in potentially hazardous tasks. The innovation within these factories ensures that the production of roofing sheets is both efficient and safe, providing high-quality products while maintaining a commitment to worker safety.

roofing sheet machine factory

Environmental Considerations

As the world grapples with the impact of climate change, roofing sheet machine factories are also taking steps to adopt more sustainable practices. Many manufacturers are now focusing on using recycled materials in their production processes. By recycling metals and plastics, these factories can significantly reduce waste and lower their carbon footprint.

Additionally, energy-efficient machines are being incorporated into the production line. These machines consume less energy, further contributing to the sustainability of the manufacturing process. Many roofing sheets produced today are designed to be more reflective, which helps minimize heat absorption in buildings, reducing cooling costs and contributing to energy efficiency in the long run.

Market Demand and Future Prospects

The demand for quality roofing solutions has seen a steady increase, driven by the construction of new homes, commercial buildings, and infrastructure projects worldwide. With urbanization on the rise, roofing sheet machine factories are poised to expand their operations to meet this growing demand. As economies continue to develop, the need for durable, low-maintenance roofing materials will remain a priority for builders and homeowners alike.

In addition, the growing interest in sustainable building practices is likely to drive the adoption of eco-friendly roofing materials. Roofing sheet machine factories that innovate and adapt to these trends stand to gain a competitive edge in the market.

Conclusion

Roofing sheet machine factories are essential players in the construction industry, providing high-quality roofing solutions that meet a diverse range of architectural needs. Through advanced technology, sustainable practices, and a commitment to customization, these factories significantly contribute to the durability and aesthetics of buildings. As the demand for innovative and sustainable building materials continues to grow, roofing sheet machine factories will undoubtedly play a pivotal role in shaping the future of construction. Their commitment to quality and innovation ensures that they remain at the forefront of this essential industry, helping to protect homes and businesses for generations to come.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025