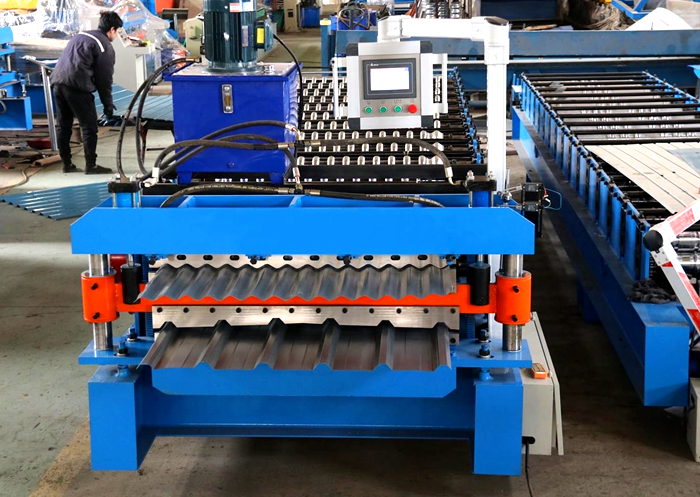

Roll Forming Machine Featuring Integrated Hole Punching System for Enhanced Efficiency and Versatility

Roll Forming Machines with Hole Punching An Overview

Roll forming is a continuous bending operation in which a long strip of metal is passed through a series of rollers to achieve the desired cross-section. This process is widely utilized in various industries, including automotive, construction, and appliance manufacturing. One remarkable enhancement to traditional roll forming is the integration of hole punching capabilities. This combination not only optimizes production efficiency but also enhances the versatility of the produced parts.

Roll Forming Machines with Hole Punching An Overview

Using a roll forming machine equipped with a hole punching feature has numerous advantages. First and foremost, it allows for precise control over the hole dimensions and locations, resulting in high-quality end products that meet strict specifications. With advanced digital controls, operators can adjust the size and position of the holes as needed, accommodating various design requirements without the need for extensive retooling. This flexibility is particularly advantageous in today’s fast-paced manufacturing environment, where customization is often paramount.

roll forming machine with hole punching

Additionally, the integration of hole punching into the roll forming process leads to a more efficient use of materials. By punching holes during the rolling operation, manufacturers can minimize waste considerably. Traditional methods often involve cutting out sections of metal for punching, leading to significant scrap material. In contrast, the roll forming with hole punching approach allows manufacturers to make better use of the original material, ultimately reducing costs and environmental impact.

Moreover, the durability and efficiency of roll forming machines equipped with hole punching mechanisms are noteworthy. Modern machines utilize high-strength materials and cutting-edge technology, resulting in long-lasting equipment that can withstand rigorous production demands. This durability translates into less downtime and maintenance, which further boosts productivity. Operators also benefit from simplified workflows, as the need for separate punching equipment is reduced or eliminated altogether.

In conclusion, roll forming machines with hole punching capabilities represent a significant advancement in metal processing technology. By combining forming and punching operations into a single process, manufacturers can achieve greater efficiency, reduced waste, and enhanced product quality. As industries continue to evolve and demand more innovative solutions, the adoption of such advanced machinery will only increase. The versatility and efficiency of roll forming machines equipped with hole punching not only meet the current market needs but also pave the way for future advancements in manufacturing technology.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025