Metal Roof Ridge Cap Roll Forming Machine Manufacturer for High-Quality Roofing Solutions

Understanding Metal Roof Ridge Cap Roll Forming Machines

In the modern construction and architectural landscape, roofing materials have evolved significantly, leading to the popularity of metal roofing solutions. Among the various components that ensure the structural integrity and aesthetic appeal of a metal roof, the ridge cap is perhaps one of the most crucial. This is where the metal roof ridge cap roll forming machine comes into play, representing a vital innovation in the way roofing materials are manufactured.

What is a Metal Roof Ridge Cap?

A ridge cap is a finishing piece that covers the top edge of a roof, where two slopes meet. Its primary functions include preventing water from entering a building, enhancing durability against weather conditions, and providing a polished look to the overall design. Metal ridge caps are favored due to their longevity, resistance to rust and corrosion, and ability to withstand extreme weather elements.

The Role of Ridge Cap Roll Forming Machines

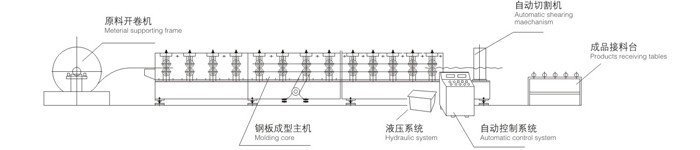

Roll forming is a high-efficiency manufacturing process that transforms metal sheets into specific profiles through the application of continuous bending. A metal roof ridge cap roll forming machine is designed specifically to produce ridge caps with precision and consistency. These machines can create various designs, ensuring compatibility with different roofing styles while adhering to industry standards.

The Process of Roll Forming

The roll forming process begins with a flat metal sheet, usually made of steel or aluminum. The sheet is fed into the machine, where it passes through a series of rollers. Each roller incrementally shapes the metal, bending it to match the desired profile of the ridge cap. This continuous process allows for the production of long sections of ridge caps, which can be cut to length as required. The benefits of this method include reduced waste, increased efficiency, and the capability to create custom designs for specific projects.

Key Features of a Roll Forming Machine

1. Automation and Control Modern metal roof ridge cap roll forming machines are equipped with advanced CNC (Computer Numerical Control) systems. This technology enables precise control of the shaping process, ensuring consistent quality across each unit produced.

metal roof ridge cap roll forming machine factory

2. Speed and Efficiency Roll forming machines can produce high volumes of ridge caps in a shorter amount of time compared to traditional manufacturing methods. This rapid production capability is essential for meeting the demands of large construction projects.

3. Versatility in Design These machines can be adjusted to create various profiles, allowing manufacturers to cater to a wide range of architectural styles. This versatility is crucial for roofing suppliers who aim to offer diverse product lines.

4. Durability Built with robust materials, metal roof ridge cap roll forming machines are designed to withstand prolonged use, making them highly durable and reliable investments for manufacturing facilities.

5. Reliability and Maintenance Many machines come with easy-to-follow maintenance guidelines, ensuring they remain in optimal condition. This dependability is vital for maintaining production schedules and minimizing downtime.

Selecting the Right Machine

When considering investing in a metal roof ridge cap roll forming machine, several factors should be taken into account

- Output Capacity Assess the expected production volume to choose a machine that can meet that demand without compromising quality. - Customizability Look for machines that offer flexibility in design alterations, accommodating various ridge cap styles. - Quality of Components Ensure the machine is constructed from high-quality materials to guarantee longevity and consistent performance. - Vendor Reputation Research potential manufacturers or suppliers. A reputable vendor will provide support and service, ensuring your machine performs optimally.

Conclusion

The metal roof ridge cap roll forming machine is an essential piece of equipment in the roofing industry. It not only enhances the efficiency and quality of ridge cap production but also contributes to the overall sustainability of construction practices through reduced waste and increased durability of roofing materials. As the industry continues to evolve, investing in advanced manufacturing technologies like roll forming machines will be paramount for staying competitive and meeting the dynamic needs of construction projects. Whether you are a contractor, builder, or manufacturer, understanding the capabilities and benefits of these machines will empower you to make informed decisions that enhance your operations and service offerings.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025