Top Manufacturers of Metal Roof Cutting Machines for Efficient and Precise Solutions

The Evolution and Significance of Metal Roof Cutting Machines in Manufacturing

In the realm of construction and manufacturing, efficiency and precision are paramount. As the demand for metal roofing solutions continues to grow, the need for specialized equipment, such as metal roof cutting machines, has skyrocketed. These machines play a crucial role in manufacturing processes, providing both speed and accuracy to meet the needs of builders and architects alike. This article explores the evolution of metal roof cutting machines and their significance in today's construction industry.

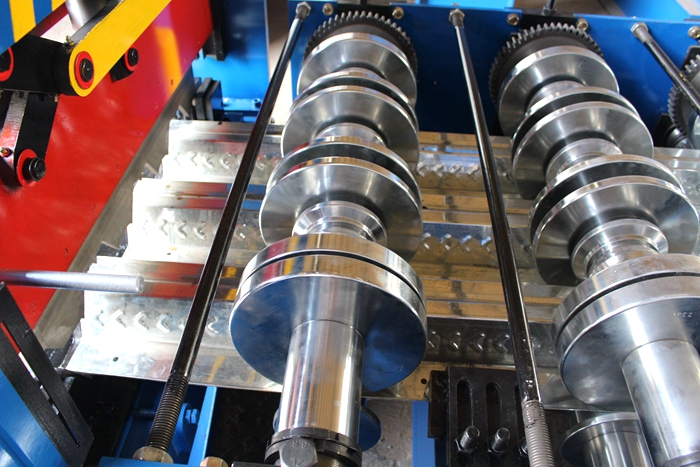

Understanding Metal Roof Cutting Machines

Metal roof cutting machines are specialized tools designed to cut metal sheets into precise shapes and sizes required for roofing applications. These machines come in various forms, including manual and automated systems, each tailored to specific operational needs. The evolution of technology has led to the development of advanced, programmable machines that ensure consistent results while minimizing material waste.

One of the primary advantages of using metal roof cutting machines is their accuracy. Traditional methods of cutting metal sheets often resulted in uneven edges and wasted materials. In contrast, modern cutting machines utilize CNC (Computer Numerical Control) technology, allowing for intricate designs and precise dimensions with minimal human intervention. This technological advancement not only improves efficiency but also enhances the overall quality of the final product.

The Role of Manufacturers

With the increasing demand for these machines, the number of metal roof cutting machine manufacturers has surged. These manufacturers are constantly innovating to meet the evolving requirements of the construction industry. By incorporating features such as speed control, adjustable cutting depths, and user-friendly interfaces, manufacturers are making it easier for workers to operate these machines effectively.

Moreover, manufacturers are also focusing on sustainability. Many cutting machines are now designed to minimize waste, making them environmentally friendly. The push for sustainability in construction means that builders are more inclined to invest in machines that align with eco-friendly practices, further driving the market for efficient metal roof cutting equipment.

Key Features to Consider

metal roof cutting machine manufacturers

When choosing a metal roof cutting machine, several crucial features should be considered

1. Cutting Thickness Different projects require varying thicknesses of metal. It’s essential to select a machine capable of handling the specific thickness needed for your applications.

2. Speed and Efficiency Faster cutting speeds can significantly reduce production time, leading to increased output. Consider machines that offer adjustable speed settings for flexibility.

3. Safety Features Safety should always be a priority in manufacturing. Look for machines that come equipped with essential safety features to protect operators during use.

4. Durability High-quality materials and robust construction design will ensure that the machine withstands prolonged use and remains reliable over time.

5. After-Sales Support Consider manufacturers that offer excellent after-sales support, including training, maintenance, and readily available spare parts.

Conclusion

The importance of metal roof cutting machines cannot be overstated in today's fast-paced construction environment. As technology continues to advance, manufacturers must keep innovating to meet the demands for precision, speed, and sustainability. Investing in high-quality metal roof cutting machines can not only enhance production efficiency but also lead to better quality roofing solutions. For architects, builders, and contractors, understanding the features and benefits of these machines is essential for making informed decisions that positively impact their projects—and ultimately, their bottom line. As the construction industry evolves, so too will the tools that shape its future.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025