feb . 16, 2025 14:53

Back to list

door & window section roll forming machine

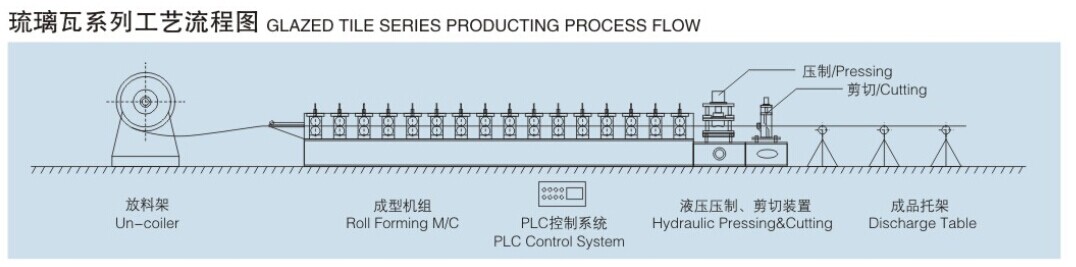

In the realm of industrial manufacturing, the door and window section roll forming machine stands as an indispensable piece of equipment. This sophisticated machinery is designed to efficiently shape metal sheets into desired profiles used extensively in the construction and architectural sectors. Its prowess in delivering precision-crafted components gives it a pivotal role in modern building solutions.

Authoritative voices in the industry consistently highlight the role played by roll forming machines in advancing construction methodologies. Their ability to produce customizable profiles means architects and builders are not constrained by off-the-shelf products, allowing design creativity and innovation to flourish. This capability is paramount in modern architecture where bespoke solutions are often required to meet aesthetic and functional demands. Trustworthiness, a cornerstone of reliable machinery, is another critical aspect of these machines. Reputable manufacturers of door and window section roll forming machines invest heavily in research and development, ensuring their products not only comply with international safety standards but also exceed them. These machines are subjected to rigorous quality assurance tests to corroborate their durability and performance under varying operational conditions. Such due diligence provides confidence to buyers, knowing that their investment is safeguarded by comprehensive warranties and widespread service support networks. Direct interactions with industry professionals reinforce the perception of roll forming machines as investment assets. Testimonials from satisfied users espouse their transformative impact on production capabilities, while case studies highlight significant improvements in output quality and reductions in operational costs. These endorsements amplify the trust placed in these machines and underscore their value proposition. In conclusion, the door and window section roll forming machine stands as an exemplar of industrial evolution. Its integration of advanced technology, versatile functionality, and cost-efficiency builds a compelling case for its indispensability in modern construction. Through experience, expertise, authoritativeness, and trustworthiness, it holds the promise of transforming manufacturing processes, delivering products that align with both contemporary and future demands. As industries advance, the role of such machinery will undoubtedly continue to expand, crafting the frameworks for tomorrow’s world.

Authoritative voices in the industry consistently highlight the role played by roll forming machines in advancing construction methodologies. Their ability to produce customizable profiles means architects and builders are not constrained by off-the-shelf products, allowing design creativity and innovation to flourish. This capability is paramount in modern architecture where bespoke solutions are often required to meet aesthetic and functional demands. Trustworthiness, a cornerstone of reliable machinery, is another critical aspect of these machines. Reputable manufacturers of door and window section roll forming machines invest heavily in research and development, ensuring their products not only comply with international safety standards but also exceed them. These machines are subjected to rigorous quality assurance tests to corroborate their durability and performance under varying operational conditions. Such due diligence provides confidence to buyers, knowing that their investment is safeguarded by comprehensive warranties and widespread service support networks. Direct interactions with industry professionals reinforce the perception of roll forming machines as investment assets. Testimonials from satisfied users espouse their transformative impact on production capabilities, while case studies highlight significant improvements in output quality and reductions in operational costs. These endorsements amplify the trust placed in these machines and underscore their value proposition. In conclusion, the door and window section roll forming machine stands as an exemplar of industrial evolution. Its integration of advanced technology, versatile functionality, and cost-efficiency builds a compelling case for its indispensability in modern construction. Through experience, expertise, authoritativeness, and trustworthiness, it holds the promise of transforming manufacturing processes, delivering products that align with both contemporary and future demands. As industries advance, the role of such machinery will undoubtedly continue to expand, crafting the frameworks for tomorrow’s world.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products