Custom Roll Forming Solutions for Volcometal Parante Products and Applications

Custom Roll Former for Volcometal Parante A Game Changer in the Metal Fabrication Industry

The rise of advanced manufacturing technologies has transformed the landscape of countless industries, and metal fabrication is no exception. One notable innovation is the custom roll former, which has become an essential tool in the production of specialized metal products. Volcometal Parante, a leader in metal solutions, exemplifies the advantages of utilizing this technology in its operations. This article delves into how a custom roll former can revolutionize production processes, enhance product quality, and promote operational efficiency.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of metal is gradually shaped into the desired cross-section. The process utilizes a series of rollers and dies, which carefully guide the metal through progressive stages, ultimately resulting in a finished product. Custom roll forming refers to tailoring these rollers and dies to meet specific requirements, thereby allowing manufacturers to create unique profiles that suit their customers' needs.

The Significance of Customization

The ability to customize roll forming machinery provides a significant competitive edge. For businesses like Volcometal Parante, this means not only the capability to produce tailored shapes but also the flexibility to adapt to changing market demands. Custom roll formers can accommodate various metal types, gauges, and dimensions, ensuring that manufacturers can produce a wide range of products, from structural components to decorative elements.

Moreover, custom roll forming allows for the creation of complex designs that might be impossible or economically unfeasible with traditional manufacturing techniques. This versatility satisfies the increasing demand for personalized products, enabling businesses to stand out in a crowded market.

Enhancing Product Quality

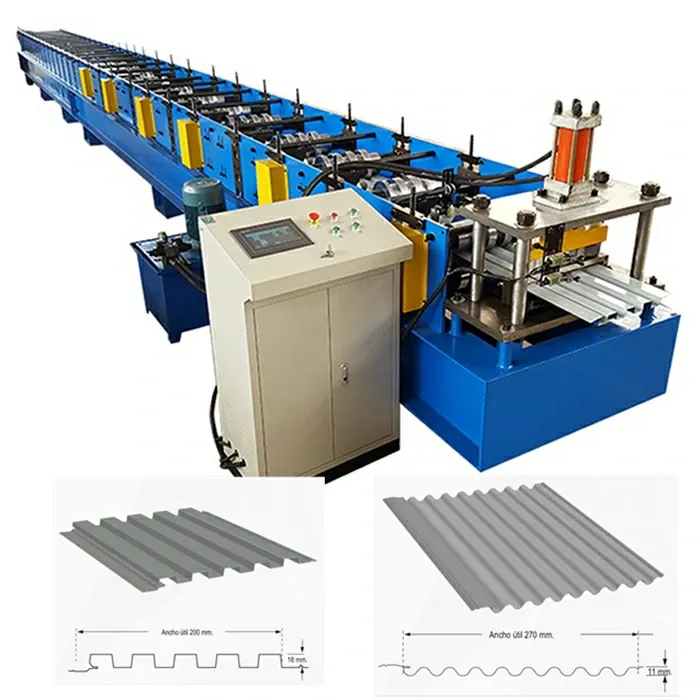

custom roll former for volcometal parante

One of the paramount benefits of using a custom roll former is the enhancement of product quality. Roll forming results in a uniform and consistent finish, significantly reducing material waste and increasing yield. The process eliminates the need for secondary operations, such as welding or cutting, which can introduce inconsistencies and defects.

When working with Volcometal Parante, customers can expect precision-engineered components that meet strict quality standards. The consistency in thickness, shape, and finish achieved through custom roll forming not only enhances the aesthetic appeal but also improves the overall structural integrity of the products. As a result, businesses can deliver reliable components that enhance the longevity and performance of their final products.

Optimizing Operational Efficiency

In today's fast-paced manufacturing environment, operational efficiency is crucial. Custom roll formers can vastly improve production speed without sacrificing quality. The continuous nature of the roll forming process means that large quantities of components can be produced in a relatively short time frame. This efficiency is amplified when manufacturing custom products, as setup times can be minimized with the right machinery in place.

Additionally, custom roll formers require less manual intervention compared to other methods, such as stamping or pressing. This reduction in labor not only cuts costs but also lowers the risk of human error, leading to a more streamlined production process. For companies like Volcometal Parante, these factors translate into faster turnaround times, allowing them to respond promptly to customer demands.

Conclusion Embracing the Future of Metal Fabrication

As the metal fabrication industry continues to evolve, the integration of technology such as custom roll formers will play a pivotal role in shaping its future. Companies like Volcometal Parante are at the forefront of this change, leveraging cutting-edge solutions to deliver high-quality, customized products efficiently.

The significance of customization in today's market cannot be overstated, as consumers increasingly seek tailored solutions that meet their specific needs. By investing in custom roll forming technology, manufacturers can enhance product quality, optimize operations, and maintain a competitive edge in the ever-changing landscape of metal fabrication. As we look ahead, the partnership between innovative technologies and skilled craftsmanship will undoubtedly drive the industry forward, paving the way for a new era of manufacturing excellence.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025