custom floor deck forming machine

The Importance of Custom Floor Deck Forming Machines in Modern Construction

In the ever-evolving landscape of the construction industry, the necessity for efficient, reliable, and innovative machinery cannot be overstated. One such crucial piece of equipment that has gained prominence is the custom floor deck forming machine. These machines play a vital role in producing strong, lightweight floor systems that are essential for modern buildings, offering a perfect blend of durability and efficiency.

Understanding Floor Deck Forming Machines

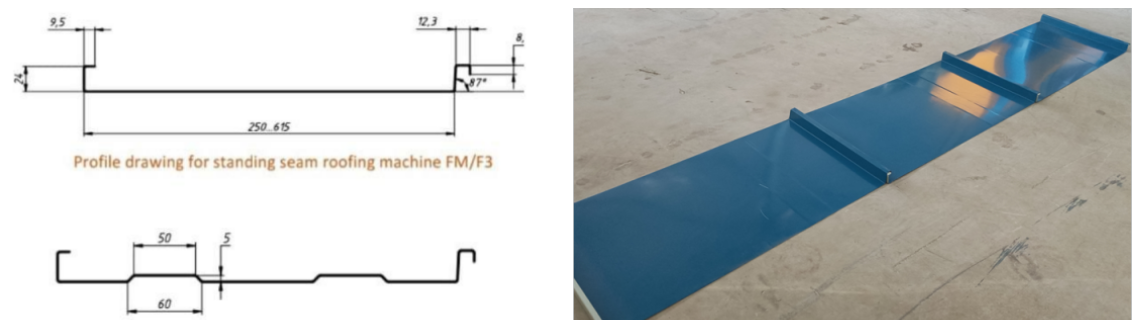

Floor deck forming machines are specialized equipment designed to manufacture floor decking systems from various materials, including steel, aluminum, and concrete. The process typically involves forming sheets or panels through the application of pressure and heat, enabling precise embossing, cutting, and shaping according to specified dimensions. These machines are tailored to produce various profiles and thicknesses, ensuring compatibility with diverse construction needs.

Customization A Key Advantage

One of the standout features of floor deck forming machines is their ability to be customized according to the requirements of specific projects. Different construction sites may demand unique floor designs, thicknesses, material types, and load-bearing capacities. Custom machines can be designed to accommodate these needs, leading to increased efficiency on the job site and improved overall project outcomes.

Customizability extends to the production speed as well. Depending on the scale of the project, contractors can opt for machines that can operate at various speeds, thus optimizing workflow. Enhanced production rates can significantly reduce timelines, allowing construction projects to progress smoothly and meet deadlines without compromising quality.

Efficiency and Cost-Effectiveness

The integration of custom floor deck forming machines in construction processes leads to marked efficiency gains. Traditional methods of flooring installation can be labor-intensive, requiring significant manual labor and time. In contrast, automated machines streamline these processes, minimizing human intervention and the potential for errors.

custom floor deck forming machine

Moreover, efficiency translates into cost savings. Less labor means lower expenses, and reduced materials wastage due to precision manufacturing directly results in better resource management. As construction budgets tighten, the demand for machines that offer both speed and cost-effectiveness has surged.

Enhanced Structural Integrity

Another important consideration in modern construction is the structural integrity of buildings. Custom floor deck forming machines produce high-quality materials that contribute to the overall strength of the floors. These machines can create ribbed or composite panels that enhance load distribution, offering added benefits for buildings facing heavy wear and tear, such as warehouses or industrial spaces.

The designs possible with these customized machines also allow for better integration with other structural elements of a building. This seamlessness contributes to the safety and durability of the structures, providing peace of mind to builders and occupants alike.

Recent Innovations in Technology

The landscape of floor deck forming machinery is continually advancing, with recent technological innovations enhancing capabilities further. Features such as computer numerical control (CNC) technology have enabled the precision of customizations and automation of the forming process, resulting in improved accuracy and efficiency. Additionally, advancements in materials science have allowed for lighter, stronger components that can withstand various environmental stresses while maintaining low weight.

Conclusion

The shift towards custom floor deck forming machines is not only a response to the complexities of modern construction but also a proactive approach to improving efficiency and building quality. By investing in such machinery, contractors can ensure they are well-equipped to handle the demands of contemporary projects, reducing both time and costs while enhancing the structural integrity of their buildings.

As the construction industry continues to evolve, the role of custom floor deck forming machines will undoubtedly grow in significance, paving the way for more innovative and resilient structures. Embracing these technologies is not just beneficial; it's imperative for those looking to thrive in the competitive construction landscape. Whether it's skyscrapers, residential buildings, or commercial spaces, the future of construction will be shaped by the capabilities and efficiencies offered by advanced machinery like customized floor deck forming machines.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025