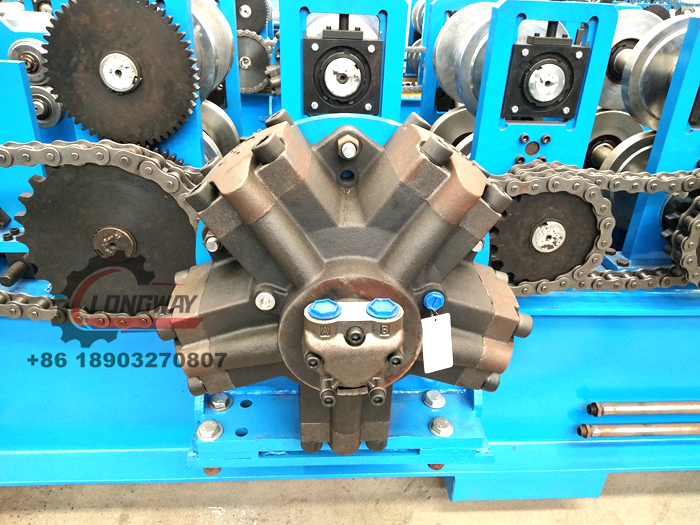

custom angle roll forming machine

Custom Angle Roll Forming Machine A Revolution in Metal Fabrication

In the ever-evolving world of manufacturing, the importance of precision and efficiency cannot be overstated. One of the standout innovations that have transformed metal fabrication processes is the custom angle roll forming machine. This specialized equipment is designed to produce high-quality metal sections with exceptional accuracy, catering to a diverse range of industries.

A custom angle roll forming machine operates on a straightforward yet effective principle it continuously feeds metal sheets into rollers that shape them into desired angles or profiles. The versatility of this machine allows manufacturers to create custom angles—be it L, U, or Z shapes—tailored to specific project requirements. This flexibility is crucial in industries such as construction, automotive, and aerospace, where precise specifications are vital for structural integrity and functionality.

One of the major advantages of using a custom angle roll forming machine is its efficiency. Traditional methods of metal fabrication often involve multiple processes, including cutting, bending, and welding, which can be time-consuming and labor-intensive. In contrast, the roll forming process streamlines these tasks into a single continuous operation. This not only significantly reduces production time but also minimizes material waste, contributing to a more sustainable manufacturing process.

custom angle roll forming machine

Moreover, the technology behind these machines has advanced in recent years, incorporating state-of-the-art automation and control systems. Operators can easily program the machine to produce a variety of profiles, with precise control over dimensions and tolerances. This automation reduces the likelihood of human error and ensures consistent quality across large production runs. By enhancing repeatability, manufacturers can confidently meet the needs of clients with varying volume requirements.

Another significant aspect is the cost-effectiveness of utilizing a custom angle roll forming machine. While the initial investment might be considerable, the long-term savings in labor, material waste, and operational efficiency usually outweigh the costs. Companies that adopt this technology often notice a robust return on investment as they can take on more complex projects without the need for extensive manual labor.

In conclusion, the custom angle roll forming machine stands as a testament to the advancements in metal fabrication technology. Its ability to produce high-quality, customized profiles efficiently makes it an invaluable asset for companies aiming to enhance their manufacturing capabilities. As industries continue to push for precision and speed, such machines will play a pivotal role in shaping the future of metalworking.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025