Manufacturer of Advanced Corrugated Roofing Sheet Forming Equipment and Solutions

Corrugated Roofing Sheet Forming Machine Manufacturer A Comprehensive Guide

In the ever-evolving construction industry, the demand for durable and reliable building materials has surged dramatically. Among these materials, corrugated roofing sheets have gained significant popularity due to their strength, lightweight, and cost-effectiveness. To meet this rising demand, manufacturers of corrugated roofing sheet forming machines have emerged as pivotal players in the market. This article explores the essential aspects of such manufacturers, their machines, and the benefits they bring to the construction sector.

Understanding Corrugated Roofing Sheets

Corrugated roofing sheets are sheet materials characterized by a series of ridges and grooves, which increase their structural strength while keeping the weight low. Typically made from metal, plastic, or fiberglass, these sheets are widely used in various applications, including residential buildings, commercial structures, and agricultural facilities. Their unique design provides excellent insulation, water resistance, and durability against harsh weather conditions.

The Role of Forming Machines

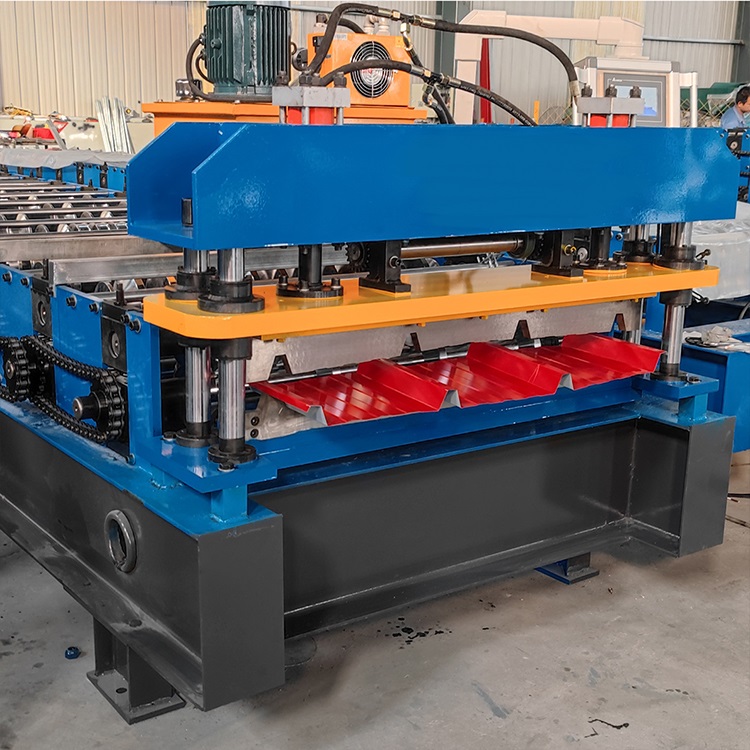

The manufacturing of corrugated roofing sheets demands precision and efficiency. This is where corrugated roofing sheet forming machines come into play. These machines are designed to produce sheets with consistent quality and dimensions, ensuring that buildings can rely on the materials for long-term performance.

The forming process typically involves feeding raw material, such as metal coils, into the machine, where it undergoes various stages of shaping, cutting, and rolling to produce finished corrugated sheets. Advanced machines integrate automation, which enhances production speed and reduces labor costs, making them a worthwhile investment for manufacturers.

Features to Look For in a Manufacturer

When searching for a corrugated roofing sheet forming machine manufacturer, several key features should be considered

1. Technology and Innovation The best manufacturers employ cutting-edge technology to ensure high-quality production. Machines with advanced features, such as programmable logic controllers (PLCs) and servo motor systems, enhance precision and improve the overall production process.

2. Customization Options Different projects may require specific sheet profiles and sizes. A reliable manufacturer should offer customizable solutions to meet various client needs.

corrugated roofing sheet forming machine manufacturer

3. Production Capacity Depending on market demand, the production capacity of the machine can be a critical factor. Manufacturers should provide machines with various capacities to cater to both small and large-scale operations.

4. Durability and Maintenance The longevity of forming machines is essential for continuous production. Manufacturers should provide machines built from high-quality materials that require minimal maintenance.

5. After-Sales Support Excellent customer service, including installation, training, and spare parts availability, is crucial for a smooth operation.

Benefits of Working with Professional Manufacturers

Opting for a professional corrugated roofing sheet forming machine manufacturer provides numerous advantages

- Quality Assurance Manufacturers with a proven track record provide machines that meet international standards, ensuring that the roofing sheets produced are of the highest quality.

- Cost Efficiency Investing in a reliable forming machine reduces the likelihood of production errors, minimizing waste and maximizing profit margins.

- Increased Production Speed Advanced forming machines significantly increase production speed, allowing companies to fulfill orders quickly and efficiently.

- Enhanced Flexibility Manufacturers can quickly adapt to changing market trends and demands by offering machines that can produce a variety of sheet designs and thicknesses.

Conclusion

As the demand for corrugated roofing sheets continues to grow, the importance of reliable corrugated roofing sheet forming machine manufacturers cannot be overstated. By focusing on advanced technology, customization, and after-sales support, these manufacturers play an essential role in providing high-quality roofing solutions that meet the needs of modern construction. Whether you are a contractor or a business owner in the construction industry, partnering with a reputable manufacturer can significantly impact the quality and efficiency of your projects. Investing in state-of-the-art corrugated roofing sheet forming machines not only enhances productivity but also contributes to the long-term success of any construction endeavor.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025